Catalog excerpts

Universal Design Printing - Laminating - Coating - Extrusion Converters can now have the best of all available surface treatment equipment configurations by implementing the Pillar Universal station. This advanced technology features a patented design of easily interchangeable magazines and ground rolls to allow operation as a bare roll (conductive substrates); covered roll (non-conductive substrates); or dual-dielectric (delicate substrates) system. Patented Modular Interchangeable Electrode Magazine electrodes on the Universal station can be replaced or interchanged in a matter of seconds. Slide the segmented stainless steel magazine out and the ceramic tube magazine in, now you’re ready to run with a dual dielectric conguration. Take out the covered roll and replace with a bare roll, now you can run conductive substrates. This patented modular magazine approach makes cleaning and changeout effortless with minimal downtime. Special Electrode Mounting of the Electrode Assemblies The Universal magazine design enables each material to thermally expand at its own rate without causing electrode warping or changes in gap, ensuring even treatment across the web. Special electrode mounting prevents electrical shorts due to the carbonizing of build up, thus reducing excessive spare parts inventories clean up time, and maintenance. Bare Roll Universal Covered Roll Universal Interchangeable Electrode Assemblies Enhanced Universal Stainless steel segmented electrodes (available in nominal 3 mm, 6 mm, 12,5 mm) now allow operators using dielectric covered rolls the exibility to treat various web widths and “lane” treat while achieving higher treat levels. Stainless Steel Segmented (Adjustable Treat Widths) Stainless steel finned electrodes are used in conjuction with dielectric covered ground rolls for high efcient treatment of non-conductive materials with a xed width or lane treatment requirement. Stainless Steel Finned Ceramic round or square electrodes are designed for converters looking to treat metallized, thin or sensitive substrates utilizing either bare roll or dual-dielectric surface treatment technology. Ceramic Tube surface treatment solutions Pillar Technologies • 475 Industrial Drive • P.O. Box 110 • Hartland WI 53029-0110 • USA • 1-888-PILLAR-6 • treaters@pillartech.co m • www.pillartech.com Copyright © 2010

Open the catalog to page 1

Universal Design Printing - Laminating - Coating - Extrusion External Gap Adjust with Micrometer Gap adjustments become as elementary as turning a dial, reducing set-up time. Patented Pneumatic Electrode Thread Up Mechanism This feature is designed to pivot electrodes out of the way for easy thread up. The unique design also enables knots and splices to move easily through the gap without breaking the web or damaging the electrode. Easy Roll Removal This unique system incorporates slotted end plates with access covers to make roll changeovers quick and simple. Roll Coverings The Universal...

Open the catalog to page 2All Pillar technologies catalogs and technical brochures

-

Foiler Cadet™

1 Pages

-

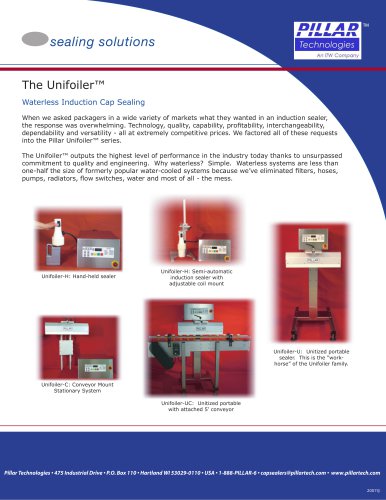

The Unifoiler™

2 Pages

-

VERSATreat

1 Pages

-

IntellaDyne

2 Pages

-

p6000

2 Pages

Archived catalogs

-

Induction Cap Sealing

2 Pages