Catalog excerpts

Products Introduction

Open the catalog to page 1

Aiming for highly efficient production

Open the catalog to page 2

of machining――Work clamping system Dual cylinder

Open the catalog to page 3

Swing clamp Built-in air sensor model

Open the catalog to page 4

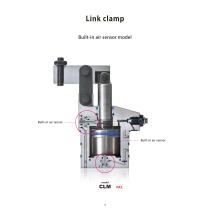

Link clamp Built-in air sensor model Built-in airair sensor Built-in sensor

Open the catalog to page 5

Swing clamp Built-in air sensor model

Open the catalog to page 6

25 MPa Link clamp Built-in air sensor model

Open the catalog to page 7

Work clamping system Standard model Work support Work support Work support Work support Flow control valve Swing clamp Link clamp Push cylinder

Open the catalog to page 8

Work clamping system Sensor model 7MPa Work lift cylinder Air swing clamp dual cylinder Boost air link clamp

Open the catalog to page 9

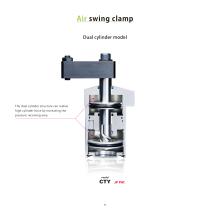

Air swing clamp Dual cylinder model The dual cylinder structure can realize high cylinder force by increasing the pressure receiving area.

Open the catalog to page 10

Air link clamp Boost model The boosting structure realizes high cylinder force. Downsized flange takes up minimum space keeping the clamping force the same.

Open the catalog to page 11

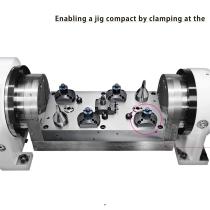

Enabling a jig compact by clamping at the

Open the catalog to page 12

bottom of workpiece――Expansion clamp

Open the catalog to page 13

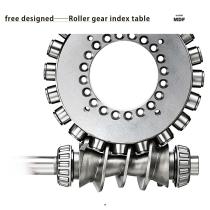

High speed, accurate and maintenance The roller gear where the pressurization is applied by rolling transmission has few abrasive wear and maintains non-backlash for a long term . The roller gear index table employs brake-less and non-backlash mechanism and cycle time can be improved . Hydraulic and pneumatic 9 ports & coolant 1 port are built-in . Clamp and loading operation can be confirmed with multiple circuits of rotary joint and machining line with excellent reliability can be realized . Roller gear index table model Support table model MDS Roller gear index table

Open the catalog to page 14

free designed――Roller gear index table

Open the catalog to page 15

Super compact positioning Locate ring Locate base

Open the catalog to page 16

Pal fix mini Locate ring model Locate ring model Locate base Locate base model Screw size Screw size Tapered surface Tapered surface Dual surface contact Seating surface Dual surface contact Seating surface

Open the catalog to page 17

For spindle unit of machining center Servo motor Servo motor Weight of spindle head N2 Gas Balance force (N2 gas balancer)

Open the catalog to page 19

High speed, accurate, long life Support table MDS130 Hydraulic oil /Air: 9 ports, Coolant: 1 port Base plate

Open the catalog to page 20

――Roller gear index table 0.5 sec. for 90 °indexing is realized without a brake Roller gear index table MDF130 Hydraulic oil /Air: 9 ports, Coolant: 1 port

Open the catalog to page 21

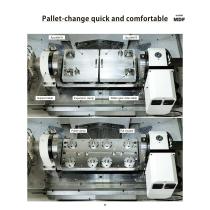

Quick jig change system Separated pallet Support table model Roller gear index table Another jig for different workpieces Swing clamp model Expansion clamp model Pallet clamp model

Open the catalog to page 22

Pallet-change quick and comfortable Jig pallet A Support table Roller gear index table Expansion clamp Pallet clamp

Open the catalog to page 23

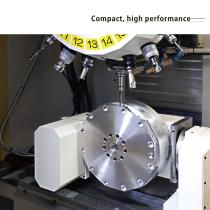

Compact, high performance――

Open the catalog to page 24

2-axis Roller gear index table It helps improve the productivity significantly by reducing takt time to 0.8 seconds per index with non-braking and high-speed rotation. ●Applicable for large workpieces with a max. diameter of 400mm ●9 built-in rotary joint ports for hydraulic and air +1 coolant port ensures flexibility and optimizes the workstation for workholding components. ●Suitable for small size machining centers (Weight 220kg) ●Its biaxial driving mechanism enables process integration so workpiece transferring can be reduced. ●A compact 2-axis index table with a width of 865mm ●The...

Open the catalog to page 25

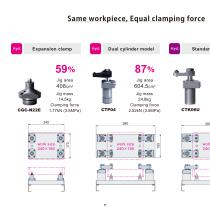

Same workpiece, Equal clamping force Expansion clamp Dual cylinder model Jig mass 14.5kg Clamping force 1.77kN (3.5MPa) Jig mass 24.8kg Clamping force 2.52kN (3.5MPa)

Open the catalog to page 26

Standard model Dual cylinder model Jig mass 26.5kg Clamping force 2.63kN (15MPa) Jig mass 31.6kg Clamping force 2.52kN (3.5MPa) Jig mass 37.5kg Clamping force 2.41kN (0.5MPa) Jig plate material : Steel, Thickness : 40mm 26

Open the catalog to page 27

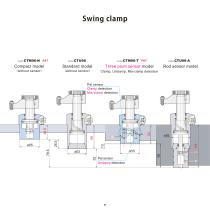

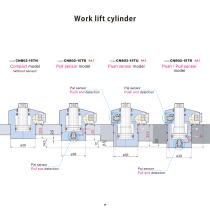

Swing clamp Compact model Standard model Three point sensor model ( without sensor ) ( without sensor ) Clamp, Unclamp, Mis-clamp detection Pal sensor Clamp detection Mis-clamp detection Pal sensor Unclamp detection

Open the catalog to page 28

Link clamp Compact model Standard model Three point sensor model ( without sensor ) ( without sensor ) Clamp, Unclamp, Mis-clamp detection Pal sensor Unclamp detection Pal sensor Clamp detection Mis-clamp detection

Open the catalog to page 29

Work lift cylinder Compact model Pull sensor model Push sensor model Push / Pull sensor model ( without sensor ) Pal sensor Push end detection Pal sensor Push end detection Pal sensor Pull end detection Pal sensor Pull end detectio

Open the catalog to page 30

Work support Plunger Lift spring Flow Control Valve Plunger Scraper Lift spring Scraper Taper sleeve Taper piston Taper piston Taper sleeve Hydraulic pressure ( manifold piping ) Base plate Piston Piston Hydraulic pressure 30

Open the catalog to page 31

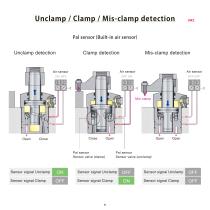

Unclamp / Clamp / Mis-clamp detection Pal sensor (Built-in air sensor) Unclamp detection Clamp detection Mis-clamp detection Pal sensor Sensor valve (clamp) Sensor signal Unclamp Sensor signal Clamp Pal sensor Sensor valve (unclamp) Sensor signal Unclamp Sensor signal Clamp Sensor signal Unclamp Sensor signal Clamp

Open the catalog to page 32

Detected mis-clamp Pressure switch Sensor model can prevent tool breakage and defective machining due to incomplete clamp May not be able to prevent machining defects perfectly Detected mis-clamp Pressure switch mis-detection Clamping point Clamping point Air sensor Pressure switch Miss clamping Clamp arm loose Wrong workpiec

Open the catalog to page 33

Swing clamp Dual cylinder model Flange area Dual cylinder Compact model Cylinder force Cylinder force

Open the catalog to page 34

Link clamp Dual cylinder model Flange area Dual cylinder Compact model Cylinder force Cylinder force

Open the catalog to page 35

Air swing clamp Dual cylinder model Flange area Dual cylinder Standard model Cylinder force Cylinder force

Open the catalog to page 36

Air link clamp Dual cylinder model Flange area Dual cylinder Standard model Cylinder force Cylinder force

Open the catalog to page 37

Boost air link clamp Flange area Boost model Standard model Cylinder force Cylinder force

Open the catalog to page 38

Boost air link clamp ③ Clamping force boosted Steel ball Taper Piston The rod and piston go up at the same time until a clamp arm contacts workpiece . ① Clamping force boosted Steel balls and taper can boost clamping force by the upward movement of piston . Piston Taper lock is securely unlocked by the downward movement of piston Piston The rod and piston go down at the sa

Open the catalog to page 39

Swing clamp Flat mount model Eliminating the embedding of the main body makes it easier to process the jig plate. Space-saving adjustment Swing clamp Flat mount model model Clamping hydraulic pressure Unclamping hydraulic pressure Since the embedded hole is not machined, the piping design under the clamp is easy and the jig plate can be made thin.

Open the catalog to page 40All Pascal Engineering Inc. catalogs and technical brochures

-

Pascal auto coupler

60 Pages

-

Pascal mold change system

68 Pages

-

Mold clamping system

136 Pages

-

Press machine system

48 Pages

-

Stamping die clamping system

254 Pages

-

Pascal N2 gas springs

28 Pages

-

mini Gas springs

40 Pages

-

N2 gas springs

86 Pages

-

Expansion clamp

142 Pages

-

air Work clamping system

130 Pages

-

35MPa Work clamping system

177 Pages

-

Pal system

106 Pages

-

7MPa Work clamping system

256 Pages

-

Pascal mag clamp

72 Pages