Catalog excerpts

4SR 4” submersible pumps PERFORMANCE RANGE • • CERTIFICATIONS Flow rate up to 375 l/min (22.5 m³/h) Head up to 405 m APPLICATION LIMITS • • • • • • • Maximum liquid temperature +35 °C Maximum sand content 150 g/m³ 100 m immersion limit Installation: – vertical – horizontal, with the following limits: 4SR1 - 4SR1.5 - 4SR2 - 4SR4 up to 27 stages 4SR6 - 4SR8 - 4SR10 - 4SR12 - 4SR15 up to 17 stages Starts/hour: 20 at regular intervals Minimum flow rate for motor cooling 8 cm/s Continuous service S1 CONSTRUCTION AND SAFETY STANDARDS ELECTRIC MOTOR – Single-phase 230 V - 50 Hz – Three-phase 400 V - 50 Hz Length of power cable: – 1.5 m for powers from 0.37 to 1.5 kW (3 kW 4SR-FK) – 2.5 m for powers from 2.2 to 5.5 kW (from 4 kW to 7.5 kW 4SR-FK) – 3.5 m for power from 7.5 kW 4SR-PD ➠ The 4SR-PD single-phase versions come with a capacitor included in the packaging. EN 60335-1 IEC 60335-1 CEI 61-150 202 EN 60034-1 IEC 60034-1 CEI 2-3 INSTALLATION AND USE Suitable for use with clean water with a sand content of no more than 150 g/m³. As a result of their high efficiency and reliability, they are suitable for use in domestic, civil and industrial applications such as for the distribution of water in combination with pressure sets, for irrigation, for washing plants and for pressure boosting in fire-fighting sets, etc. PATENTS - TRADE MARKS - MODELS • • Patent Pending n° PCT/EP2009/059855 (cable cover) Patent Pending n° PCT/IB2009/051491 (for single-phase 4SR-PD up to 0.75 kW; three-phase up to 1.1 kW). OPTIONALS AVAILABLE ON REQUEST • Other voltages or 60 Hz frequency GUARANTEE 2 years subject to terms and conditions

Open the catalog to page 1

50 Hz n= 2900 1/min Head H (metres) PERFORMANCE RANGE 4SR1 4SR1.5 4SR2 4SR4 4SR6 4SR8 4SR10 4SR12 4SR15 Flow rate Q DESCRIPTION 4 SR 1 m / 13 - PD or FK or HYD Borehole diameter in inches Series Flow rate in m3/h at the point of highest efficiency Single-phase motor Number of stages PD: pump with “PEDROLLO” motor FK: pump with “FRANKLIN” motor HYD: pump without motor 203

Open the catalog to page 2

4SR POS. COMPONENT 1 DELIVERY BODY CONSTRUCTION CHARACTERISTICS Precision cast stainless steel AISI 304, complete with threaded delivery port in compliance with ISO 228/1 1 2 NON-RETURN VALVE Stainless steel AISI 304 2 3 MOTOR BRACKET Stainless steel AISI 304, in compliance with NEMA standards 8 4 IMPELLER Lexan 141-R 5 DIFFUSER Noryl GFN2V 6 STAGE CASING Stainless steel AISI 304 7 PUMP SHAFT Stainless steel AISI 304 8 PUMP BEARINGS Special-technopolymer housing with stainless steel AISI 316, chrome oxide coated, sand resistant shaft bushing 4 5 6 11 9 9 DRIVE COUPLING Stainless steel AISI...

Open the catalog to page 12

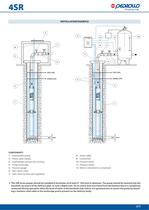

4SR INSTALLATION EXAMPLE 5 9 11 12 7 8 10 5 8 4 4 6 6 STATIC LEVEL STATIC LEVEL DYNAMIC LEVEL DYNAMIC LEVEL 3 2 2 1 1 min. 1 metre min. 1 metre COMPONENTS 1) Submersible pump 2) Power cable clamps 3) Level probes; prevent dry running 4) Pump anchorage 5) Pressure gauge 6) Non-return valve 7) Gate valve; for flow rate regulation 7 8) 9) 10) 11) 12) Power cable Control box Pressure vessel Pressure switch Electro valve/electro-compressor ➠ The 4SR series pumps should be installed in boreholes of at least 4” (100 mm) in diameter. The pump should be lowered into the borehole, by means of the...

Open the catalog to page 16All Pedrollo catalogs and technical brochures

-

PLURIJET 90-130-200

4 Pages

-

PKS

4 Pages

-

EASYPRO

2 Pages

-

6PD 6" submersible motors

2 Pages

-

6SR 6" submersible pumps

12 Pages

-

2CP Twin-impeller pumps

12 Pages

-

CP up to 11 kW Centrifugal pumps

10 Pages

-

General catalog 2010

404 Pages

Archived catalogs

-

catalog 2005

242 Pages