Catalog excerpts

Palamatic Materials Handling Sack Slitting Solutions Palamatic The Palamatic RotaSIit Four easy steps to automatic bag slitting and management: 1. 2. 3. 4. Load the sack into machine. Manual or conveyor fed options available. (A range of Palamatic Vacuum Sack Lifters are available to assist the de-palletising and lifting onto the machine) Sack is opened in the cutting chamber*. The product is discharged efficiently from the cut sacks. *(Auger and rotary blade cutting systems available -dependant on application). Sack cuttings are separated from the product and the screw auger transfers them into the tumble drum chamber where any remaining product is removed. The waste sack is compacted into a dust tight tube for easy disposal.

Open the catalog to page 1

Sack Slitting Solutions Maintenance access hatch Vibrating outlet chute Intgral dust extraction Sack shelf and hinged infeed door Tumble drum chamber with mesh screen Waste sack collecting outlet chute, with hinged access door Primary disc cutting blades Extended machine support frame *Note: Operator access platform not shown Benefits of the RotaSlit High levels of dust containment 镕 Improve overall process cleanliness Controlled material flow Օ Flexibility for on demand throughput capacities Improve plant performance Օ Increase operator performance and safety Customisation to suit...

Open the catalog to page 2

Palamatic Dairy / Food Process ATEX / Hazardous Process *Note: Infeed conveyor not shown Zones 1/21 specification available internally and externally. Minimal internal components reduce product hang-up points. Stainless steel manufacture with range of polished finishes. Typical Materials Handled PE/LDPE Granules Animal Feed Pellets Dicalite Sugar PVC Powder Carbon Black Cement Starch TiO2 Mud Mix Additives Solves capacity, cleanliness, safety and efficiency problems in many Industry sectors such as Chemical, Food, Refractory... Types of Product Handled Cartons/Packets Paper Sacks/Bags Paper...

Open the catalog to page 3

Sack slices tumbled to release remaining product Sack fed through infeed door Sack sliced and/or agitated by cutting system Cobnar Wood Close Chesterfield Trading Estate Chesterfield Derbyshire. S41 9RQ England T: +44 (0)1246 452054 F: +44 (0)1246 451379 E: sales@palamatic.com www.palamatic.com Sack slices compacted in outlet tube Above sketch highlights the path a sack takes once it enters the machine body Case Study Examples Oil/Off-Shore Process Mud mix additive, hopper loading On demand throughput requirements. Typically 4 - 6 sacks/min. Capacity for 8 - 10 sacks/min on demand Paper,...

Open the catalog to page 4All PALAMATIC catalogs and technical brochures

-

Reel Lifting

2 Pages

-

Drum Lifting

2 Pages

-

Vacuum Lifting

3 Pages

-

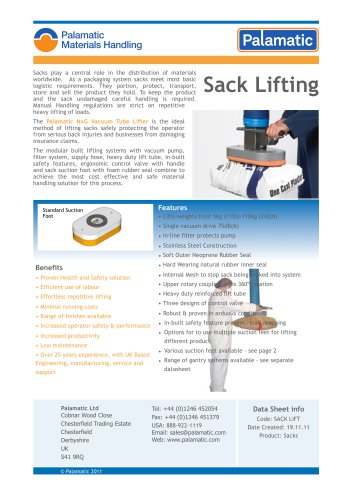

Sack Lifting

2 Pages

-

Palamatic Materials Handling

11 Pages

-

PalPharma Handling Solutions

8 Pages

Archived catalogs

-

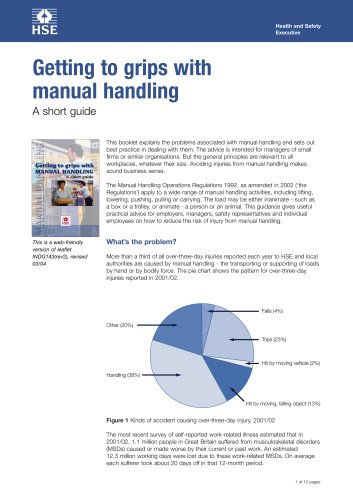

Manual handling guidebook

12 Pages

-

Manual handling guidebook

12 Pages

-

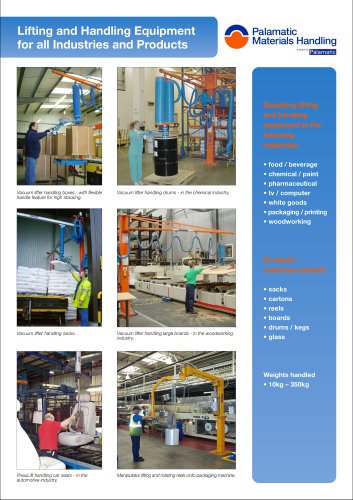

Palamatic Lifting Range

2 Pages