Catalog excerpts

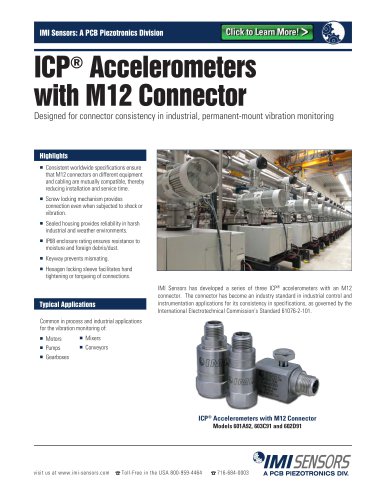

IMI Sensors - A PCB Piezotronics Division Mining Equipment Monitoring & Protection Solutions IMI Sensors offers reliability solutions to monitor and protect rotating mining assets against unscheduled catastrophic failures! Barge Pumps Conveyors Load-Out Facilities Crushers Shovels Draglines Trucks, Loaders & Scoops Overhead Hoists & Cranes Vibrating Screens Cooling Towers Pumps Bearings Gearboxes Motors

Open the catalog to page 1

Reliability, Up-Time and Safety Mining operation involves a variety of heavy rotating machinery that is used for exploration and processing of precious metals, minerals and material extracted from the earth. This industrial machinery is subjected to moderate, and in some cases, extreme vibration levels while in use. It's critical to trend these vibration levels to ensure equipment health / reliability and to avoid unscheduled catastrophic failures. IMI Sensors offers a full line of piezoelectric accelerometers, wireless solutions, transmitters, switches, enclosures, cable assemblies and...

Open the catalog to page 2

Mining Equipment Monitoring & Protection Underground Mining Approved Sensors Mining is inherently a dangerous industry where the health and safety is of the utmost importance to the miners and their organizations. Thus, the mining industry has invested a great deal of time and money to develop safety procedures and training to assure the health of their miners. Within the United States, The Mine Safety and Health Administration (MSHA) is dedicated to “Protecting Miners” by developing regulations that will assure the health and safety of the US miners. Organizations like MSHA are also found...

Open the catalog to page 3

Sensors for Hazardous and Extreme Environments Hazardous Area Approved Sensors Mining equipment reliability monitoring now requires instrumentation that is approved for hazardous environments. In addition to underground mining approved sensors (MSHA), IMI has a full line of PdM sensors and related technologies, such as intrinsic safety barriers that, when used together, will meet CSA and ATEX IS approvals. Sensors below may also be available in Temperature Output versions (prefix “TO”). Route Based Hazardous Approved Accelerometers Precision ICP® Accelerometer Hazardous Area Approved...

Open the catalog to page 4

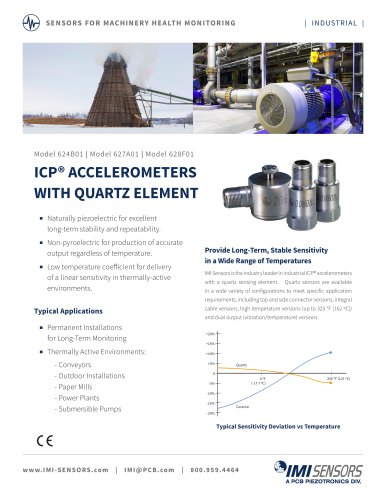

Mining Equipment Monitoring & Protection High Temperature Environments Best in Class Temperature Response Up to 325 °F (162 °C) In harsh, caustic, or high temperature areas, IMI Sensors offers a series of industrial sensors and cable assemblies that will withstand these rigorous environments. Cables and connectors made of material such as PTFE and FKM are available for higher temperature and/or caustic mining environments. Industry exclusive, ICP® sensors are available with temperature ratings up to 325 °F(162 °C). For temperatures greater than 325 °F (162 °C), IMI has designed charge...

Open the catalog to page 5

Wireless Vibration Wireless Sensors for Dangerous Areas Why have people risk injury and venture into unsafe areas to collect vibration data on healthy machines? IMI Sensors offers the Echo® Wireless Vibration Monitoring System that can automatically collect machinery health data in dangerous areas without having a miner venture into those areas. Using this alarm based system, personal intervention is only required when the system identifies a problem. Vibration Monitoring System Easily integrates with legacy vibration and plant monitoring systems via Modbus® Eliminates expensive cable runs...

Open the catalog to page 6

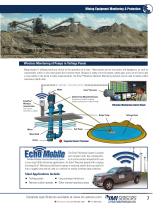

Mining Equipment Monitoring & Protection Wireless Monitoring of Pumps in Tailings Ponds Barge pumps in tailings ponds are critical to the operation of a mine. These ponds can be very acidic and dangerous, as well as inaccessible, which is why most plants don’t monitor them. Because it takes a host of people, safety gear, and a lot of time to get a crew safely to the pump to make measurements, the Echo® Wireless Vibration Monitoring System can be used to safely collect machinery health data. Echo® Receiver Cables From Mounted Sensors (connected to EchoPlus, enabling wireless transmission of...

Open the catalog to page 7

General Purpose Vibration Sensors Rugged, Robust, Accurate and Dependable! Route Based Precision Accelerometers t. Precision Single Axis ^ ■ High frequency response 15 kHz (+/-3dB) ■ Triaxial design (horizontal, vertical & axial measurement directions) ■ High frequency response 8 kHz (+/- 3dB) C£ Precision Single Axis ■ High frequency response 10 kHz (+/- 3dB) C £ Low Frequency Single Axis ■ Low frequency response down ■ Velocity output (VO) option available High Frequency Single Axis ■ High frequency response to 30 kHz (+/- 3dB) even with magnet ■ Ideal for measurements on high-speed...

Open the catalog to page 8

Mining Equipment Monitoring & Protection Permanently Installed Economical Accelerometers Low Cost ICP® Accelerometer Low Cost ICP® Accelerometer Low Cost ICP® Accelerometer Low profile thru bolt design IMI’s most popular side-exit low cost general purpose accelerometer Small installation footprint IMI’s most popular top-exit low cost general purpose accelerometer Low noise Low frequency response down to 16 cpm (+/- 3dB) Low Cost ICP® Accelerometer Low Cost ICP® Accelerometer Low Cost Triaxial Accelerometer IMI’s most economical sensor Submersible with extremely small installation footprint...

Open the catalog to page 9

& Vibration Switches Continuous monitoring and protection of critical assets has become a common practice in today's mining industry. IMI Sensors has developed such reliability solutions that meet these continuous monitoring needs by offering a series of Transmitters, Switches and Detectors that can be integrated within a facility's control room to monitor critical machinery ■ 24v loop powered that interfaces directly with a PLC, DCS and SCADA systems ■ Multiple ranges available or velocity output options Intrinsically Safe / explosion proof versions available C€ Reciprocating Machinery...

Open the catalog to page 10

Mining Equipment Monitoring & Protection Vibration Switches IMI’s new line of electronic vibration switches provides the total vibration monitoring package. Each model 685B vibration switch features 4-20 mA output, analog vibration analysis signal and dual relays with time delays standard. Our model 686B is simple and inexpensive two-wire USB programmable electronic vibration switch. The 686B vibration switch's programmable time delay eliminates false trips, making it a technically superior option to traditional mechanical shock switches. Electronic vibration switches are a great way to get...

Open the catalog to page 11All PCB Piezotronics GmbH catalogs and technical brochures

-

Cables and Connectors

48 Pages

-

PAPER MACHINES & CONVEYORS

4 Pages

-

STEEL ROLLING & ANNEALING

4 Pages

-

4-20 mA Transmitters

20 Pages

-

PLATINUM STOCK SENSORS

20 Pages

-

MACHINE TOOL SPINDLES

4 Pages

-

Bearing Fault Detector

4 Pages

-

PLATINUM STOCK SENSORS

20 Pages

-

MESURES ACOUSTIQUES

4 Pages

-

IMI-HazArea-LowRes

2 Pages

-

686B series

8 Pages

-

Smart Vibration Sensors

4 Pages

-

Model 682B05

4 Pages

-

Platinum Stock Products

4 Pages

-

Series 660

4 Pages

-

Data Collector Poles

2 Pages

-

Vibration Switches

12 Pages

-

Bearing Fault Detector PLUS

2 Pages

-

IMI Sensors - Gearboxes

4 Pages

![603 Series ICP® Accelerometers (Models [CS][EX]603CXX)](https://img.directindustry.com/pdf/repository_di/111589/603-series-icp-accelerometers-models-cs-ex-603cxx-673860_1mg.jpg)

![Industrial Triaxial ICP® Accelerometers (Models 604BXX and [EX]629AXX)](https://img.directindustry.com/pdf/repository_di/111589/industrial-triaxial-icp-accelerometers-models-604bxx-ex-629axx-673848_1mg.jpg)