Website:

PARAGON MACHINERY CO., LTD.

Website:

PARAGON MACHINERY CO., LTD.

Catalog excerpts

• Economical Series e-mail: info@paragoncnc.com Economical Series ID/OD Twin-Spindle Grinding Machines

Open the catalog to page 1

INTERNAL GRINDING MACHINES Flawlessly Designed for the Most Meticulous Machining Operations PARAGON reaches new dimensions with the latest generation of CNC internal grinding machines. The Internal Grinding machine has efficient and reliable programming of grinding and dressing cycles suitable for mass production of shaft, rods .bushing and cylindrical workpieces with precise concentricity on inner diameters. The other • Nimble and precise positioning wheelhead • Multi- function and manual adjustable workhead • Highly rigid machine base with hydrostatic lubrication on guideways on Zaxis. •...

Open the catalog to page 2

Unparalleled Quality Assurance and Control The systematic development, production and assembly are carried out in a process oriented manner and in strict compliance with ISO 9001 directives. PARAGON'S Q.C. staff conducts rigorous quality control throughout the entire manufacturing process before shipment. Our quality control process includes: a) Strict Incoming Materials Inspection; b) Geometric Accuracy Inspection; c) Spindle Test and d) Practica Grinding Test. Quality Assurance Over and Over Again, PARAGON'S Dedication to Quality Wins Customer's Satisfaction and Trust. In order to produce...

Open the catalog to page 3

MACHINE BASE New Structural Design Concepts Wheelhead Guideways The table moticn (CNC series).driven by servo motor, features with high rigidity and durability to extend service I ife. C1 class ballscrews feature automatic lubricator, low friction coefficiency, rigidity and high positioning accuracy, providing minimum feeding accuracy Guideways (Z-axis) Extra wide V guideways on base combined with great span in between and constant hydraulic lubrication, exhibit outstanding stability during grinding operation and micro-feed accuracy. The table motion (CNC series) is driven by servo motor...

Open the catalog to page 4

♦ Dialogue type interface, the latest graphic control and digital control technology. ♦ Self diagnostic function for trouble shooting. ♦ Automatic memory while power failure. ♦ Memory function of infeed and dressing compensation. ♦ Multi-dressing can be set up during grinding. ♦ Dressing compensation can be adjusted on-line. ECONOMICAL SERIES ♦ Hydraulic driven automatic wheel infeed. ♦ Hydraulic lubrication features low friction coefficiency, and is pretensioned for increased rigidity and high positioning accuracy. ♦ Tapered roller bearing in wheelhead handles both axial and radial loads...

Open the catalog to page 5

Versatile, Multi-face Machining RTG-100CNC permits various grinding types Maximum 8 faces to be accomplished in one cycle. FANUC Controller Diamond Roller Dresser Exceptional Rigid Base Built for Stability! • Extra fine craftsmanship of scraping on both sides guarantees high accuracy and maximum durability for axes movements. • Powerful FANUC servo ABS system with auto, memory and ffis strong with high efficiency servomotor directly drives ball screw for high feeding accuracy. • The grinding wheel dressing feed is driven by FANUC high precision servomotor for added positioning accuracy. •...

Open the catalog to page 6

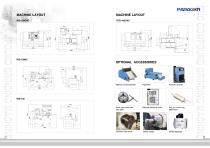

MACHINE LAYOUT MACHINE LAYOUT OPTIONAL ACCESSORIES Magnetic coolant separator Paper filter Scroll 3-jaw chuck with back plate Electrical cabinet air cooler Soft jaw machining Rotary cylinder

Open the catalog to page 7

Inverter (Workhead) Inverter (Z-axis, Wheelhead) Inverter (Y-axis, Wheelhead) Linear Scale for X-axis Linear Scale for Z-axis Coolant Tank with Pump Work Lamp Wheel Flange Extractor (OD G.W.) Paper Filter Magnetic Coolant Separator Automatic Lubricator Electrical Cabinet Air Cooler Automatic Belt Tension Adjustment Unit Electrical Cabinet Heat Exchanger Balancing Stand & Arbor(OD G.W.) Soft Jaw Machining Attachment Servo Moter (Workhead) Servo Motor (X axis) Servo Motor (Y axis) Servo Motor (Z axis)_ Hydraulic Dresser Holder Fixed type Dresser Holder Vibration Meter Grinding Wheel(OD)...

Open the catalog to page 8Archived catalogs

-

Centerless Grinder

10 Pages

-

Polygon Grinding Machine

2 Pages