Catalog excerpts

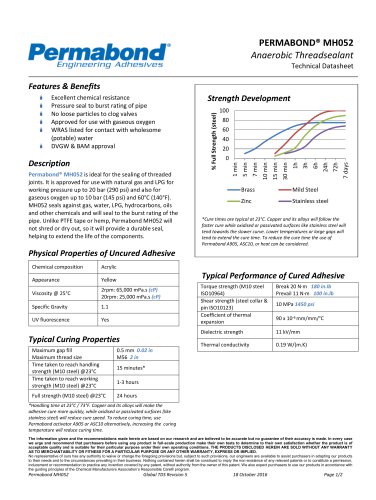

PERMABOND® MH052 Anaerobic Threadsealant Technical Datasheet Features & Benefits Mild Steel Stainless steel Permabond® MH052 is ideal for the sealing of threaded joints. It is approved for use with natural gas and LPG for working pressure up to 20 bar (290 psi) and also for gaseous oxygen up to 10 bar (145 psi) and 60°C (140°F). MH052 seals against gas, water, LPG, hydrocarbons, oils and other chemicals and will seal to the burst rating of the pipe. Unlike PTFE tape or hemp, Permabond MH052 will not shred or dry out, so it will provide a durable seal, helping to extend the life of the components. Strength Development % Full Strength (steel) Excellent chemical resistance Pressure seal to burst rating of pipe No loose particles to clog valves Approved for use with gaseous oxygen WRAS listed for contact with wholesome (potable) water DVGW & BAM approval *Cure times are typical at 23°C. Copper and its alloys will follow the faster cure while oxidised or passivated surfaces like stainless steel will tend towards the slower curve. Lower temperatures or large gaps will tend to extend the cure time. To reduce the cure time the use of Permabond A905, ASC10, or heat can be considered. Physical Properties of Uncured Adhesive Chemical composition Specific Gravity Typical Performance of Cured Adhesive Typical Curing Properties Maximum gap fill Maximum thread size Time taken to reach handling strength (M10 steel) @23°C Time taken to reach working strength (M10 steel) @23°C Full strength (M10 steel) @23°C Torque strength (M10 steel ISO10964) Shear strength (steel collar & pin ISO10123) Coefficient of thermal expansion Break 20 N·m 180 in.lb Prevail 11 N·m 100 in.lb Dielectric strength Thermal conductivity *Handling time at 23°C / 73°F. Copper and its alloys will make the adhesive cure more quickly, while oxidised or passivated surfaces (like stainless steel) will reduce cure speed. To reduce curing time, use Permabond activator A905 or ASC10 alternatively, increasing the curing temperature will reduce curing time. The information given and the recommendations made herein are based on our research and are believed to be accurate but no guarantee of their accuracy is made. In every case we urge and recommend that purchasers before using any product in full-scale production make their own tests to determine to their own satisfaction whether the product is of acceptable quality and is suitable for their particular purpose under their own operating conditions. THE PRODUCTS DISCLOSED HEREIN ARE SOLD WITHOUT ANY WARRANTY AS TO MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY OTHER WARRANTY, EXPRESS OR IMPLIED. No representative of ours has any authority to waive or change the foregoing provisions but, subject to such provisions, our engineers are available to assist purchasers in adapting our products to their needs and to the circumstances prevailing in their business. Nothing contained herein shall be construed to imply the non-existence of any relevant patents or to constitute a permission, inducement or recommendation to practice any invention covered by any patent, without authority from the owner of this patent. We also expect purchasers to use our products in accordance with the guiding principles of the Chemical Manufacturers Association’s Responsible Care® program.

Open the catalog to page 1

Surface Preparation Though the anaerobic adhesives will tolerate a slight degree of surface contamination, best results are obtained on clean, dry and grease free surfaces. The use of a suitable solvent-based cleaner (such as acetone or isopropanol) is recommended. In general, roughened surfaces (~25μm) give higher bond strengths than polished or ground surfaces. To reduce the curing time, especially on inactive surfaces (such as zinc, aluminium and stainless steel), the use of Permabond A905 or ASC10 can be considered. % Strength Retained Temperature (°C) High Temperature Grades “Hot...

Open the catalog to page 2All Permabond catalogs and technical brochures

-

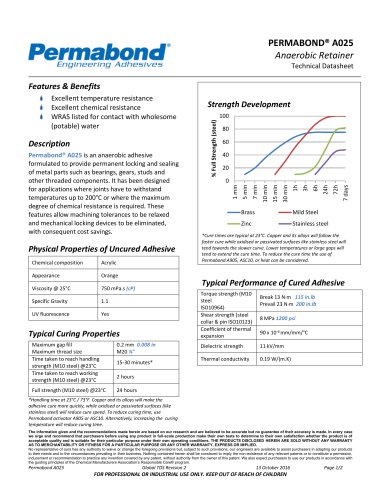

A025

2 Pages

-

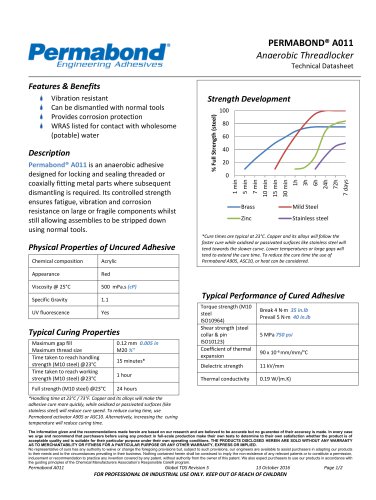

A011

2 Pages

-

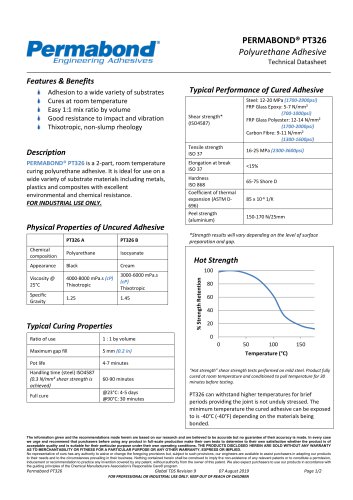

PT326

2 Pages

-

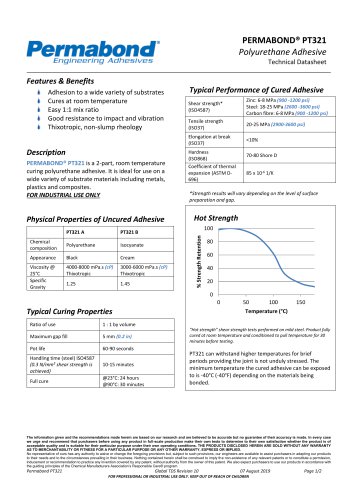

PT321

2 Pages

-

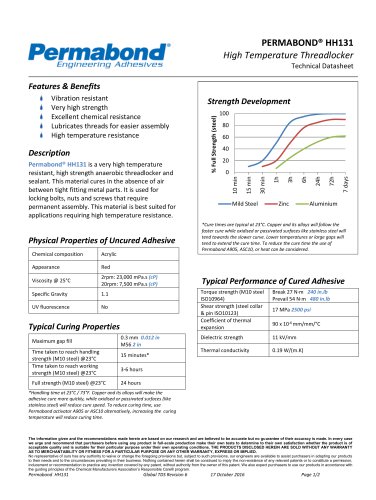

HH131

2 Pages

-

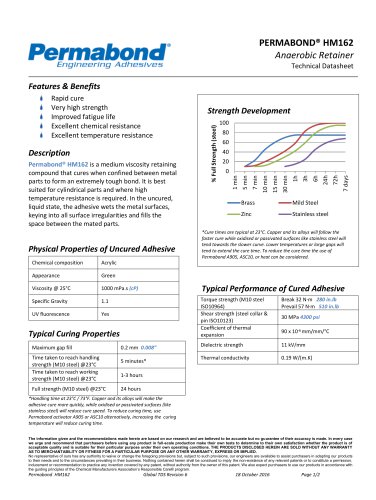

HM162

2 Pages

-

HM161

2 Pages

-

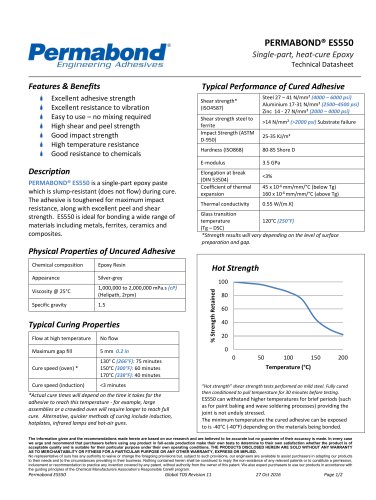

ES550

2 Pages

-

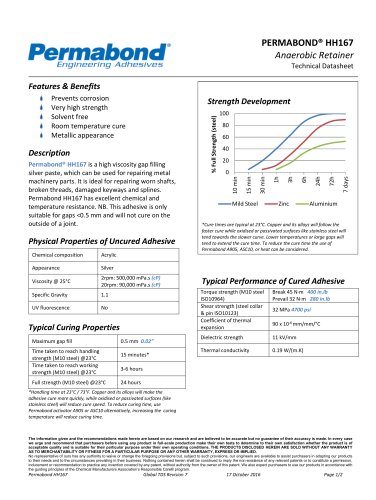

HH167

2 Pages

-

Polyurethane Adhesives

2 Pages

-

Single Part Epoxies

2 Pages

-

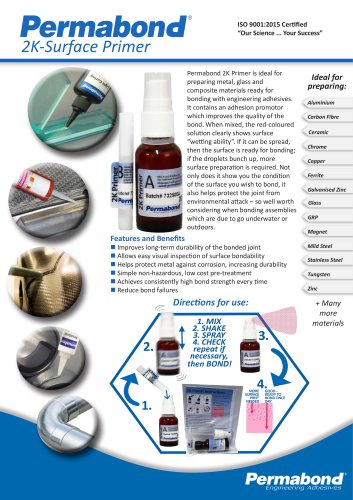

2K-Surface Primer

2 Pages

-

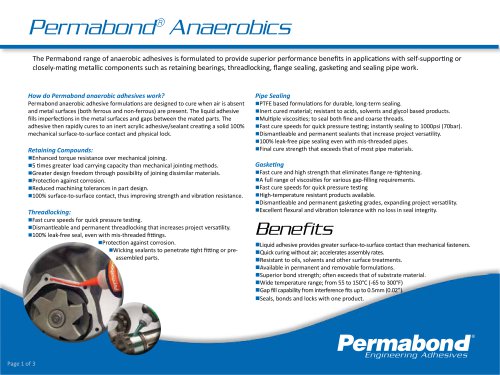

Permabond® Anaerobics

3 Pages

-

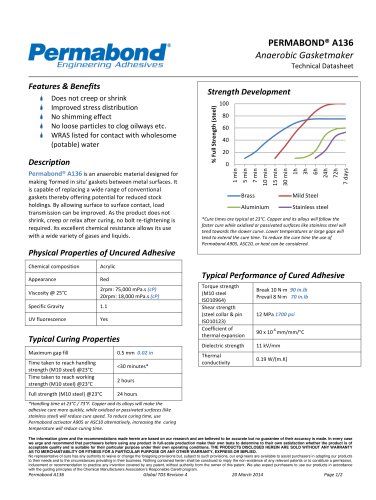

A136

2 Pages

-

2-Part Epoxie

2 Pages

-

Structural Acrylics

3 Pages

-

Flexible Adhesives

2 Pages

Archived catalogs

-

Single-Part Epoxies

2 Pages