Website:

Parker Industrial Gas Filtration and Generation Di

Website:

Parker Industrial Gas Filtration and Generation Di

Group: Parker

Catalog excerpts

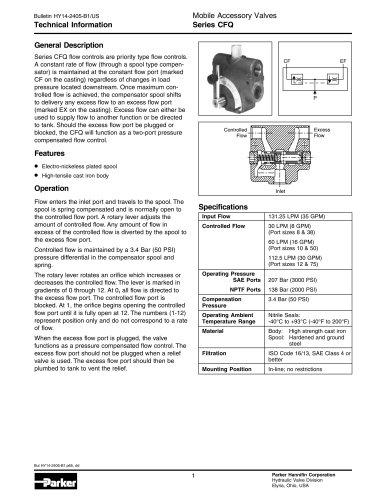

e Solution Two-stage ltration of the feed gas prior to entering the compressor station will eliminate any solids and liquids that could otherwise contribute to compressor failure. A coalescing lter should be used after compression to eliminate compressor lube oil prior to the gas being introduced into the rest of the factory. Compressor and burner foulingՕ Instrument wear Frequent maintenance and repair e Problem In general, pipeline natural gas does not receive adequate ltration prior to entering a factory for use as fuel gas. is gas can contain solids such as sand, clay and iron;...

Open the catalog to page 5

e Solution Filtration of collected land ll gas entering into the compressor will eliminate particles, liquid slugs and aerosols that could otherwise damage downstream equipment. A coalescer should be placed downstream of the heat exchanger to collect any compressor lube oil and condensed liquids. e Problem Land lls are naturally dirty and retain particulate and moisture. Temperature changes increase the amount of condensate at both the heat exchanger outlet and gas collection point. Inadequate ltration of produced gas will lead to: System compressor damageՕ Heat exchanger fouling Unpleasant...

Open the catalog to page 6

Compressor fouling Օ Vehicle fuel system repair Liquids in storage tanks Օ Gas dispenser replacement e Problem CNG is prone to the same types of contamination that is present in traditional fuels solids that collect during handling, water that condenses in tanks and compressor lube oils that carry over into the CNG stream. During its transport to the dispenser, the CNG will also have contaminants that are generated within the delivery system. is leads to: e Solution Installing a lower pressure particulate lter before the compressor station will remove pipe scale to prevent compressor...

Open the catalog to page 7

Pressures to 350 barՕ Coalescing, particulate and adsorption elements available Connections to DN200 Օ Flows from 1429 Nm > Parker o ers an array of lters sized to handle natural gas ows to 228, 204 Nm > 3 / hr and several media choices to meet natural gas application demands. PED compliant lter housings are constructed from carbon steel or stainless steel. Choices of lter media types include glass bre for coalescing liquids, cellulose for particulate removal and activated carbon materials for oil vapour and hydrocarbon removal. Filter element ratings are available from 100 micron down to...

Open the catalog to page 8

With an annual turnover of over $10 billion and 59,000 employees Parker measures its success by what it does for you. Guided by a relentless drive to improve your products and processes, we bring our engineering know-how to your application, wherever it may be.From 60 sales o ces in 44 counties around the world Parker services 8,600 distributors and 1,500,000 customers. > Parker knows that no two construction projects are the same, but we also understand that owners, engineering houses and contractors face similar issues around the world.By involving us at the earliest possible stage of...

Open the catalog to page 10

Parker has been designing and developing engineering-led solutions for over 40 years. Today, having grown with the natural gas market, we continue to provide complete technical solutions for a broad spectrum of companies, from super majors to smaller independents.While we are passionate about engineering, we know how important our customers' service and commercial needs are to them. ats why, whoever you are, from the smallest to the largest, and wherever you operate, you are assured prompt service as well as technical, commercial and logistical solutions that are second to none.Whatever...

Open the catalog to page 11

Austria, Wiener Neustadt phone +43 2622 235010 fax +43 2622 66212 Belgium, Nivelles phone +32 67 280900 fax +32 67 280 999 Czech Republic, Klecany phone +420 284 083 111 fax +420 284 083 112 Denmark, Ballerup phone +45 43 560400 fax +45 43 733107 Finland, Vantaa phone +358 (0) 20 753 2500 fax +358 (0)20 753 2501 > December 2007 / S3.2.231 Parker Hannifi n (UK) Ltd Hermitage Court Hermitage Lane Maidstone, Kent UK phone +44 (0) 1622 723300 fax +44 (0) 1622 728703 www.parker.com Filtration and Separation > Your Local Authorized Parker Distributor size="-1">

Open the catalog to page 12All Parker Industrial Gas Filtration and Generation Di catalogs and technical brochures

-

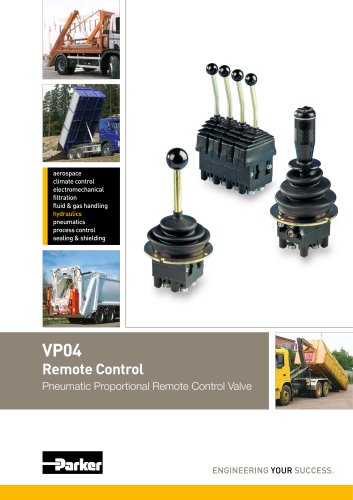

HY17-8356-UK_VP04

12 Pages

-

HY17-8542-UK_QDS6

8 Pages

-

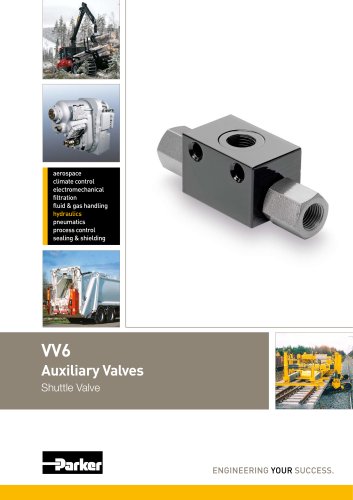

HY17-8602-UK_VV6

8 Pages

-

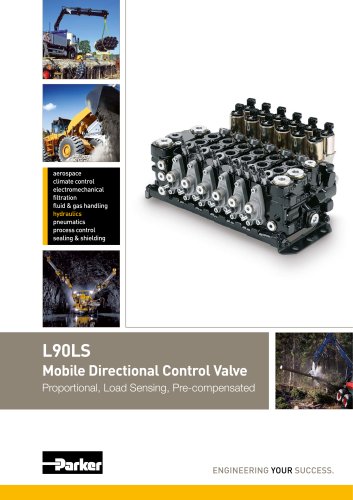

HY17-8504-UK_L90

44 Pages

-

HY17-8557-UK_K170

24 Pages

-

Y14

2 Pages

-

HY17-8702-UK_PLC

12 Pages

-

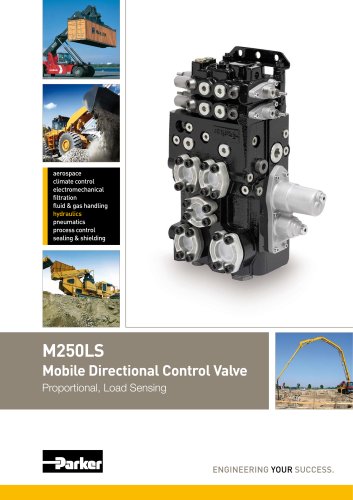

HY17-8562-UK_M250LS

24 Pages

-

7-EN%205150-B%20-%20CAR.

15 Pages

-

Cover

2 Pages

-

HY14-3000FrtCvr

2 Pages

-

HY17-8534-UK_F130

32 Pages

-

20Lo-Torq

2 Pages