Catalog excerpts

Pictures and technical features are not binding. The company reserves the right to modify the features of its products without notice. Registered trademarks. Advertising material © copyright. All rights reserved. FRUIT AND VEGETABLE JUICE Via Don Battistoni, 1 - 60035 Jesi (AN) Italy Phone +39 0731.2311- Fax +39 0731.231239 www.pieralisi.com - info@pieralisi.com

Open the catalog to page 1

mm mm ■ Fruit and vegetable juice Juices extracted from fruit and vegetable are vital to hydrate and keep our body healthy. They enable the preservation of corporeal pH, the prevention of disorders and diseases. The choice of raw material is as important as the necessary technologies for processing and obtaining high quality products. The great experience, acquired over the years from Pieralisi Group, offers a wide range of solutions for the extraction of fruit or vegetable juices and puree, granting the best nutritional quality of the finished product. Our wide range of separators and...

Open the catalog to page 2

GRUPPO GRUPPO 2 Fruit and vegetable juice: Processes RIERHLISI Fruit and vegetable juice: Processes RIERHLISI 3 1 Citrus fruit juice Product ■v Process section involving Pieralisi technologies Waste and washing water treatment Tank bottoms recovery Example of process flow diagram Process section involving Pieralisi technologies Example of process flow diagram

Open the catalog to page 3

Fruit and vegetable juice: Processes 3 Apple and pear juice Fruit and vegetable juice: Processes 4 Peach, apricot, prune, kiwi juice Depulping Grinding Pre-heating and enzymatic treatment Purée Fibers, peel Pre-heating and enzymatic treatment Purée Homogenization 2nd Extraction Page 14 Juice Fibers Pasteurization Packaging Clarified juice Pasteurization Concentration and final treatment Packaging Waste and washing water treatment Tank bottoms recovery Process section involving Pieralisi technologies Waste and washing water treatment Tank bottoms recovery Example of process flow diagram...

Open the catalog to page 4

Fruit and vegetable juice: Processes Fruit and vegetable juice: Processes 6 Mango, guava, papaya, lychee juice Depulping Squeezing Pre-heating and enzymatic treatment Pre-heating and enzymatic treatment Fibers, seeds Fibers, seeds Optional Clarification Page 14 Optional Clarification Page 14 Clarified juice Concentration Fibers Pasteurization Packaging Clarified juice Pasteurization Packaging Waste and washing water treatment Tank bottoms recovery Process section involving Pieralisi technologies Example of process flow diagram Process section involving Pieralisi technologies Example of...

Open the catalog to page 5

Fruit and vegetable juice: Processes 7 Tomato and carrot juice Fruit and vegetable juice: Processes 8 Grape juice Product Peeling (only for carrots) Pre-heating and enzymatic treatment 1st stage pulping 2nd stage pulping (only for tomatoes) Fibers, peel 2 extraction juice Pre-heating and enzymatic treatment Optional Fibers, peel Clarified juice Pasteurization Packaging Sterilization Fibers Packaging Waste and washing water treatment Tank bottoms recovery Process section involving Pieralisi technologies Waste and washing water treatment Tank bottoms recovery Example of process flow diagram...

Open the catalog to page 6

Fruit and vegetable juice: Processes Washing Selection Depulping Pulp Water Grinding Peel pressing Secondary juice Thermic pre-treatment Juice Thermic pre-treatment Juice Optional Juice Clarification Page 14 Clarified juice Concentration ultrafiltration Sterilization Packaging Waste and washing water treatment Tank bottoms recovery Process section involving Pieralisi technologies Example of process flow diagram

Open the catalog to page 7

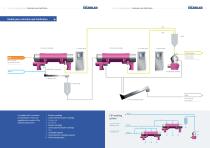

Fruit and vegetable juice: Extraction and clarification Fruit and vegetable juice: Extraction and clarification Juice extraction and clarification TYPICAL VALUES Clarified juice TYPICAL VALUES Solid TYPICAL VALUES 7. Solid conveying system A complete line for extraction and clarification of fruit and vegetable juice consists of the following components: 1 . Decanter centrifuge 2 . Control panel for decanter centrifuge 3 . Back-pressure valve 4 . Tank 5 . Centrifugal separator 6 . Control panel for centrifugal separator 7 . Solid conveying system CIP washing system Washing circuit Flushing...

Open the catalog to page 8

Fruit and vegetable juice: Extraction and clarification Fruit and vegetable juice: Extraction and clarification Double juice extraction and clarification Juice Juice 7. Tank Clarified juice TYPICAL VALUES TYPICAL VALUES Solid: fibers, seeds, peel 3. Mixing scroll 4. Stirred tank Solid 10. Solid conveying system A complete line for extraction and clarification of fruit and vegetable juice consists of the following components: 1 . Decanter centrifuge 2 . Control panel for decanter centrifuge 3 . Mixing scroll 4 . Stirred tank 5 . Decanter centrifuge 6 . Control panel for decanter centrifuge 7...

Open the catalog to page 9

Fruit and vegetable juice: Recovery of essential oils Fruit and vegetable juice: Recovery of essential oils Essential oils concentration and purification Water Oil emulsion TYPICAL VALUES Solid TYPICAL VALUES A complete line for concentration and purification of essential oils consists of the following components: 1 . Stirred tank 2 . Centrifugal separator 3 . Control panel for centrifugal separator 4 . Tanks 5 . Centrifugal separator 6 . Control panel for centrifugal separator CIP washing system Washing circuit Flushing circuit

Open the catalog to page 10

Fruit and vegetable juice: Components Fruit and vegetable juice: Components Centrifugal separator Decanter centrifuge Pieralisi decanter centrifuges are based on a modern technology that combines the ability of treating high solids content products with an excellent clarification efficiency. Separation performances are related not only to mechanical details but also to operating parameters (centrifugal force, flow rate, differential speed, liquid levels) and to the specific characteristics of the product (density, viscosity, quantity and dimension of solid particles). A main motor connected...

Open the catalog to page 11

Decanter centrifuge rc ^ So cu.ti ROTATING ASSEMBLY MATERIALS EXECUTION LUBRICATION PROCESS CONFIGURATION DRIVES DECANTER OPTIONS PLANT OPTIONS Centrifugal separator

Open the catalog to page 12All Pieralisi - Separation Solutions Division catalogs and technical brochures

-

Company profile ENG

34 Pages

-

Mineral fuel and lube oil

12 Pages

-

Animal based products

12 Pages

-

Vegetable milks

6 Pages

-

Environmental Applications

10 Pages