Catalog excerpts

Pascal mold change system

Open the catalog to page 1

Mold Clamps Overhead rane operations are hazardous.Mold change by There are very few employees per factory who can the changer table instead of the crane.→page 28 change molds, moreover, they may have many tasks on their hands. It is recommendable to create and work environment where anyone can change molds regardless of experience, gender, etc. Fewer skilled workers are available to operate cranes in a The time required to change molds and perform high level. In order to reduce crane operations as much maintenance on the machine means the machines stop, as possible"Automatic mold leveling...

Open the catalog to page 2

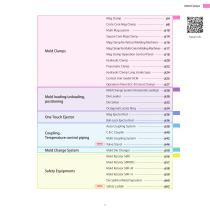

Mold Clamps Mag Clamp …………………………………… p4 Circle Core Mag Clamp ……………………… p8 Multi Mag system Square Core Mag Clamp ……………………… p14 Mag Clamp for Vertical Molding Machines…… p16 Mag Clamp for Multi-Color Molding Machines … p17 Mold Clamps Mag Clamp Operation Control Panel ……… p18 Hydraulic Clamp ……………………………… p20 Pneumatic Clamp …………………………… p22 Hydraulic Clamp Long stroke type ………… p24 Control Unit model HCM …………………… p25 Operation Panel ELC-B (Smart Clamp) ……… p27 Mold Change System (Horizontal Loading) … p28 Die Leveler …………………………………… p30 Mold loading/unloading, positioning Die Setter...

Open the catalog to page 3

Mold Clamps Mag Clamp Powerful permanent magnets(neodymium and alnico) clamp molds instantly. Pascal MAG CLAMP(Magnet clamp) is a mold clamping system for injection molding machines that clamps and absorbs molds using a powerful magnetic force.

Open the catalog to page 4

Mold Clamps Mold fall protection hook t cemen Displa e st m ion sy detect rd standa Displacement detection core Magnet core Mold Displacement Detection System PAT. When the mold moves The electromagnetic coil incorporated in the magnetic core near the center of the clamping plate detects any displacement or floating of the mold (When the mold moves, the induced current generated in the electromagnetic coil is detected as a signal).Pascal Mag clamp is less affected by caps, bolts, holes, and grooves on the mold plate, so it can reliably detect mold displacement and floating. ① Displacement or...

Open the catalog to page 5

Mold Clamps Vertical mold loading Not necessary to standardize mold plate size. (However, the clamping force of the mold depends on the size of the mold plate) Since the space for automatic clamp or mold mounting screws is not required, flexibility in mold design increases; enabling maximize the machine platen area. Automatic clamps require mounting space on the machine platen. Space Mag clamp allows greater flexibility in mold design. Automatic clamp

Open the catalog to page 6

Mold Clamps Horizontal mold loading Even when mold height is not standardized, horizontal mold loading is possible Mag clamps can be used for both simply by adjusting the mold transfering level. vertical and horizontal mold loading Magnet Not necessary to remanufacture the mold plate. Only additional spacers are required for horizontal mold loading. Spacer

Open the catalog to page 7

Mold Clamps Circle Core Mag Clamp Low-cost model "Slim" type is added in product lineup. In addition to the conventional standard shape of the clamp , a new "Slim" model with a simplified plate shape has been introduced to reduce costs. t cemen Displa stem ion sy detect rd standa Displacement detection core Magnet core 3,500kN(350ton)machine: Vertical loading Circle core mag clam

Open the catalog to page 8

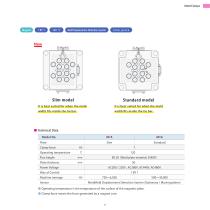

Mold Clamps Mold Displacement Detection System Slim plate Slim model Standard model It is best suited for when the mold It is best suited for when the mold ■ Technical Data Model No. Plate Clamp force Operating temperature Flux height Plate thickness Power Voltage Machine tonnage Sensor MoldMold Displacement Detection System(Stationary / Moving platen) ● Operating temperature is the temperature of the surface of the magnetic plate. ● Clamp force means the force gener

Open the catalog to page 9

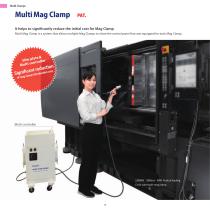

Mold Clamps It helps to significantly reduce the initial cost for Mag Clamp Multi Mag Clamp is a system that allows multiple Mag Clamps to share the control panel that was equipped for each Mag Clamp. late& Slim p roller cont Multi ion reducnt cost t n a c fi Signi mp introductio cla of mag Multi controller 2,800kN(280ton)IMM Vertical loading Circle core multi-mag cl

Open the catalog to page 10

Mold Clamps Proximity Switch Slim plate Each Mag Clamp is equipped with a operation/control panel. Multi Controller for multiple Mag Clamps Clamp plate Operation Control panel box Cost n tio Reduc 1,500kN IMM Clamp plate Clamp plate Multi controller Operation Control panel box Clamp plate Clamp plate Operation Control panel box 11

Open the catalog to page 11

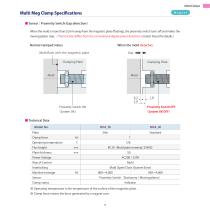

Mold Clamps Multi Mag Clamp Specifications ■ Multi Mag system System Constitution Indicator Proximity Switch (2pieces) Multi Controller Multi Mag system Clamping Plate Slim / Standard See → page 8 This is a cart-type operation panel that can be shared Clamp status(ON or OFF) is indicated mechanically by multiple mag clamps. Move it to the mag clamp and perform clamping/unclamping operations. When clamp

Open the catalog to page 12

Mold Clamps Multi Mag Clamp Specifications ■ Sensor:Proximity Switch ( Gap detection ) When the mold is more than 0.2mm away from the magnetic plate (floating), the proximity switch turns off and makes the moving platen stop.( The function differs from the conventional displacement detection. Contact Pascal for details.) Normal clamped status When the mold detaches Mold flush with the magnetic plate Clamping Plate Clamping Plate ■ Technical Data Model No. Plate Clamp force Operating temperature Flux height Plate thickness Power Voltage Interlocking Machine tonnage Sensor Mold Open/Close (System...

Open the catalog to page 13All Pascal Engineering Inc. catalogs and technical brochures

-

Pascal auto coupler

60 Pages

-

Mold clamping system

136 Pages

-

Press machine system

48 Pages

-

Stamping die clamping system

254 Pages

-

Pascal N2 gas springs

28 Pages

-

mini Gas springs

40 Pages

-

N2 gas springs

86 Pages

-

Pascal Products Introductions

76 Pages

-

Expansion clamp

142 Pages

-

air Work clamping system

130 Pages

-

35MPa Work clamping system

177 Pages

-

Pal system

106 Pages

-

7MPa Work clamping system

256 Pages

-

Pascal mag clamp

72 Pages