Catalog excerpts

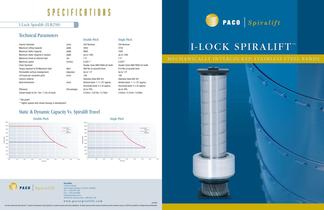

I-Lock Spiralift (ILR250) Technical Parameters PACO Spiralift Double Pitch Single Pitch Column Diameter (mm) 250 Nominal 250 Nominal Maximum Lifting Capacity (daN) 4450 2750 Maximum Static Capacity (daN) 8900 7500 Maximum Static Capacity in tension (daN) Up to 1500 Up to 1500 Maximum travel at reduced load (m) 7.5* 7.5* Maximum speed (m/sec) 0.203 ** 0.203** Chain Sprocket Double chain ANSI RS60-62 teeth Double Chain ANSI RS60-62 teeth Torque required to lift Maximum load (Nm) 980 Nm at sprocket level 610 Nm at sproket level Permissible vertical misalignment (degrees) Up to 1.5° Up to 1.5° Lift travel per revolution pitch (mm) 108 108 Column material Stainless Steel AISI 301 Stainless Steel AISI 301 Band dimensions (mm) Vertical band: 1.1 x 127 approx. Vertical band: 1.1 x 127 approx. Horizontal band: 4 x 34 approx. Horizontal band: 4 x 34 approx. Efficiency (Percentage) Up to 78% Up to 78% Closed height at 3m / 6m / 7.5m of travel 0.545m / 0.674m / 0.738m 0.445m / 0.574m / 0.638m I-LOCK SPIRALIFT TM * See graph ** Higher speeds with closed housing in development Static & Dynamic Capacity Vs. Spiralift Travel Double Pitch Single Pitch 10000 Static capacity ח Lifting capacity z 10000 9000 8000 7000 ^Static Capacity Lifting Capacity -\ \ 4000 0 4000 3000 2000 1000 4,00 5,00 Travel (m) 1,00 2,00 3,00 4,00 5,00 Travel (m) 6,00 7,00 8,00 9,00 PACO Head Office 3185 First Street Spiralift Saint-Hubert (Quשbec) J3Y 8Y6 CANADA Tel.: +1 450 678-7226 Fax: +1 450 678-4060 info@galasystems.com Toll-free (N. America only): 1 800 463-7226 www.pacospiralift.com r r Oct/2009 All marks referenced herein with the symbol are trademarks of Paco Spiralift Inc. its parent company and/or other subsidiaries. All rights reserved. All other marks are trademarks of their respective owners. © 2009 Paco Spiralift Inc. All Rights Reserved Worldwide.

Open the catalog to page 1

HE Principle oi Opration The I-Lock Spiralift ILR250 is a linear actuator that is very compact using two stainless steel bands to form a solid lifting column. The vertical band is stored in a magazine around the ILR250 and the horizontal band is stored below. The vertical band that is perforated is laid over a horizontal band that is toothed with a rotary motion. The horizontal band is raised using a series of cam rollers arranged in a helix pattern. The vertical band is then pushed over the horizontal band. The vertical band is overlapped and the horizontal band perforates the vertical...

Open the catalog to page 2Archived catalogs

-

Precizor lifts

1 Pages

-

Skillet lifts

1 Pages

-

Adjustable Skids

1 Pages

-

AGV Lifts

1 Pages

-

I-Lock 75

1 Pages

-

Complete catalog

26 Pages