Catalog excerpts

Ensures high grade of the parts

Open the catalog to page 2

with high degree of accuracy

Open the catalog to page 3

N2 gas springs model list at a glance Standard model model model mode odell Compact body Dust seal Rod guide Dust seal

Open the catalog to page 4

High power, short stroke model model dell Long stroke Dust seal Dust seal Piston guide Piston seal Piston seal Piston & Rod guide Rod seal Piston & Rod guide

Open the catalog to page 5

mini gas springs model list at a glance Large diameter rod model High initial force Piston rod Dust seal Rod guide Check valve

Open the catalog to page 6

High durability against side-load model Compact body Dust seal Dust seal Check valve

Open the catalog to page 7

micro hose system It is high pressure gas piping system that is developed exclusively for N2 Gas spring. The micro hose system enables to install gas springs easily, securely and quickly. micro hose The hose is connectable just by tightening with fingers. ● Tools are not required for connecting micro hose. (Tool less) ● It can be tightened easily and quickly by hand.

Open the catalog to page 8

Structure of micro hose Specification of micro hose The hose will not loose even under high to vibration environments and maintains a secured sealing for a long term by adopting buttress thread and locking O-ring. Fluid used Proof pressure Operating temperature Hose 90°hose nut Straight adapter Inside diameter of hose Outside diameter of hose Minimum bending radius Hose core, outer coating : Polyamide resin Reinforcing layer:Aramid fiber Straight adapter Proof pressure varies according to the temperature of hose ● Sealing tape or agent should not be used for hose adaptor (gas pressure shall...

Open the catalog to page 9

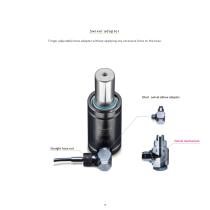

Swivel adapter Finger adjustable hose adapter without applying any excessive force to the hose. Short swivel elbow adapter Swivel mechanism Straight hose nut

Open the catalog to page 10

Tips for swivel adapter mounting 1. Mount a swivel adaptor on gas spring. 2. Mount a hose on swivel adaptor. The angle of hose is adjustable easily by turning a adaptor. Other Piping parts micro hose Straight adapter Swivel adapter Multi coupling block Control panel Hose clip, Plug

Open the catalog to page 11

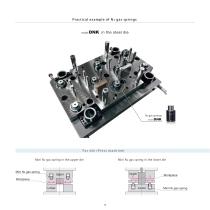

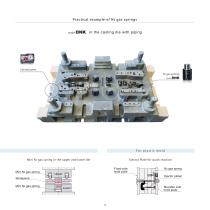

Practical example of N2 gas springs For die (Press machine) Mini N 2 gas spring in the upper die Mini N 2 gas spring in the lower die Workpiece Lower

Open the catalog to page 12

Practical example of N2 gas springs DNK in the casting die with piping Control panel N2 gas springs model For plastic mold Mini N 2 gas spring in the upper and lower die Ejector Plate for quick reaction Fixed side mold plate Ejector platen Workpiece Mini N2 gas spring Movable side mold plate

Open the catalog to page 13

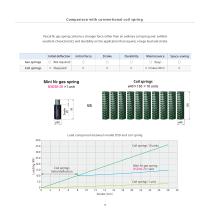

Comparison with conventional coil spring Pascal N2 gas spring contains a stronger force rather than an ordinary coil spring and exhibits excellent characteristics and durability on the application that requires a large load and stroke. Initial deflection Initial force ○(Not required) Coil springs Coil springs Load comparison between model DSD and coil spring 40.0 Coil springs 10 units Coil springs Initial deflection Coil springs 1 unit

Open the catalog to page 14

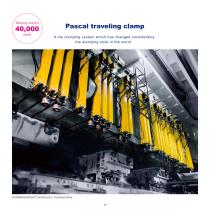

Delivery record Pascal traveling clamp A die clamping system which has changed considerably the stamping style in the world. 30,000kN(3,000tonf ) Transfer press Traveling clamp 16

Open the catalog to page 16

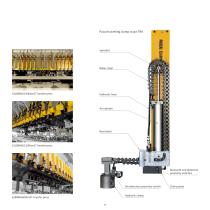

Pascal traveling clamp model TRA Roller chain Hydraulic hose Base block Backward end detection proximity switches Die detection proximity switch Hydraulic clamp Clamp plate

Open the catalog to page 17

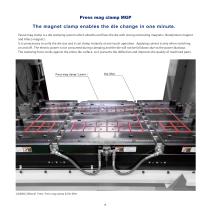

The magnet clamp enables the die change in one minute. Pascal mag clamp is a die clamping system which absorbs and fixes the die with strong everlasting magnets ( Neodymium magnet and Alnico magnet ). It is unnecessary to unify the die size and it can clamp instantly at one touch operation. Applying current is only when switching on and off. The electric power is not consumed during clamping and the die will not be fall down due to the power blackout. The clamping force works against the entire die surface, so it prevents the deflection and improves the quality of machined parts. Press mag...

Open the catalog to page 18

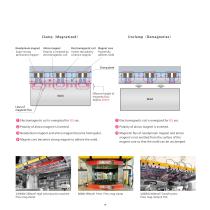

Neodymium magnet Super strong permanent magnet Alnico magnet Polarity is inverted by electromagnetic coil Electromagnetic coil Inverts the polarity of alnico magnet Magnet core Powerfully adheres mold Effective height of magnetic flux : Approx 20mm Lines of magnetic flux 1 Electromagnetic coil is energized for 0.5 sec. 1 Electromagnetic coil is energized for 0.5 sec. 2 Polarity of alnico magnet is inverted. 2 Polarity of alnico magnet is inverted. 3 Neodymium magnet and alnico magnet become homopolar. 3 Magnetic flux of neodymium magnet and alnico magnet is not emitted from the surface of...

Open the catalog to page 19

unit sales cost saving Stamping Die changer 3,000kN press Roller table with swing arm, independent pusher Guide Roller table Pusher head Pusher stand

Open the catalog to page 20

Stamping Die changer 3,000kN press Roller table With roller table and independent pusher Pusher head Pusher stand Operation control panel With pusher and swing roller arm Roller arm Pusher head Fixed roller table

Open the catalog to page 21

Slide lock The electric slide-fall protection system which eliminates the risk of physical injury accident or damages on the dies. Slide lock

Open the catalog to page 22

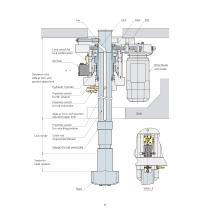

Limit switch for lock confirmation Oil Tank Drive Motor with brake A Distance to the slide at T.D.C with position upper limit Hydraulic Cylinder Proximity switch for 90°rotation Proximity switch for rod overstroke Slide Slide at T.D.C with position adjusted upper limit Proximity switch for unlocking position Lock stroke Screw rod (trapezoidal thread) Stopper for rod overstroke Stroke for head rotation

Open the catalog to page 23

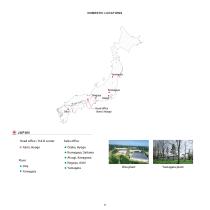

DOMESTIC LOCATIONS Kumagaya Nagoya Atsugi Head office (Itami, Hyogo) JAPAN Head office / R & D center Itami, Hyogo Sales office Osaka, Hyogo Kumagaya, Saitama Plant Oita Atsugi, Kanagawa Nagoya, Aichi Oita plant Yamagata plan

Open the catalog to page 24

GLOBAL NETWORK Stuttgart (Germany) Changchun Dalian Changwon (Korea) Tianjin Chongqing Shanghai Taichung(Taiwan) Kaohsiung (Taiwan) Ghaziabad (India) Wuhan Bangkok (Thailand) Queretaro,León (Mexico) Kuala Lumpur (Malaysia) Bekasi (Indonesia) Sao Paulo (Brazil) Melbourne (Australia) AMERICA Dalian[China] Queretaro, Leon[Mexico] Kuala Lumpur[Malaysia] ڠګڪڭڰڠ Stuttgart[Germany]

Open the catalog to page 25

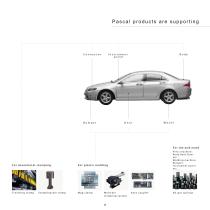

Pascal products are supporting Instrument panel Traveling clamp Mold die clamping system Press machine: B o d y, R o o f, D o o r etc... Molding machine: B u m p e r, Instrument panel etc... Auto coupler

Open the catalog to page 26All Pascal Engineering Inc. catalogs and technical brochures

-

Pascal auto coupler

60 Pages

-

Pascal mold change system

68 Pages

-

Mold clamping system

136 Pages

-

Press machine system

48 Pages

-

Stamping die clamping system

254 Pages

-

mini Gas springs

40 Pages

-

N2 gas springs

86 Pages

-

Pascal Products Introductions

76 Pages

-

Expansion clamp

142 Pages

-

air Work clamping system

130 Pages

-

35MPa Work clamping system

177 Pages

-

Pal system

106 Pages

-

7MPa Work clamping system

256 Pages

-

Pascal mag clamp

72 Pages