Catalog excerpts

Owens Corning and its Composite Solutions Business are dedicated tocreating customer value by delivering world-class products, expertise and support. To this end the company offers the widest range of glass fiber reinforcement products in the world. The business also joins forces with its customers to transform markets from traditional materials to composites.The Composite business at Owens Corning traces its roots to the mid-1930s when company pioneers developed an idea for making continuous glass fibers in commercial quantities. They conducted successful experiments with the process and...

Open the catalog to page 3

Owens Corning's Composite Solutions Business strategy is basedon a simple premise - when our customers grow and prosper, we grow and prosper. And our commitment to your success has never been stronger.You can see that commitment in our product line. We offer theindustry's broadest reinforcement product line, providing unsurpassed design flexibility.You can see that commitment in our people. Our 5,000commercial, operations and technical experts around the world are focused on turning problems into opportunities, and our regional business structure is focused on delivering solutions with...

Open the catalog to page 4

Southern Africa John Mather+27.82.829.3996 > +27.21.762.3067 john.mather@owenscorning.co.za Southern Africa Grant Richardson+27.11.360.8200 > +27.11.813.4414 grant.richardson@owenscorning.co.za >

Open the catalog to page 10

While the core of the reinforcement business at Owens Corning willcontinue to support direct customers with world-class glass reinforcement products, the business also recognizes the need to join with its customers in aggressively promoting the use of composite materials in selected markets. This work is critically important in creating future demand for composite materials and applications.Market and application development work is so deeply ingrained in theglass reinforcements business at Owens Corning that some say the activities are part of the companyҒs DNA. The company and its...

Open the catalog to page 11

Long-Fiber Thermoplastics Җ Traditional injection molding processes forthermoplastic polymers tend to reduce fiber length and limit reinforcement properties. New processes producing materials such as StaMax > Construction Already the largest global market for composite materials,glass fiber reinforcements continue to find new applications in construction replacing wood and other materials. The strength and dimensional stability of Owens Corning reinforcements increase the performance and durability of building materials. The company֒s glass fiber composites also continue to gain importance...

Open the catalog to page 12

InfrastructureMarineSports& RecreationWind Energy Centrifugal casting, filamentwinding, pultrusion and spray-upCold press molding, hand lay-up,infusion molding, RTM, spray-up and vacuum baggingCold press molding, filamentwinding, infusion molding, preforming, pultrusion, RTM and spray-upHand lay-up, infusion molding,preforming, pultrusion, RTM, spray- up and vacuum bagging Multi-end roving, single-end roving,fabrics and veil.Continuous FilamentMat (CFM), Chopped Strand Mat (CSM), fabrics, multi-end roving and veil.Continuous FilamentMat (CFM), Chopped Strand Mat (CSM),single-end roving,...

Open the catalog to page 14

13 ADVANTEX > GLASS FIBER Ζ THE NEW STANDARD > Advantex glass fiber reinforcements from Owens Corning are theinnovative solution to a wide range of customer needs. Conversion to the formula at the companyΒs reinforcement plants now exceeds 80 percent of total capacity.The benefits of Advantex glass fiber begin with a common technologyplatform that is being implemented across Owens Corning product lines and around the globe. It provides customers with a uniform basis for glass fiber specifications offering the same products anywhere in the world.Owens Corning Advantex glass has been...

Open the catalog to page 15

Another pioneering composite solutionfrom Owens Corning is the Silentex > ή noise control system for automotive mufflers and silencers.As roads become more populated, thepressure to reduce noise pollution continues to increase. At the same time,the space automakers are willing to allow for the muffler or silencer is getting smaller. How to control noise more effectively in a smaller space? The solution from Owens Corning is the OC > Silentex noise controlsystem that meets the extensive requirements of muffler manufacturersand automotive OEMs.The Silentex noise control process is an...

Open the catalog to page 16

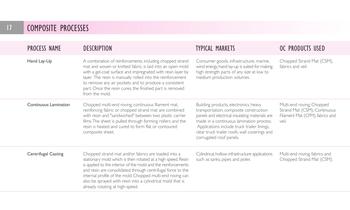

PROCESS NAMEDESCRIPTIONTYPICAL MARKETSOC PRODUCTS USED > Hand Lay-UpContinuous Lamination Centrifugal Casting A combination of reinforcements, including chopped strandmat and woven or knitted fabric, is laid into an open moldwith a gel-coat surface and impregnated with resin layer bylayer. The resin is manually rolled into the reinforcement to remove any air pockets and to produce a consistent part. Once the resin cures, the finished part is removed from the mold.Chopped multi-end roving, continuous filament mat,reinforcing fabric or chopped strand mat are combinedwith resin and...

Open the catalog to page 19

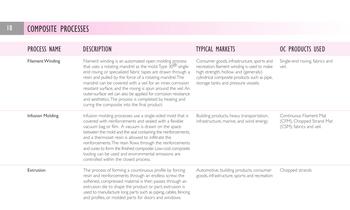

Filament winding is an automated open molding processthat uses a rotating mandrel as the mold. Type 30 single-end roving or specialized fabric tapes are drawn through aresin and pulled by the force of a rotating mandrel. The mandrel can be covered with a veil for an inner, corrosion resistant surface, and the roving is spun around the veil. An outer-surface veil can also be applied for corrosion resistanceand aesthetics. The process is completed by heating andcuring the composite into the final product.Infusion molding processes use a single-sided mold that iscovered with reinforcements and...

Open the catalog to page 20

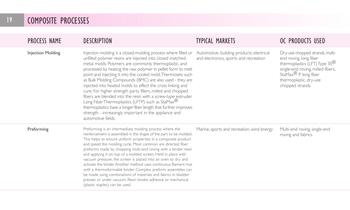

Injection Molding Preforming Injection molding is a closed-molding process where filled orunfilled polymer resins are injected into closed matched- metal molds. Polymers are commonly thermoplastic, and processed by heating the raw polymer in pellet form to melt point and injecting it into the cooled mold. Thermosets suchas Bulk Molding Compounds (BMC) are also used - they areinjected into heated molds to effect the cross linking and cure. For higher strength parts, fillers, milled and chopped fibers are blended into the resin with a screw-type extruder. Long Fiber Thermoplastics (LFTP) such...

Open the catalog to page 21All Owens Corning catalogs and technical brochures

-

Uniconform®

2 Pages

-

Milled fibers REV

2 Pages

-

SingleEnd Roving ST2070

2 Pages

-

AdVeil?

1 Pages

Archived catalogs

-

Innovations for living

12 Pages