Website:

Panametrics, a Baker Hughes business

Website:

Panametrics, a Baker Hughes business

Group: Baker Hughes

Catalog excerpts

Panametrics ultrasonic flow meter for liquids Applications The PanaFlow Z3 represents the latest generation of Panametrics ultrasonic flow meters. It is a three-path meter designed specifically for dependable, accurate and repeatable flow measurement of process liquids. With a sleek industrial design and ultra-reliable electronics, it provides operators a cost-effective choice when measurement accuracy and reliability are critical. The capabilities of the PanaFlow Z3 make it the right meter for a number of industries and applications, including: • Upstream, midstream and downstream oil and gas Features and benefits No drifting, no periodic calibration required No loss of process control, no downtime, no expense from calibration, and optimization of assets No wasted energy from running a pump or need to purchase a larger size pump Contamination will not affect meter’s measurement (drifting) or cause any damage to meter Bi-directional measurement No loss of process control, no downtime, no expense from calibration, and optimization of assets Field replaceable transducers No risk in measurement, no shutdown costs for transducer maintenance Precision machined flowcell minimizes flow disturbance for better accuracy • Allocation measurement Explosion-proof transducer design More power to transducer at higher voltages, less risk of attenuation in fluid • Transfer lines Full ultrasonic product line Meet more needs with full product portfolio; one source for all ultrasonic liquid flow meters • Pipeline metering Optional SIL certified configuration for safety criticall applications • Petrochemical • Power generation • District energy/HVAC • Water/wastewater • Process control and monitoring • Batching and blending • Cooling water lines • Loading/unloading • Plant utilities • Tank farms • Irrigation • Crude refine

Open the catalog to page 1

Reliable flow measurement is easy on your budget The PanaFlow Z3 is a three-path, wetted ultrasonic flow meter that brings together all of the advantages of ultrasonic technology at a very affordable value. Unlike other flow measurement technologies, the PanaFlow Z3 does not require maintenance since it does not have any obstruction in the flow path that could clog the process line or moving parts to be damaged by the flowing fluid. The PanaFlow Z3 consists of the Panametrics PanaFlow XMT1000 electronics, three pairs of LX transducers, and sensor body. The XMT1000 is our latest ultrasonic...

Open the catalog to page 2

Specifications Operation and performance Process fluid temperature range Fluid types Liquids: acoustically conductive fluids, including most clean liquids, and many liquids with small amounts of entrained solids or gas bubbles. Flow measurement Correlation transit time model *Maximum process temperature is 203°F (95°C) when additional analog input/output options are selected Pressure range Up to maximum allowable flange operating pressure at temperature per ASME B16.5 or EN1092-1 Piping design • ±0.25% of reading for velocities above 1.6 ft/s (0.5 m/s) • ±0.5% of reading for velocities...

Open the catalog to page 3

Specifications Transmitter Optional input/output • One 4 to 20 mA (SIL) isolated output, 600 Ohm maximum load, NAMUR NE43 (required for SIL installation) Powder coated aluminum (copper free) or stainless steel (SS316) conformal coated Classifications US/CAN: Class I, Division 1, Groups B, C, D; Class I, Zone 1, Ex db IIB+H2 T6...150C; IP 66/67 Type 4X SINGLE SEAL ATEX/IECEx: Ex db IIB+H2 T6...150C FISCO outputs Ta = -40°C to +65°C, IP 66/67 Operating: -40°F to 149°F (-40°C to +65°C*) Storage: -40°F to 158°F (-40°C to 70°C) *Maximum ambient temperature is 60°C (140°F when foundation fieldbus...

Open the catalog to page 4

PanaFlow Z3 part number string A Panaflow Z3 liquid ultrasonic flow meter system Panaflow Z2 liquid ultrasonic flow meter system B - Meter body size: 02 24” (600mm) Flowcell (PF10-Z3 only) C - Process flange rating: 1 PN63 EN 1092-1 D - Meter body material: CC SA-995 GR. CD3MWCUN E - Meter body schedule: 040 Schedule STD F - System design: A Asme B31.3, Ped Nace MR0175/MR0103 G - Painting: A No paint (stainless steel only)

Open the catalog to page 5

PanaFlow Z3 part number string A Standard nde documents(MPI/LPI and hydrotest Standard nde documents and PMI on wetted parts I - Tranducer O-ring: V Viton O-ring, petroleum applications Edpm O-ring, water applications J - Electronics mounting: 000L Local mount Remote mount without cable Remote mount 100FT CBL, per EN60079-14 K - Electronics enclosure: AL Stainless steel XMT1000 L - Cable entries: 1 Standard 3/4” NPT customer entry Standard 3/4” NPT with 6x M20 adapters M - Power: AC 12-28 VDC power supply N - Display option: L Local display O - Input/output: 00 No additional input/output -...

Open the catalog to page 6

PanaFlow Z3 part number string A HART 7 with 4 dynamic variables namur NE43 Foundation fieldbus fisco namur NE107 Q - Calibration: 1 2 Points as left with water, calibration (2” to 8” only) 2 Points as left with water at iso/iec 17025 accredited calibration facility 2 Points as left with water at external calibration facility Special calibration R - Hazardous area certification: 1 US/CANADA class 1, division 1, group B, C, D T6 Ta = -40°C to + 65°C IP66/67 type 4X ATEX/IECEx CERT. for Exd IIB T6 Gb IP66 Ta = -40°C to +65°C IP66/67 Z - Specials: 0 (example part number string) Note: other...

Open the catalog to page 7All Panametrics catalogs and technical brochures

-

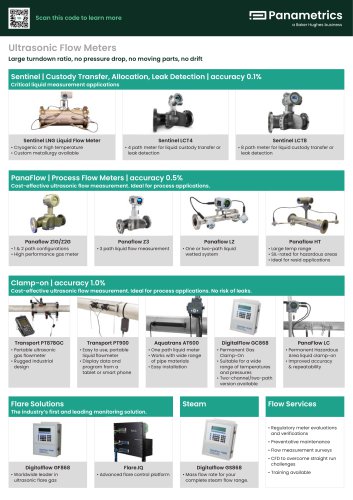

Flow Product Guide

44 Pages

-

PanaFlow LC

8 Pages

-

TransPort® PT900 Datasheet

8 Pages

-

TransPort® PT878GC Datasheet

8 Pages

-

AquaTrans™ AT600 Datasheet

5 Pages

-

DigitalFlow™ GC868 Datasheet

7 Pages

-

DigitalFlow™ DF868 Datasheet

6 Pages

-

PanaFlow™ XMT1000 Datasheet

4 Pages

-

DigitalFlow™ GF868 Datasheet

7 Pages

-

DigitalFlow™ GM868 Datasheet

5 Pages

-

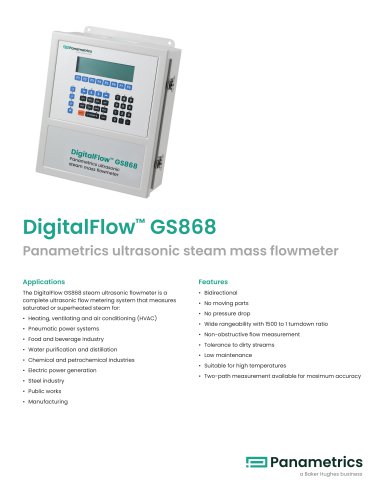

DigitalFlow™ GS868 Datasheet

4 Pages

-

PanaFlow HT Datasheet

8 Pages

-

PanaFlow LZ System Datasheet

5 Pages

-

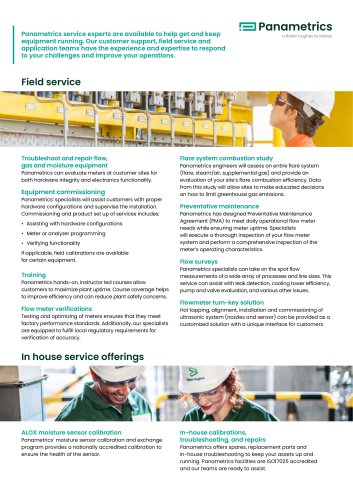

Panametrics Service Catalog

2 Pages