Catalog excerpts

Single-Position Glove/Sleeve, Blanket, Stick/Hose/Hood Testing Equipment PHENIX Testing Applications Used to test the dielectric breakdown and leakage current of personal protection equipment and devices for utility workers ➤ Economical, portable, compact design ➤ Manually operated ➤ Powered by external high voltage source, ➤ Complies with IEC, ASTM, and OSHA standards Single-position Glove/Sleeve Test Chamber • Perform testing on class 00 to class 4 Rubber Gloves or Sleeves according to the latest editions of ASTM, IEC and OSHA standards. • Test chamber is constructed of 12-gauge cold-rolled steel, primed and coated with two urethane paint topcoats, has hinged, front access door with acrylic window, a polyethylene water tank, and casters. • Electrical interlocks on test compartment access door shut down the output voltage if any entry is attempted while under test. • HV tank and cabinet are grounded when voltage is off. • Direct free air intake and circulation system via exhaust fan, draws clean air across the water surface to remove ozone build-up generated during testing. • Sleeve testing is accomplished by the straight method utilizing a dielectric fluid as a cuff seal which sits at the bottom of the tank. • Dimensions: 55” (1397 mm) L x 35” (889 mm) W x 76” (1930 mm) H Weight: 510 lbs (231 kgs) • Powered and operated via AC Hipot Model 6CP50/10-3 (see brochure# 60701) or Model BK130/36 (see brochure# 60208) • Zero Start Interlock • Failure indicating lights • Any failure requires operator to reset the test set to resume test • Refer to AC Hipot brochure for electrical specifications Specifications are subject to change w

Open the catalog to page 1

Single-position Blanket Test Fixture • Perform testing on multiple classes of Rubber Blankets • HV and return terminals to connect power supply up to 46” (1168 mm) in width or length. Meets standard ASTM-F479 for new and in-service rubber blankets • The enclosure is made of electrical grade fiberglass • Equipped with safety disconnect switches for and collapses into a convenient size with handles that allow for easy mobility. All parts are stored inside in folded position except for electrodes. • Lower electrode positioned in bottom of enclosure with latches. Upper electrode positioned in...

Open the catalog to page 2

Single-position Stick/Hose/Hood Test Rack • Perform testing on Hot Sticks up to 8’ (2.4 m) or • Includes one hose test fixture (customer provides sample hose) • Each 4’ (1.2 m) Rack features clear, fold-up safety • Dimensions & Weight for a single rack section: covers, carrying handles, removable wheels, and includes vinyl cover • Racks are connected in series to test longer lengths • Powered and operated via AC Hipot Model • Equipped with safety disconnect switches for operator protection • Spring-type electrodes positioned on 6” (152 mm) centers • HV and return terminals to connect power...

Open the catalog to page 3

PHENIX Technologies is committed to providing leadership, innovation, technology, quality, and service in all areas of our business. Our 85,000 square-foot headquarters is a modern manufacturing facility. All aspects of electrical, mechanical, and software design and production are performed in this facility. Our engineers offer a unique blend of theoretical knowledge and practical experience. Our Service and Calibration Department assists customers during and after installation to ensure years of trouble free service. We carry our commitment into the future as we proudly continue to...

Open the catalog to page 4All PHENIX TECHNOLOGIES INC catalogs and technical brochures

-

Motor_Core_Loss_Testers

4 Pages

-

Discharge_Ground_Sticks

2 Pages

-

Modular_DC_Hipots_100-600kV

4 Pages

-

Portable_DC_Hipots_40-200kV

4 Pages

-

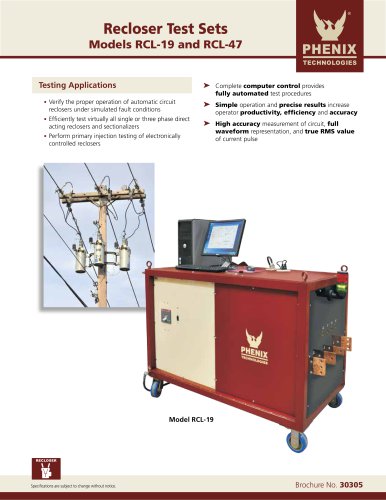

Recloser_Test_Sets

4 Pages

-

Current_Transformer_Tester

2 Pages

-

Winding_Resistance_Meter

2 Pages

-

Insulation_Analyzers

4 Pages

-

Liquid_Dielectric_Test_Sets

4 Pages

-

Rubber_Goods_Washer_Dryer

2 Pages

-

Automatic_Ratio_Tester

2 Pages

-

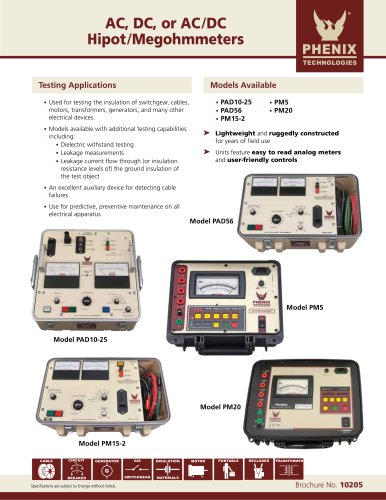

AC_DC_Hipot_Megohmmeters

4 Pages