Website:

Panametrics, a Baker Hughes business

Website:

Panametrics, a Baker Hughes business

Group: Baker Hughes

Catalog excerpts

Panametrics clamp-on gas ultrasonic flowmeter Applications The DigitalFlow GC868 clamp-on gas flowmeter is a complete ultrasonic flow metering system for measurement of most gases, including: • Clamp-on unobstructed installation • Natural gas • Compressed air • Fuel gases • Erosive gases • Corrosive gases • Toxic gases • High-purity gases • Air separation gases • No wetted parts • Two-channel/two-path version available • No moving parts • No pressure drop • Sound speed output • Simple installation • Standard volumetric flow calculation • Supercompressibility compensation • Suitable for a wide

Open the catalog to page 1

The second generation in clamp-on gas ultrasonic flow measurement Historically, clamp-on flow metering was limited to liquids because existing methods could not work on metal pipes containing gases. Several years ago Panametrics developed a new technology that extends all the benefits of clamp-on flow metering to gas measurement. This breakthrough clamp-on gas flowmeter technology has continued to improve, resulting in the second generation of the DigitalFlow GC868 flowmeter. This remarkable ultrasonic flowmeter works with gases at high or low pressure in pipes made of metal and most other...

Open the catalog to page 2

Optional temperature transmitter Downstream transducer Optional pressure transmitter Upstream transducer The DigitalFlow GC868 flowmeter uses the transit-time flow measurement technique The transit-time technique uses a pair of transducers, with each transducer sending and receiving coded ultrasonic signals through the fluid. When the fluid is flowing, signal transit time in the downstream direction is shorter than in the upstream direction; the difference between these transit times is proportional to the flow velocity. The DigitalFlow GC868 measures this time difference and uses...

Open the catalog to page 3

GC868 installation requirements for air, nitrogen, oxygen or argon Pipe size ANSI (DIN) Minimum pressure psig (bar) Maximum velocity, ft/s (m/s) - traverse Single How to use this table. 1. Find pipe size of your application. 2. Find pipe wall thickness of your application. A. etermine if your application meets the minimum pressure requiremen

Open the catalog to page 4

GC868 installation requirements for natural gas Maximum velocity, ft/s (m/s) Pipe size ANSI (DIN) Minimum pressure psig (bar) Single traverse Dual traverse Triple traverse

Open the catalog to page 5

GC868 specifications Operation and performance Fluid types Acoustically conductive gases with minimum density requirements (see Installation requirements table) Flow measurement Correlation transit-time mode Pipe sizes • Most gases: 0.75 to 24 in NB (20 to 600 mm DN) and larger Pipe wall thickness Thicker walled pipes require higher gas density (see installation requirements table) Pipe materials Most metals and plastics. No lined pipes. Flow accuracy (velocity) • For pipes 6 in (150 mm) and smaller: ±2% to 5% of reading typical • For pipes larger than 6 in (150 mm): ±1% to 2% of reading...

Open the catalog to page 6

Optional inputs/outputs There are six additional slots available for any combination of the following I/O boards: • Analog outputs: select up to three additional output boards, each with four isolated 0/4 to 20 mA outputs, 1 kΩ maximum load • Analog inputs: select up to three boards of one of the following types: – nalog input board with two isolated 4 to 20 mA inputs A and 24 V loop power – TD input board with two isolated, three-wire, RTD inputs; R span –100° to 350°C (–148° to 662°F); 100 Ω Pt • Totalizer/frequency outputs: Select up to three totalizer/ frequency output boards, each with...

Open the catalog to page 7All Panametrics catalogs and technical brochures

-

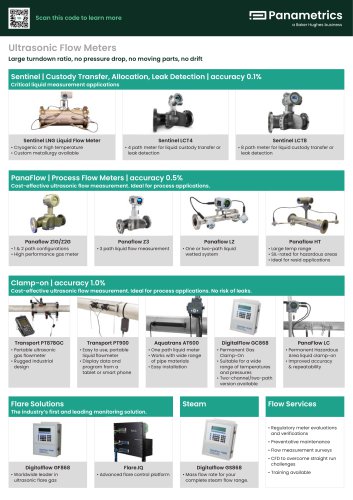

Flow Product Guide

44 Pages

-

PanaFlow LC

8 Pages

-

TransPort® PT900 Datasheet

8 Pages

-

TransPort® PT878GC Datasheet

8 Pages

-

AquaTrans™ AT600 Datasheet

5 Pages

-

DigitalFlow™ DF868 Datasheet

6 Pages

-

PanaFlow™ XMT1000 Datasheet

4 Pages

-

DigitalFlow™ GF868 Datasheet

7 Pages

-

PanaFlow Z3 Datasheet

7 Pages

-

DigitalFlow™ GM868 Datasheet

5 Pages

-

DigitalFlow™ GS868 Datasheet

4 Pages

-

PanaFlow HT Datasheet

8 Pages

-

PanaFlow LZ System Datasheet

5 Pages

-

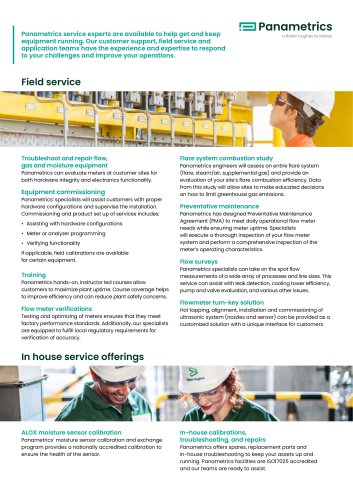

Panametrics Service Catalog

2 Pages