Catalog excerpts

Pictures and technical features are not binding. The company reserves the right to modify the features of its products without notice. Registered trademarks. Advertising material © copyright. All rights reserved. MINERAL FUEL & LUBE OIL Via Don Battistoni, 1 - 60035 Jesi (AN) Italy Phone +39 0731.2311- Fax +39 0731.231239 www.pieralisi.com - info@pieralisi.com

Open the catalog to page 1

Mineral fuel & lube oil Mineral fuel and lube oil derived from crude oil are a commodity strongly related to many businesses operating costs and environmental impacts. This is the reason why many companies are exploring new technologies to extend the use of oils, reduce maintenance and increase the recovery rate. Pieralisi offers technological solutions for fuels cleaning and treatment, for lube oils purification, for the conditioning and recovery of mineral oils, industrial or environmental slop oils, bottom tank residues and bilge water. Furthermore, our easy and efficient solutions are...

Open the catalog to page 2

Mineral fuel & lube oil: Processes 1 Refinery/Industrial Oily Waste Collecting System Oily Water Preliminary Strainer Oily Sludge Storage Tank Magnetic Unit Stirred Tank Oily Waste Mineral fuel & lube oil: Processes Heat Recovery Additive Aeration Tank Separation Page 8-10 Solids Water Water Purification Page 16 Purified Oil Water Solids Waste and washing water treatment Process section involving Pieralisi technologies Example of process flow diagram Waste and washing water treatment Process section involving Pieralisi technologies Example of process flow diagram

Open the catalog to page 3

Mineral fuel & lube oil: Processes Solvent Water Mineral fuel & lube oil: Processes Guard Filter Screen and Guard Filter Heating Heating Additive Separation Page 8-10 Waste and washing water treatment Process section involving Pieralisi technologies 4 Lagoon and Sedimentation Pond Treatment Waste and washing water treatment Example of process flow diagram 6 Liquid Fuel Purification and Conditioning Fuel Tank Guard Filter Screen and Filter Additive Homogenization Tank Example of process flow diagram Process section involving Pieralisi technologies Heating Solids Clean Fuel Waste and washing...

Open the catalog to page 4

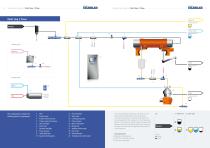

GRUPPO GRUPPO 8 Mineral fuel & lube oil: Single Step 2 Phase PIERHLISI Mineral fuel & lube oil: Single Step 2 Phase RIERHLISI Single Step 2 Phase Product 4. Additive group -------------- > Additive Solid TYPICAL QUALITY Heating system Water Oil emulsion TYPICAL QUALITY Fuel This configuration includes the 1. Filter following pieces of equipment: 2. Product pump 3. Heat exchanger 4. Static mixer 5. Decanter centrifuge 6. Oil emulsion tank 7. Oil emulsion pump 8. Screw conveyor 9. Main control panel 10. Mixing tank 11. Additive solution pump 13. Steam generator 14. Heating system control...

Open the catalog to page 6

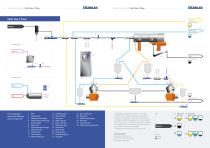

Mineral fuel & lube oil: Single Step 3 Phase Mineral fuel & lube oil: Single Step 3 Phase Single Step 3 Phase Product Additive group Water Steam TYPICAL quality Light phase-oil TYPICAL quality This configuration includes the following pieces of equipment: Steam Water Filter Product pump Heat exchanger Static mixer 3 phase decanter centrifuge Water phase tank Water phase pump Oil phase tank Heavy phase-water TYPICAL quality Oil phase pump Screw conveyor Main control panel Mixing tank Additive solution pump Flow meter Steam generator Heating system control panel The treatment unit based on a...

Open the catalog to page 7

GRUPPO GRUPPO 12 Mineral fuel & lube oil: Single Step 3 Phase - low solid content RIERHLISI Mineral fuel & lube oil: Single Step 3 Phase - low solid content Single Step 3 Phase - low solid content Product 3. 13. Additive group ft r?-, Additive Heating system TYPICAL QUALITY This configuration includes the 1. Filter following pieces of equipment: 2. Product pump 3. Heat exchanger 4. Static mixer 5. Centrifugal separator 6. Clean oil tank 8. Solid discharge tank 9. Solid pump 10. Main control panel 11. Mixing tank 12. Additive solution pump 13. Flow meter 14. Steam generator 15. Heating...

Open the catalog to page 8

Mineral fuel & lube oil: Multi Step 2 Phase Mineral fuel & lube oil: Multi Step 2 Phase Multi Step 2 Phase Clean oil TYPICAL QUALITY TYPICAL QUALITY Water Steam Solid TYPICAL QUALITY Additive Water Steam Heating system Steam Water TYPICAL QUALITY This configuration includes the following pieces of equipment: Filter Product pump Product-oil heat recovery Product-water heat recovery Heat exchanger Static mixer Decanter centrifuge Screw conveyor Liquid phase tank Separator feeding pump Heat exchanger Static mixer Centrifugal separator Clean oil pump Main control panel Mixing tank Additive...

Open the catalog to page 9

Mineral fuel & lube oil: Multi Step 3 Phase Mineral fuel & lube oil: Multi Step 3 Phase Multi Step 3 Phase Clean oil TYPICAL QUALITY Additive group TYPICAL QUALITY Water Steam TYPICAL QUALITY Heating system Water Steam Steam Water TYPICAL QUALITY This configuration includes the following pieces of equipment: Filter Product pump Product-oil heat recovery Product-water heat recovery Heat exchanger Static mixer 3 phase decanter centrifuge Water phase tank Oil phase tank Screw conveyor Water feeding pump Oil feeding pump Heat exchanger Static mixer Water separator Clean water tank Clean water...

Open the catalog to page 10

Mineral fuel & lube oil: Components Mineral fuel & lube oil: Components Centrifugal separator Decanter centrifuge Pieralisi decanter centrifuges are based on a modern technology that combines the ability of treating high solids content products with an excellent clarification efficiency. Separation performances are related not only to mechanical details but also to operating parameters (centrifugal force, flow rate, differential speed, liquid levels) and to the specific characteristics of the product (density, viscosity, quantity and dimension of solid particles). A main motor connected to...

Open the catalog to page 11All Pieralisi - Separation Solutions Division catalogs and technical brochures

-

Company profile ENG

34 Pages

-

Fruit and Vegetables Juice

12 Pages

-

Animal based products

12 Pages

-

Vegetable milks

6 Pages

-

Environmental Applications

10 Pages