Website:

Otto Ganter GmbH & Co. KG

Website:

Otto Ganter GmbH & Co. KG

Catalog excerpts

Telescopic Slides Standard Parts. Ganter.

Open the catalog to page 1

Contents Telescopic Slides General Notes Overview of Types Telescopic Slides with Telescopic Slides with Telescopic Slides with Telescopic Slides with Telescopic Slides with Telescopic Slides with Telescopic Slides with Telescopic Slides with Telescopic Slides with Telescopic Slides with Telescopic Slides with Telescopic Slides with Telescopic Slides with Telescopic Slides with SST Telescopic Slides Mounting Information Technical Information Component Options Fastening Options → Page → Page Partial Extension GN 1400 Partial Extension GN 1404 Full Extension GN 1408 Full Extension GN 1410...

Open the catalog to page 3

Telescopic Slides General Notes General information Telescopic slides offer smooth running, wear-free, and quiet linear motion. They are used in a very wide range of applications. The spectrum ranges from the most simple extensions and drawers to high-quality variants that are used in the industrial environment on machines, production systems, and equipment. The telescopic slides have a multitude of positive features and are still very interesting from an economic standpoint. Here are a few examples of use: sliding doors, protective hoods, keyboards and PC pullouts, vehicle equipment,...

Open the catalog to page 4

Telescopic Slides General Notes Telescopic slides with full extension, back stop position Telescopic slides with full extension, front stop position Highlights - Telescopic Slides |

Open the catalog to page 5

Telescopic Slides Overview of Types Type of extension Load capacity Basic length Material Partial extension T Full extension V Fastening Through-holes Countersunk (Id. no. 1) holes (Id. no. 2) | Highlights - Telescopic Slides Outer slide, through-holes / Inner slide, countersunk holes (Id

Open the catalog to page 6

Telescopic Slides Component Teatures Component features Without With rubber stop rubber stop back-front Latch Locking Locking device back device back, back Type M detach Type E function Type F Latch front Type K Latch back-front Type Q SelfPush to Extension retracting open on both mechanism, mechanism sides dampened / not dampened

Open the catalog to page 7

Telescopic Slides with Partial Extension, Load Capacity up to 280 N A Without rubber stop 3 Identification no. Fastening using through-holes Specification profile Steel, zinc plated, blue passivated Roller bearing steel, hardened • Ball cage Steel, zinc plated lengths and hole spacing attachment options rubber stop locking device (back, front, or back-front) support bracket retraction dampening, external Information Telescopic slides GN 1400 are installed vertically and in pairs. The stroke reaches ≈ 75 % of the nominal length l1 (partial extension). With type A without rubber stop, the end...

Open the catalog to page 8

GN 1400 Telescopic Slides continued Mounting holes - outer slide Mounting holes - inner slide Fastening screws For the said loading forces FS to be absorbed reliably in the surrounding structure, all available through-holes of the outer and inner slide must be used. Failure to use fastening screws reduces the specified load capacity accordingly. The following screws can be used for mounting: Outer slide Inner slide Countersunk screw, Phillips Countersunk screw, Phillips

Open the catalog to page 9

Telescopic Slides with Partial Extension, Load Capacity up to 780 N E With rubber stop, locking device in back 3 Identification no. profile Steel, zinc plated, blue passivated Roller bearing steel, hardened • Ball cage Steel, zinc plated stop Plastic / Elastomer lengths and hole spacing attachment options rubber stop (without locking device) • Other • With Mounting with through holes on external slide and countersunk holes on inner slide support bracket dampening, external | Highlights - Telescopic Slides Information Telescopic slides GN 1404 are installed vertically and in pairs. The...

Open the catalog to page 10

GN 1404 Telescopic Slides continued Mounting holes - outer slide Mounting holes - inner slide Fastening screws For the said loading forces FS to be absorbed reliably in the surrounding structure, all available through-holes and/or countersunk holes of the outer and inner slide must be used. Failure to use fastening screws reduces the specified load capacity accordingly. The following screws can be used for mounting: Outer slide Inner slide Countersunk screw, Phillips Countersunk screw, Phillips Highlights - Telescopic Slides |

Open the catalog to page 11

Telescopic Slides with Full Extension, Load Capacity up to 250 N F With rubber stop, locking device in back, detach function 3 Identification no. Mounting with through holes Specification profile Steel, zinc plated, blue passivated Roller bearing steel, hardened • Ball cage, outer slide Plastic cage, inner slide Steel, zinc plated stop and detach function Plastic / Elastomer The telescopic slides are delivered in pairs. They can be installed on the extension on either the left or right side due to the mechanics. All mounting holes are easy to reach through auxiliary holes. Only the mounting...

Open the catalog to page 12

GN 1408 Telescopic Slides continued Mounting holes - outer slide Mounting holes - inner slide Fastening screws For the said loading forces FS to be absorbed reliably in the surrounding structure, all available through-holes of the outer slide having a diameter (Ø) of 4.2 and of the inner slide having a diameter (Ø) of 4.4 must be used. The elongated holes, Ø 4.2 x 4.4 of the outer slide and Ø 4.4 x 4.6 of the inner slide, are used likewise for fastening and facilitate adjustment during mounting when needed. Failure to use fastening screws reduces the specified load capacity accordingly. The...

Open the catalog to page 13

GN 1408 Telescopic Slides continued Rubber stop, locking device in back The rubber stops of type F dampen the impact of the slide in the respective end position. This feature minimizes noise development and increases the lifespan. Attached to the slides in a partially concealed, partially visible manner, the stops meet each of the requirements in regard to shape, material, and hardness. In the back stop position, the rubber stop takes on additionally a locking function, which is noticeable through a slight resistance on opening and closing. If larger static or dynamic loads occur in the...

Open the catalog to page 14All Otto Ganter GmbH & Co. KG catalogs and technical brochures

-

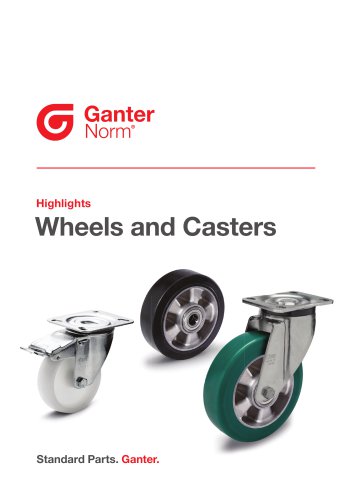

Wheels and Casters

52 Pages

-

Conveyor Components

44 Pages

-

Aluminium Profiles

72 Pages

-

Signal Feedback Included

76 Pages

-

Ganter Catalogue 18.0

2210 Pages

-

Gears and Racks Made of Polyamid

20 Pages

-

Quick Release Couplings

8 Pages

-

Multiple-joint hinges

48 Pages

-

Hygienic Design

32 Pages

-

Couplings

32 Pages