Catalog excerpts

Permabond single-part epoxy adhesives are suitable for bonding a wide variety of materials. They are available with a range of different viscosities and characteristics. Permabond epoxies have been developed to offer a high standard of performance for demanding applications. Substrates Permabond single-part epoxy adhesives will bond most engineering materials They form excellent structural bonds to a wide variety of materials including metals, composites, ferrites and some plastics. Durability These adhesives offer excellent performance at high temperatures and harsh environmental conditions, having superb resistance to many aggressive chemicals. Applications Single-part epoxies are ideal for use in heavy wear-and-tear applications such as bonding tungsten carbide tools & machinery. They are ideal for replacing welding and brazing and can significantly reduce assembly production costs. For this reason their use is widespread in the heat exchanger bonding market for sealing heat exchanger tubes and end-plates. Material selection By replacing welding or brazing, the designer can have greater freedom of choice of manufacturing materials and can bond dissimilar substrates together. This can help reduce component cost and weight as well as improve performance. Process These adhesives are available in cartridge form or in bulk to dispense via automated dispensing equipment. They fully cure rapidly when exposed to heat via the use of an oven, induction coil, infra-red or hot air gun. Joint Design Joint design possibilities are greatly improved by the high shear and peel strength of joints bonded with these adhesives and by the increased stress distribution that they offer. Benefits ■ High peel strength increases design versatility ■ No requirement for weighing or mixing material ■ Durability increases material choices ■ Rapid full cure increases production rates ■Solvent free improves workplace safety ■ Low odour improves workplace environment ■ Excellent high temperature resistance and can withstand harsh environmental conditions ■An effective alternative to welding or brazing

Open the catalog to page 1

This table represents a selection of the complete range of Permabond single-part epoxy adhesives. For more detailed technical information and product Material Safety Data Sheets, visit www.permabond.com. To discuss your specific application requirements, please call the Permabond Helpline and our technical advisors will recommend the best adhesive for you or discuss the development of a new grade or product modification to meet your technical requirements. Permabond Epoxy Adhesives Comparison Chart Permabond Worldwide Wherever your manufacturing or R&D site may be located, Permabond...

Open the catalog to page 2All Permabond catalogs and technical brochures

-

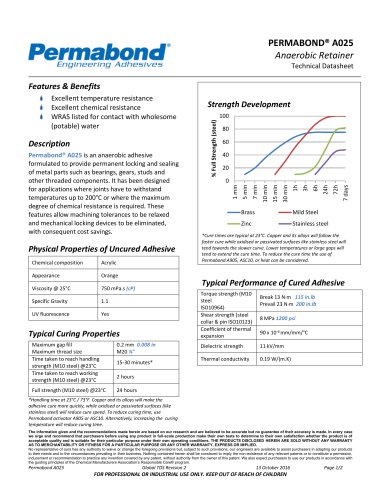

A025

2 Pages

-

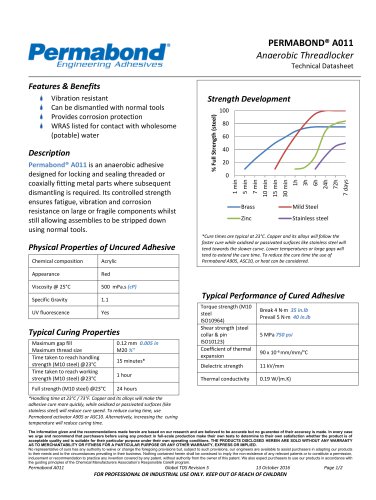

A011

2 Pages

-

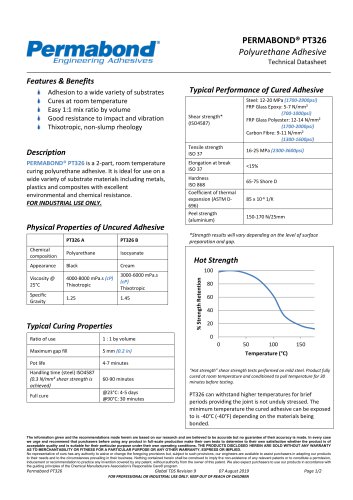

PT326

2 Pages

-

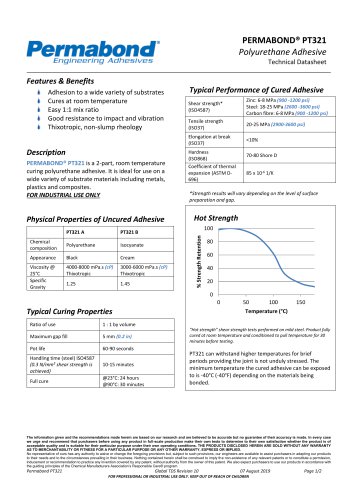

PT321

2 Pages

-

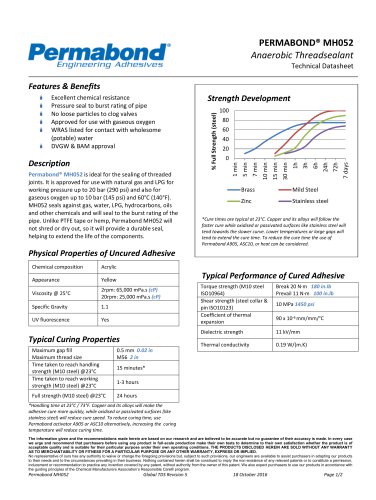

MH052

2 Pages

-

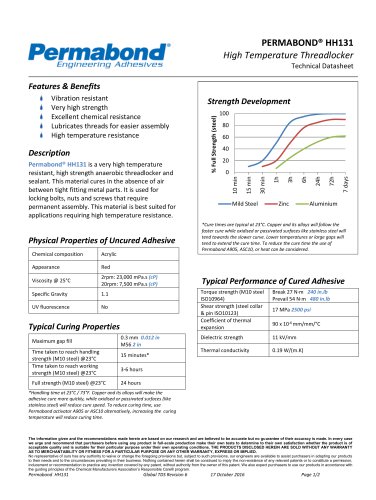

HH131

2 Pages

-

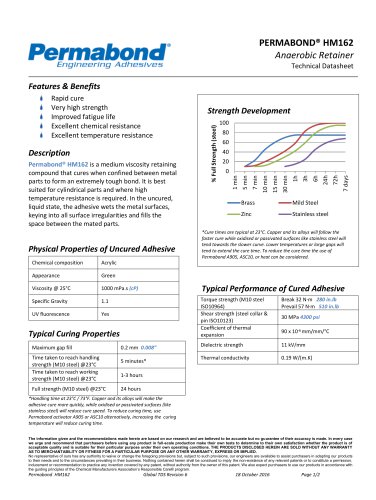

HM162

2 Pages

-

HM161

2 Pages

-

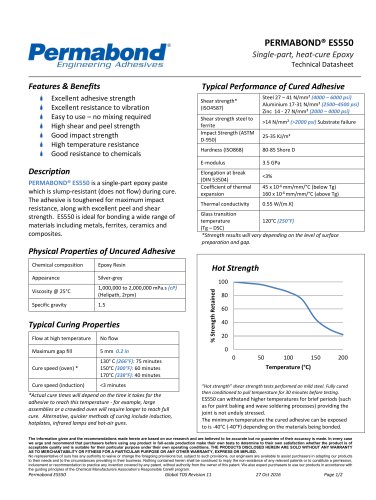

ES550

2 Pages

-

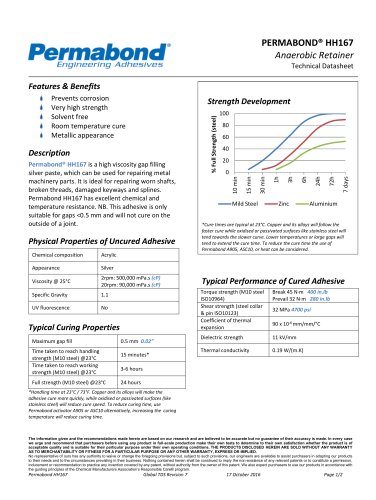

HH167

2 Pages

-

Polyurethane Adhesives

2 Pages

-

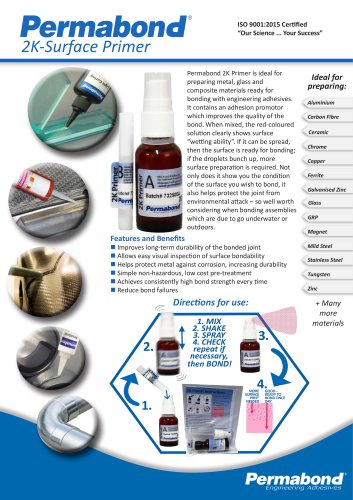

2K-Surface Primer

2 Pages

-

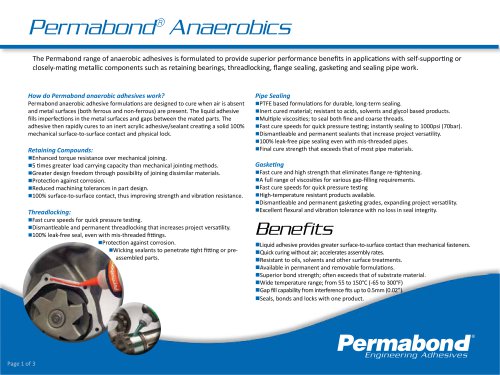

Permabond® Anaerobics

3 Pages

-

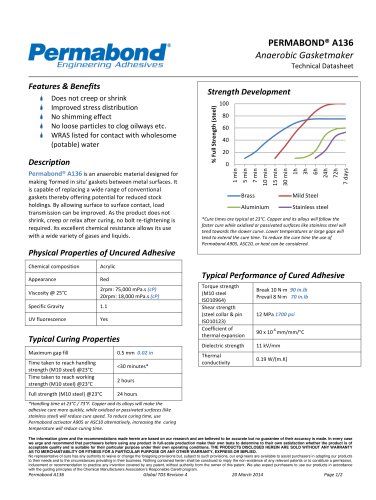

A136

2 Pages

-

2-Part Epoxie

2 Pages

-

Structural Acrylics

3 Pages

-

Flexible Adhesives

2 Pages

Archived catalogs

-

Single-Part Epoxies

2 Pages