Catalog excerpts

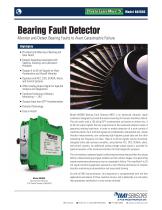

Bearing Fault Detector Monitor and Detect Bearing Faults to Avert Catastrophic Failure Highlights n Provides Early Warning of Bearing and Gear Faults Detects Impacting Associated with Spalling, Cracking, and Lubrication Problems Outputs 4 to 20 mA Signals for Peak Acceleration and Overall Vibration Operates with PLC, DCS, SCADA, Alarm, and Control Systems Offers Analog Output Signal for Spectral Analysis and Diagnostics Conducts Continuous Vibration Monitoring — 24/7 Accepts Input from ICP® Accelerometers Patented Technology Easy to Install Model 682B05 Bearing Fault Detector (BFD) is an advanced vibration signal conditioner designed to provide the earliest warning of imminent machinery failure. The unit works with a 100 mV/g ICP® accelerometer and serves to deliver two, 4 to 20 mA output signals that are proportional to the measured vibration levels of operating rotating machinery. In order to enable detection of a wide variety of machinery faults, the 4 to 20 mA signals are conditioned to characterize two, unique vibration measurements; one containing high frequency peak data and the other containing low frequency rms data. These 4 to 20 mA signals may be monitored, alongside other plant process variables, using familiar PLC, DCS, SCADA, alarm, and control systems. An additional analog voltage output signal is provided for spectral analysis of the monitored vibration for fault diagnostic purposes. The unit employs a patented signal conditioning technique that provides the unique ability to detect bearing and gear problems at their earliest stages, thus permitting ample maintenance planning to avert a catastrophic failure. The simplified 4 to 20 mA signal monitoring approach represents a cost effective alternative to complex vibration monitoring instrumentation and associated training. Model 682B05 Bearing Fault Detector *(US Patent Number 6,889,553) As with all IMI instrumentation, this equipment is complemented with toll-free applications assistance, 24-hour customer service, and is backed by a no-risk policy that guarantees satisfaction or your money refunded.

Open the catalog to page 1

Model 682B05 Introduction Machinery vibration monitoring has long been recognized as an effective practice for detecting mechanical problems that ultimately cause machinery failure and downtime. Unfortunately, many instrumentation systems that are intended to assist the maintenance engineer with vibration analysis are complex — and require considerable training and experience in order to interpret measurement data. Too often, companies may encounter the loss of an experienced maintenance engineer due to downsizing or attrition — leaving critical machinery to run without being monitored and...

Open the catalog to page 2

is a 4 to 20 mA signal proportional to overall, rms or peak vibration. Internal selection switches allow a choice of acceleration or velocity measurements, peak or rms values, and a variety of fixed measurement ranges. The signal generated by the accelerometer is initially processed through a 1 kHz low pass filter. Then when set for velocity, the BFD passes this filtered signal through an integration circuit. When set for acceleration, the filtered signal bypasses the integration circuit. At the next stage, the signal passes through a true RMS conversion circuit. Finally, a gain stage...

Open the catalog to page 3

Temperature Range (Operating) Temperature Range (Storage) Channels Input Signal (ICP® Accelerometer) POWER LED ANALOG OUTPUT Output Signals Raw, Analog Vibration Overall Vibration (range is user scalable) Captured Peak Acceleration (± 50 g) Measurement Range Raw, Analog Vibration Overall Vibration set for Acceleration (selectable) Overall Vibration set for Velocity (selectable) Captured Peak Acceleration Model 682B05 - Bearing Fault Detector Dimensions shown are in inches (millimeters) Frequency Range Raw, Analog Vibration Overall Vibration Captured True Peak Acceleration Time Constant /...

Open the catalog to page 4All PCB Piezotronics GmbH catalogs and technical brochures

-

Cables and Connectors

48 Pages

-

PAPER MACHINES & CONVEYORS

4 Pages

-

STEEL ROLLING & ANNEALING

4 Pages

-

4-20 mA Transmitters

20 Pages

-

PLATINUM STOCK SENSORS

20 Pages

-

MACHINE TOOL SPINDLES

4 Pages

-

Bearing Fault Detector

4 Pages

-

PLATINUM STOCK SENSORS

20 Pages

-

MESURES ACOUSTIQUES

4 Pages

-

IMI-HazArea-LowRes

2 Pages

-

686B series

8 Pages

-

Smart Vibration Sensors

4 Pages

-

Platinum Stock Products

4 Pages

-

Series 660

4 Pages

-

Data Collector Poles

2 Pages

-

Vibration Switches

12 Pages

-

Bearing Fault Detector PLUS

2 Pages

-

IMI Sensors - Gearboxes

4 Pages

![603 Series ICP® Accelerometers (Models [CS][EX]603CXX)](https://img.directindustry.com/pdf/repository_di/111589/603-series-icp-accelerometers-models-cs-ex-603cxx-673860_1mg.jpg)

![Industrial Triaxial ICP® Accelerometers (Models 604BXX and [EX]629AXX)](https://img.directindustry.com/pdf/repository_di/111589/industrial-triaxial-icp-accelerometers-models-604bxx-ex-629axx-673848_1mg.jpg)