Catalog excerpts

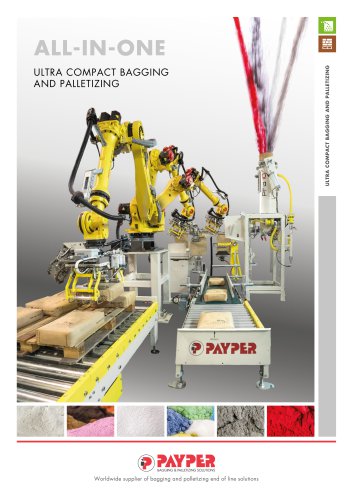

FORM FILL & SEAL BAGGING TECHNOLOGY Worldwide supplier of bagging solutions FORM FILL & SEAL BAGGING TECHNOLOGY

Open the catalog to page 1

FFS AUTOMATIC BAGGING MACHINES MODELS ASSAC The ASSAC Models bagging machines are designed to work with tubular roll films. The FFS concept Form, Fill & Seal means that all these functions, forming filling and sealing the bags, are executed within the same compact machine. This concept is very reliable, due to the fact that bags are hold during the whole process and only released once the entire process is finalized. ASSAC S10/15 400 bags/hour ASSAC S-10/15 are the gross weight version of the ASSAC models designed for low output capacity up to 400b/h or for products difficult to handle such...

Open the catalog to page 2

TYPICAL APPLICATION Max Output Installed Power kW Pneumatic consuption Nm3/h Granulated free flowing Fine granulate >200pm Powdery products PE Tubular film, Aluminium PE Laminated Bag length (Filled) Bag width w/o Gussets Filling weigths WEIGHING Net weight configuration SYSTEM Gross weight configuration DOSING SYSTEM

Open the catalog to page 3

STANDARD CONFIGURATION Film unwinding station. Film accumulator. Bag forming station (cutting and lower welding) Bag bottom cooling station. Bag filling station. Bottom compacting system. Bag sealing and bag cooling station. Bag exit belt. OPTIONAL FEATURES (ABBag corner sealing configurable system. Bag bottom filling system. (M Dearation probe for residual air. (5BAirwash bag top cleaner.

Open the catalog to page 4

All types of products. From very powdery to granules. AGRO-FOOD INDUSTRY BUILDING INDUSTRY CHEMICAL INDUSTRY PETROCHEMICAL INDUSTRY ALL THESE PRODUCTS AND MUCH MORE CAN BE PACKED WITH OUR ASSAC FFS TECHNOLOGY! CLEANABLE Bagging lines designed for easy cleaning in order to avoid bacteriological and cross-contamination. ATEX Upon customer request equipment can be manufactured and certified in order to be installed in classified ATEX area. ANTI CORROSION Different types of protection against corrosion are available in accordance to the aggressivity of the product and the environment. BOTTOM...

Open the catalog to page 5

OPTIONAL FEATURES FOR CORROSIVE PRODUCTS Various levels of protection are available such as different quality of the Stainless steel, heating systems, electric and pneumatic components housed, connectionless detectors...etc. FOR DUSTY PRODUCTS Special design has been created in order to avoid dust emissions featuring a airtight bagging spout and bottom filling system. This special design also prevents product segregation. FOR CLASSIFIED AREA / ATEX ZONE Adapted machine configuration allows installing the machine in a classified ATEX area in accordance to the relevant zone level and the...

Open the catalog to page 6

CORNER SEALING SYSTEM Option created in order to obtain a brick shaped bags for better palletizing, better over wrapping and better bag emptying. MOVABLE PLATFORM If needed the complete bagging installation could be mounted on a moving platform so that it could easily maneuver underneath different silo positions. ^uLuu r sdbicL <X>TabacaL *1* TATA TATA CHEMICALS LIMITED

Open the catalog to page 7

Permanent invesment in research and development Worldwide Technical Service J3 FSC www.fsc.ofg MIX Paper from responsible sources FSC* Cl 11142 SPAIN ■ FRANCE ■ MEXICO ■ BRAZIL ■ INDIA

Open the catalog to page 8All PAYPER catalogs and technical brochures

-

BIG BAG

8 Pages

-

CSA. Open Mouth Bag Placer

8 Pages

-

General Catalogue 2019

8 Pages

-

AUTOMATIC BAG PALLETIZERS

6 Pages