Website:

Pietro Galliani Brazing Spa

Website:

Pietro Galliani Brazing Spa

Catalog excerpts

PIETRO GALLIANI BRAZING S.p.A. Società Unipersonale Via Molino Malpasso, 65 40038 Vergato (BO) Italy Tel: +39 051 910061 Fax +39 051 7417223 info@pietrogallianibrazing.com www.pietrogallianibrazing.com

Open the catalog to page 2

Cadmium-free Silver Based Alloys Copper Phosphorus and Copper Phosphorus Silver Alloys Brass and Aluminium Alloys Soft Solders

Open the catalog to page 3

WELCOME TO PIETRO GALLIANI BRAZING OVER 100 YEARS OF EXPERIENCE IN THE CREATION OF BRAZING ALLOYS More than 1000 products made completely in Italy RESEARCH AND INNOVATION 100% MADE IN ITALY AT THE SERVICE OF HIGH-TECH PIETRO GALLIANI BRAZING S.p.A. is the largest European manufacturer of brazing alloys, with over 100 years of experience in the production of high quality products. We have a selection of products able to satisfy every specific need in the world of brazing, with our wide range of alloys in the form of: bare and coated rods, wires, sheets, rings, preforms and paste or doseable...

Open the catalog to page 4

OUR HISTORY PIETRO GALLIANI BRAZING S.p.A. has been operating in the metallurgical sector for over 100 years. Since 1995 it has distinguished itself as a European leader in the production of materials for brazing, made 100% in the factories located in Vergato, at about 50 kilometres south of Bologna. Through continuous R&D activity and constant attention to product quality, we are able to supply our clients with all the main alloys and fluxes used in the world of brazing, at the same time, developing, producing and promoting all the related products and services

Open the catalog to page 5

PIETRO GALLIANI BRAZING OUR MISSION Our goal is to create a partnership with our clients and support them in optimising their production processes. PIETRO GALLIANI BRAZING S.p.A. is situated at the foot of the Apennines, on the banks of the Reno river. Being in such close contact with the territory makes us even more respectful of the environment that hosts us, and even more committed to promoting sustainability in every action we undertake. La PIETRO GALLIANI BRAZING S.p.A. is certified UNI EN ISO 9001:2015 e UNI EN ISO 14001:2015. Our products respect the norms AWS A5.8, EN 1044, EN...

Open the catalog to page 6

OUR SERVICES CUSTOMISED TECHNICAL SUPPORT Our experts are at your disposal: - to find the most effective solutions to problems that may arise during processing - to carry out micrographs and metallographic analyses of the brazed joint (tolerances, joint design, capillarity) - to develop new products, also in partnership with your R&D department - to develop automation in the production process PACKAGING DESIGN (CUSTOMISED SOLUTIONS) TRAINING (IN BRAZING TECHNIQUES) We are able to deliver your products ready for sale, creating high quality labels and packaging with your company logo and...

Open the catalog to page 7

INSTRUCTIONS FOR USE TECHNICAL INFORMATION Brazing is a process by which two metal parts are stably joined by the use of a filler material which is brought to fusion through the application of heat, this filler material penetrates in a capillary way between the joints to be united, connecting them definitively. Brazing, unlike welding, does not unite the two metal parts by melting them, but instead unites them by melting the filler material, which by capillarity penetrates the two metal parts to join them in a stable and permanent way. The filler material must always have a lower melting...

Open the catalog to page 8

HOW TO CHOOSE THE ALLOY FOR BRAZING The alloy for the brazing (the so-called “brazing alloy”) has to be chosen considering various aspects, including the characteristics of the materials to be joined and their melting point. In fact, the alloy must melt at a lower temperature than the base metals, to avoid deterioration of the other materials involved in the operation. The field of application of the finished product is also important, in fact, there are alloys that have a higher resistance to environments particularly subject to corrosion, or alloys that are more suitable for jewellery...

Open the catalog to page 9

CADMIUM-FREE SILVER BASED ALLOYS They are low temperature brazing alloys, for general use and suitable for joining base materials such as iron, carbon steel, stainless steel, copper, nickel and the alloys of these metals. Given the fluidity and excellent capillary penetration capacity, they ensure joints with excellent mechanical characteristics and resistance to pressure and vibrations. Fluidity Excellent capillary penetration capacity Excellent mechanical characteristics

Open the catalog to page 10

Other elements

Open the catalog to page 11

COPPER PHOSPHORUS AND COPPER PHOSPHORUS SILVER ALLOYS They are successfully and widely used in sanitary piping systems because, not containing zinc, they do not incur the risk of “dezincification”. The presence of phosphorus greatly helps to reduce the formation of oxides during the heating and brazing process. The addition of silver, in addition to phosphorus, guarantees a better mechanical resistance of the joint (especially in tensile stress), these alloys cause a slight loss of wettability during brazing. Brazing of these alloys is carried out through rapid heating with a torch thanks...

Open the catalog to page 12

Other elements International Norms

Open the catalog to page 13

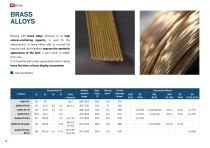

BRASS ALLOYS Brazing with brass alloys, because of its high atomic-scattering capacity, is used for the characteristic of being better able to conceal the brazing itself and therefore improve the aesthetic appearance of the joint, a joint which is hidden from view. It is therefore particularly appreciated when making brass furniture or brass display accessories. Joint aesthetics Other elements Solidus -liquidus range

Open the catalog to page 14

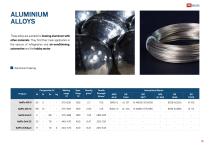

ALUMINIUM ALLOYS These alloys are suitable for brazing aluminum with other materials. They find their main application in the sectors of refrigeration and air-conditioning, automotive and the hobby sector. Aluminium brazing Composition % Product International Norms

Open the catalog to page 15

TRIFOILS TRI-TECH Tri-Tech is the ideal product for the brazing of hard metals, especially when brazing the teeth of saws. Tri-Tech is produced by the coupling of two sheets of silver alloys with a copper sheet in the centre, which thanks to particular technology and a specific very high pressure lamination, permits the coupling of the three sheets until a single layer is obtained. The final product allows the brazing of hard metals which satisfies all the requirements of sealing and mechanical and shock resistance needed, characteristics essential for the applications for which the tool is...

Open the catalog to page 16