Website:

Panametrics, a Baker Hughes business

Website:

Panametrics, a Baker Hughes business

Group: Baker Hughes

Catalog excerpts

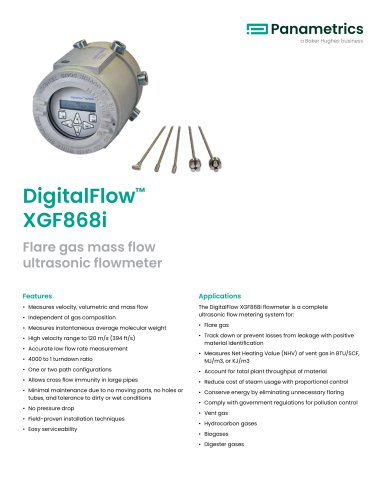

Flare gas mass flow ultrasonic flowmeter Features • Measures velocity, volumetric and mass flow The DigitalFlow XGF868i flowmeter is a complete ultrasonic flow metering system for: • Independent of gas composition • Measures instantaneous average molecular weight • High velocity range to 120 m/s (394 ft/s) • Accurate low flow rate measurement • 4000 to 1 turndown ratio • One or two path configurations • Allows cross flow immunity in large pipes • Minimal maintenance due to no moving parts, no holes or tubes, and tolerance to dirty or wet conditions • No pressure drop • Field-proven installation techniques • Easy serviceability • Flare gas • rack down or prevent losses from leakage with positive T material identification • Measures Net Heating Value (NHV) of vent gas in BTU/SCF, MJ/m3, or KJ/m3 • ccount for total plant throughput of material A • Reduce cost of steam usage with proportional control • onserve energy by eliminating unnecessary flaring C • Comply with government regulations for pollution control • Vent gas • Hydroc

Open the catalog to page 1

Flare gas mass flow meter Best technology for flare gas The DigitalFlow XGF868i ultrasonic flow meter uses the patented Correlation Transit-Time™ technique, digital signal processing, and an accurate method of calculating molecular weight. Add to these features the inherent advantages of ultrasonic flow measurement— reliability with no routine maintenance, high accuracy, fast response, and wide rangeability, the DigitalFlow XGF868i flow meter is the clear choice for flare gas applications. Ultrasonic flow measurement, the ideal technology for flare gas applications, is independent of gas...

Open the catalog to page 2

Ideal for flare gas flow measurement The Correlation Transit-Time technique has distinct advantages over other methods of flare gas flow measurement, and it is used to solve a variety of difficult problems. Typically, gas in flare stacks, headers or laterals is a mixture of components from different sources. Flow rate in flare systems may be unsteady or even bidirectional. Pulsating pressure, varying composition and temperature, harsh environment, and wide flow range further complicate the measurement. The XGF868i is designed for superior performance under these conditions. XGF868i with T17...

Open the catalog to page 3

Designed for flare gas environment The DigitalFlow XGF868i flow meter has no moving parts to clog or wear out. Its patented ultrasonic transducers are constructed of titanium or other metals that withstand the corrosive environment usually found in flare gas applications. The transducers are designed for use in hazardous locations. In contrast to other flow meter types, the ultrasonic transittime technique does not depend on the properties of flare gas and does not require regular maintenance. The DigitalFlow XGF868i flow meter offers a unique combination of rangeability, ease of...

Open the catalog to page 4

XGF868i specifications Operation and performance Fluid types Flare and vent gases Power consumption 20 W maximum Pipe materials All metals, fiberglass. Consult Panametrics for other materials. Flow accuracy (velocity) Dependent on pipe diameter, and gas species. See table below for more information Electronics Flow measurement Patented correlation transit-time mode Storage temperature –67F° to 167°F (–55°C to 75°C) Standard inputs/outputs TTwo 0/4 to 20 mA isolated outputs, 600 Ω max. load Two 4 to 20 mA isolated inputs, 24 VDC loop power, or One 4 to 20 mA isolated inputs, 24 VDC loop...

Open the catalog to page 5

T5/T17 wetted ultrasonic flow transducers Temperature range Normal Temperature (NT): -55°C to 150°C Low Temperature (LT): -220°C to 100°C High Temperature (HT): -50°C to 250°C Extremely High Temperature (XT): -180°C to 300°C Explosion-proof Div. 1, Class I, Group C, D Optional: Group B upon request ATEX II 2 G Ex d IIC T6 IECEx II 2 G Ex d IIC T6 Pressure range Standard: -2 psig to 1500 psig (87.6 to 10300 kPa) Materials • Standard: Titanium • Optional: Monel® or Hastelloy® alloys or SS316 Process connections Flanged and compression fittings Area classifications Explosion-proof Div. 1,...

Open the catalog to page 6

Flow Accuracy Tranducer Type Flow Measurement Range Standard Range Extended Range .1 to 394 ft/s (0.03 to 120 m/s) - non-bidirectional Applicable Pipe Sizes Design Velocity Accuracy from 1 to 394 ft/s (0.3 to 120 m/s) - see notes below Transducer Type T17 Wetted Tranducer Two Paths Calibrated Velocity Accuracy from 1 to 394 ft/s (0.3 to 120 m/s) — see notes below Transducer Type T17 Wetted Tranducer Two Paths Mass Flow Accuracy 2 to 120 kg Molecular Weight Accuracy 2 to 120 kg/kmole +-1.8% to +-2% Net Heating Value (NHV) Accuracy - refer to note 3 Typical accuracy 2% - 5% Flow Velocity...

Open the catalog to page 7

Panametrics, a Baker Hughes business, provides solutions in the toughest applications and environments for moisture, oxygen, liquid and gas flow measurement. Experts in flare management, Panametrics technology also reduces flare emissions and optimizes performance. With a reach that extends across the globe, Panametrics’ critical measurement solutions and flare emissions management are enabling customers to drive efficiency and achieve carbon reduction targets across critical industries including: Oil & Gas; Energy; Healthcare; Water and Wastewater; Chemical Processing; Food & Beverage and...

Open the catalog to page 8All Panametrics catalogs and technical brochures

-

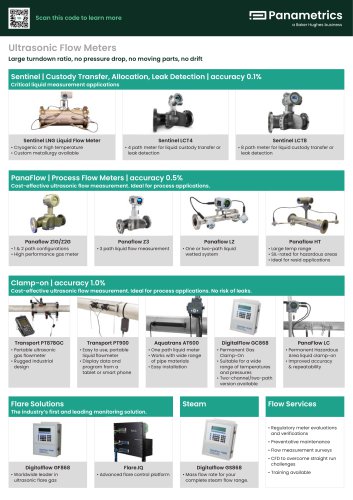

Flow Product Guide

44 Pages

-

PanaFlow LC

8 Pages

-

TransPort® PT900 Datasheet

8 Pages

-

TransPort® PT878GC Datasheet

8 Pages

-

AquaTrans™ AT600 Datasheet

5 Pages

-

DigitalFlow™ GC868 Datasheet

7 Pages

-

DigitalFlow™ DF868 Datasheet

6 Pages

-

PanaFlow™ XMT1000 Datasheet

4 Pages

-

DigitalFlow™ GF868 Datasheet

7 Pages

-

PanaFlow Z3 Datasheet

7 Pages

-

DigitalFlow™ GM868 Datasheet

5 Pages

-

DigitalFlow™ GS868 Datasheet

4 Pages

-

PanaFlow HT Datasheet

8 Pages

-

PanaFlow LZ System Datasheet

5 Pages

-

Panametrics Service Catalog

2 Pages