Website:

Panametrics, a Baker Hughes business

Website:

Panametrics, a Baker Hughes business

Group: Baker Hughes

Catalog excerpts

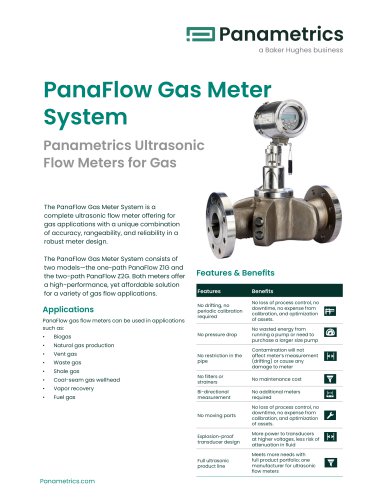

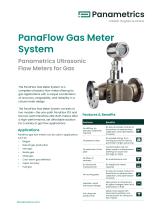

PanaFlow Gas Meter System Panametrics Ultrasonic Flow Meters for Gas The PanaFlow Gas Meter System is a complete ultrasonic flow meter offering for gas applications with a unique combination of accuracy, rangeability, and reliability in a robust meter design. The PanaFlow Gas Meter System consists of two models—the one-path PanaFlow Z1G and the two-path PanaFlow Z2G. Both meters offer a high-performance, yet affordable solution for a variety of gas flow applications. Features & Benefits Features No drifting, no periodic calibration required No loss of process control, no downtime, no expense from calibration, and optimization of assets. No wasted energy from running a pump or need to purchase a larger size pump Contamination will not affect meter’s measurement (drifting) or cause any damage to meter Vapor recovery Bi-directional measurement No additional meters required No loss of process control, no downtime, no expense from calibration, and optimization of assets. Explosion-proof transducer design More power to transducers at higher voltages, less risk of attenuation in fluid Full ultrasonic product line Meets more needs with full product portfolio; one manufacturer for ultrasonic flow meters PanaFlow gas flow meters can be used in applications such as:

Open the catalog to page 1

Reliable Flow Measurement that is Easy on Your Budget The PanaFlow gas portfolio represents a new generation of Panametrics ultrasonic flow meters. Offered in one-path or two-path wetted versions, PanaFlow gas meters bring together Panametrics ultrasonic expertise with the benefits of ultrasonic technology for affordable, high performance flow measurement. Unlike other flow measurement technologies, the PanaFlow meters do not require maintenance since they do not have any obstruction in the flow path to clog the process line or moving parts to be damaged by flowing gas. They provide years...

Open the catalog to page 2

Fast and Easy Installation Proven Technology with Improved Sound Isolation An integrated PanaFlow Gas Meter System is fast and easy to install as all components are already installed in the meter body. The system is factory assembled and tested so it meets strict quality control standards. A PanaFlow meter body is composed of a length of pipe with flanged ends and transducer ports rated to the application’s pressure requirements, so all the user needs to do is bolt the end flanges into place in the process pipeline. A PanaFlow Gas Meter System employs similar robust and reliable transducer...

Open the catalog to page 3

Operation and Performance Fluid Types Acoustically conductive gases Flow Measurement Correlation Transit-Time Meter Body Materials Low temperature carbon steel, SA352 Gr. LCC Stainless steel, SA351 Gr. CF8M Duplex stainless steel, SA995 Gr. CD3MWCuN Flange Ratings Keypad Built-in infrared, six-button keypad for full functionality operation Power Consumption 20 W maximum Process Temperature Range –40 to 302°F (–40 to 150°C) Note: -40 to 257°F (-40 to 125°C) range when used with pressure and temperature sensor option. Ambient Temperature Range Meter Body Certifications PED Cat III, Module...

Open the catalog to page 4

Weights and Dimensions Example Dimensions - 3” [80 mm] Flowcell (see below) Flange Rating Approx. Weight Refer to the table below for weights and dimensions for all line sizes. Reference Drawings Drawing Number Drawing Description General arrangement drawing, PanaFlow ZXG, Local Mount General arrangement drawing, PanaFlow ZXG, Remote Mount “CX” Allow 12.0 [305] minimum recommended maintenance on either side Notes: A 3”-2 Path flowcell is shown as an example. See the drawings listed above for details on other sizes. “CZ” Allow 12.0 [305] minimum recommended maintenance on either side Port...

Open the catalog to page 5

PanaFlow Gas Meter System Part Number AAAA - B - CC PANAFLOW GAS ULTRASONIC FLOW METER SYSTEM B: PATH: Z1G SINGLE PATH METER BODY Z2G DUAL PATH METER BODY C: METER BODY SIZE: 02 2 in. (50 mm) METER BODY 03 3 in. (80 mm) METER BODY 04 4 in. (100 mm) METER BODY 06 6 in. (150 mm) METER BODY 08 8 in. (200 mm) METER BODY 10 10 in. (250 mm) METER BODY 12 12 in. (300 mm) METER BODY 14 14 in. (350 mm) METER BODY 16 16 in. (400 mm) METER BODY D: PROCESS FLANGE RATING: 1 ASME 150# RF (WN) 2 ASME 300# RF (WN) 3 ASME 600# RF (WN) E EN 1092-1/PN 10 (WN/Type 11) F EN 1092-1/PN 16 (WN/Type 11) G EN...

Open the catalog to page 6

PanaFlow Gas Meter System Part Number (cont.) AAAA - O: CABLE ENTRIES: 1 STANDARD 3/4” NPT (FEMALE) 2 M20 (FEMALE) P: CALIBRATION 1 Calibration (Fluid: Air) Q: PREAMP: 00 NO PREAMP 02 2X GAIN PREAMP 10 10X GAIN PREAMP 20 20X GAIN PREAMP 40 40X GAIN PREAMP R: HAZARDOUS AREA CERTIFICATION: 1 US/CANADA CLASS 1, DIVISION 1, GROUP B,C,D T6 Ta = -40°C to + 60°C TYPE4X/IP66 ATEX CERT. FOR Exd IIB T6 Gb 2 IP66 Ta = -40°C to +60°C IECEx CERT. FOR Exd IIB T6 Gb 3 IP66 Ta = -40°C to +60°C Z: SPECIALS: 0 NONE S SPECIAL (EXAMPLE PART NUMBER ST

Open the catalog to page 7

Copyright 2020. Baker Hughes Company. This material contains one or more registered trademark of Baker Hughes Company and its subsidiaries in one or more countries. All third-party product and company names are trademarks of their respective holders.

Open the catalog to page 8All Panametrics catalogs and technical brochures

-

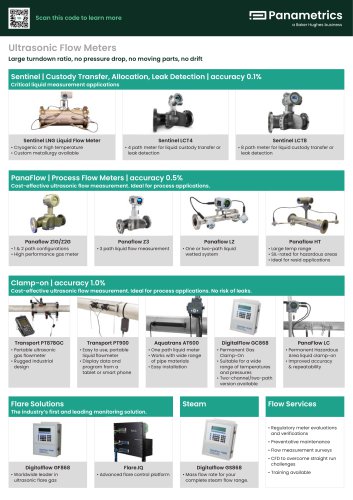

Flow Product Guide

44 Pages

-

PanaFlow LC

8 Pages

-

TransPort® PT900 Datasheet

8 Pages

-

TransPort® PT878GC Datasheet

8 Pages

-

AquaTrans™ AT600 Datasheet

5 Pages

-

DigitalFlow™ GC868 Datasheet

7 Pages

-

DigitalFlow™ DF868 Datasheet

6 Pages

-

PanaFlow™ XMT1000 Datasheet

4 Pages

-

DigitalFlow™ GF868 Datasheet

7 Pages

-

PanaFlow Z3 Datasheet

7 Pages

-

DigitalFlow™ GM868 Datasheet

5 Pages

-

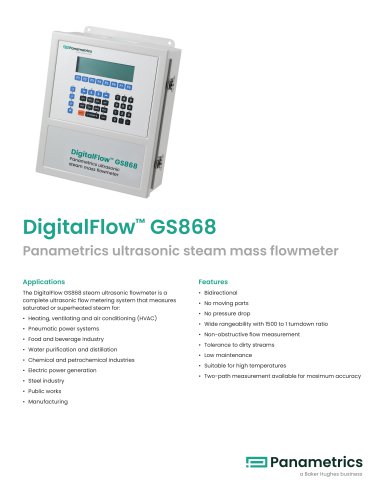

DigitalFlow™ GS868 Datasheet

4 Pages

-

PanaFlow HT Datasheet

8 Pages

-

PanaFlow LZ System Datasheet

5 Pages

-

Panametrics Service Catalog

2 Pages