Catalog excerpts

Parker Electromechanical & Drives Division - Rohnert Park, CA ! WARNING - USER RESPONSIBILITY FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE. This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigation by users having technical expertise. The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and...

Open the catalog to page 2

Technical Specifications Mechanical Overview Electrical Characteristics Programming software tools for all drives External Stack Controller

Open the catalog to page 3

Parker Hannifin The global leader in motion and control technologies and systems Global Partnerships Global Support Electromechanical Technologies for High Dynamic Performance and Precision Motion Parker is committed to helping make our customers more productive and more profitable through our global offering of motion and control products and systems. In an increasingly competitive global economy, we seek to develop customer relationships as technology partnerships. Working closely with our customers, we can ensure the best selection of technologies to suit the needs of our customers’...

Open the catalog to page 4

DC Drives - DC590+ Integrator Series Up to1600 HP at 700VDC Up to 1250 HP at 500VDC Common programming, set-up and communications platform with AC690+ AC Integrator Series Ratings up to 1950 Amps and supply voltages to 690V, non-regenerative and regenerative models Built-in field regulator Function block programming, including open and closed-loop winder control as standard DRV style includes built-in contactor, fuses and provision for on-board control transformer Interface Options The DC590+ has options to accept most common feedback devices. Armature voltage feedback is standard Building...

Open the catalog to page 5

DC Drives - DC590+ Integrator Series Features and Benefits Rapid Commissioning, optimal control performance and easy maintenance Easy to use operator controls • Detailed diagnostics • Multi-language display With its self-tuning algorithm, the DC590+ can be configured and commissioned within minutes, without turning the motor and without the need for high levels of engineering know how. The operator interface allows easy monitoring of machine operation and simplifies maintenance. Advanced autotuning Standard open fieldbuses Easy integration into existing control networks The DC590+ has a...

Open the catalog to page 6

DC Drives - DC590+ Integrator Series DRV Version -To 500 HP The DRV is a ready to install version of the DC590+ DC Drive. The DC590+ is available in either module, or alternatively “DRV” format up to 500 HP. (15 - 815 Amps / 7.5 - 500 HP at 500 VDC) The DRV includes all the peripheral power components associated with a DC drive system integrally fitted within the footprint of the drive. DRV options include the following integrally mounted within the drive: • AC line contactor standard on all frames. DC contactor available on frames 3 and 4. • AC line fuses • DC fuse (On regenerative...

Open the catalog to page 7

DC Drives - DC590+ Integrator Series Technical Specifications Specifications Power configuration 955+8Rxxx - 4 quadrant regenerative; 2 fully controlled 3 phase SCR bridges, DRV style 955+8Nxxx - 2 quadrant; 1 fully controlled 3 phase SCR bridge, DRV style DC590+ - 4 quadrant regenerative; 2 fully controlled 3 phase SCR bridges, chassis style DC591+ - 2 quadrant; 1 fully controlled 3 phase thyristor bridge, chassis style Armature current rating (Amps DC) Frame Frame Frame Frame Frame Frame Frame Frame Frame Operating Environment Operating temperature Up to 1640 ft (500m) above sea level...

Open the catalog to page 8

DC Drives - DC590+ Integrator Series Technical Specifications Protection High Energy MOV’s Heatsink Overtemperature Instantaneous Overcurrent SCR (thyristor) Trigger Failure Inverse Time Overcurrent Interline Snubber Network Field Failure Zero Speed Detection Speed Feedback Failure Stall Protection Motor Overtemperature Dimensions (in/mm) Inputs/Outputs Analog inputs (5 Total - 12 bit plus sign) 1 - Speed demand setpoint (-10/0/+10V) 4 - Configurable Analog outputs (9 Total - 24V, max 15mA) 1 - Program stop 1 - Coast stop 1 - External stop 1 - Start/Run 5 - Configurable Thermistor Input...

Open the catalog to page 9

DC Drives - DC590+ Integrator Series Overview of Frames 1 and 2 (DRV) Main drive assembly Terminal cover Terminal cover retaining screws Blank cover COMMS technology box (optional) Speed feedback technology card (optional) Gland plate Power terminal shield Power terminals Control terminals Grounding points Keypad port Auxiliary power, external contactor and isolated thermistor terminals

Open the catalog to page 10

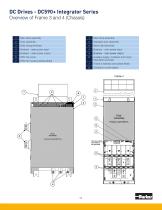

DC Drives - DC590+ Integrator Series Overview of Frame 3 and 4 (Chassis) Main drive assembly Main drive assembly Door assembly Standard door assembly Field wiring terminals Motor field terminals Busbars - main power input Busbars - main power input Busbars - main power output Busbars - main power output IP20 Fan housing (where fitted) Auxiliary supply, contactor and motor thermistor terminals Frame 4 external vent (where fitted) Contactor control select

Open the catalog to page 11

DC Drives - DC590+ Integrator Series Overview of Frame 6 (Chassis) Control panel assembly Front cover Standard door assembly Field controller Busbars - main power input Busbars - main power output

Open the catalog to page 12

DC Drives - DC590+ Integrator Series Electrical Characteristics Part Number

Open the catalog to page 13

Operator Interface and Feedback Standard operator keypad Part Number Standard Keypad Multilingual English · French · German · Italian · Portuguese · Swedish · Polish Quick setup menu Intuitive menus allowing easy and quick setup of the drive Auto-tuning Automatic tuning of motor parameters ensures maximum dynamic motor performance Diagnostics messages Display input and output parameters as well as drive operating units Drive configuration Remote Mounting Kit - Optional The optional keypad mounting kit includes bezel and lead Part Number • Local motor control: start, speed, direction,...

Open the catalog to page 14All Parker Electromechanical and Drives Division Europ catalogs and technical brochures

-

AC15 Variable Speed Drive

16 Pages

-

Belt Driven

32 Pages

-

SensoNODETM

2 Pages

-

Medical solutions

2 Pages

-

RS and AXEM Series

14 Pages

-

DC590P

28 Pages

-

AC890

25 Pages

-

HPLA Linear Actuators

40 Pages

-

AC10 Variable Speed Drive

26 Pages

-

AC30 Variable Speed Drive

42 Pages

-

Parker Automation Controller

20 Pages

-

Explosion Proof Servo Motors

44 Pages

-

Parker Gearboxes

36 Pages

-

GVI Global Vehicle Inverter

16 Pages

-

RTS, RS, RX and AXEM Series

24 Pages

-

TMW Series Torque Motors

32 Pages

-

PSD1 Parker Servo Drive

16 Pages

-

ETH Electro Cylinder_2019

60 Pages

-

Torque Motors – Kit version

111 Pages

-

Frameless Servo Motors

44 Pages

-

HKW Series

133 Pages

-

GVM Global Vehicle Motor

24 Pages

-

PSD1 Parker Servo Drive

12 Pages

-

Belt Driven Positioners

151 Pages

-

PS / RS Series

16 Pages

-

PTN Planetary Gearbox

4 Pages

-

PE Series

12 Pages

-

Motion Solutions

16 Pages

-

ETHERNET Powerlink

20 Pages

-

SMB Motors

28 Pages

Archived catalogs

-

ETH Electro Cylinder_2012

56 Pages