Website:

OTC DAIHEN EUROPE GmbH

Website:

OTC DAIHEN EUROPE GmbH

Group: DAIHEN

Catalog excerpts

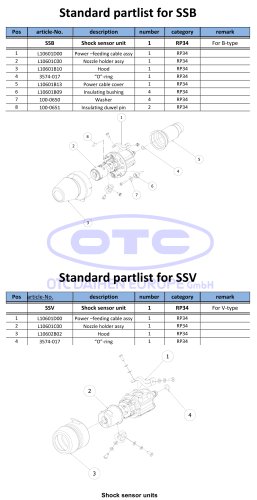

Basic Configuration Number and Part Name i [Ñ] ' Standard C : Welding cable equipment option A1I-V6 ; [J] ' Japanese E : Overseas (English) (MO¿£1:NV61-@|E||F|M) I \¥\ rFlnmnmteil C: Ceiling mounted W : Wall-mounted i [J : Japanese E : English CÏE- terufied U:UL certified W:CMJLcoufied i [V] : NV6, NB4 (type of connected manipulator) ; *** Extension case ; Q] : Japanese E : English U: UL-certified Shock Sensor Torch compatible with built-in shock sensor Shock Sensor Torch Photo: Shock sensor unit SSV mounted. Forced Pressurized Power Feeding Torch Improved welding quality due to stabilized power fed wire. Forced Pressurized Power Feeding Torch for V-type manipulator: Photo: Shock sensor unit SSV mounted. I (MAG rating shown in parentheses) I (HAG rating shown in parentheses) Compact Servo Torch AC servo motor provides stable wire feeding for high-accuracy and high-quality Compact Servo Torch Photo MTXC-3541PS mounted on pull feeder 'The Compact Servo Torch requires the Assist Feeder. In accordance with DAIHEN's policy to make continuing improvements.design and/or specifications are subject to change without notice and without any obligation on the part of manufacturer. This product and the technologies (including software) used in die product are subject to Catch-Ail Controls. When exporting any of them, verify the users, applications, etc. according to CAT.NO.R20801 the applicable laws and regulations and take appropriate procedures such as applications for export permission to the Minister of Economy, Trade and Industry if required. •The information contained in this catalog is current as of August 2008 and is subject to revision without notice. •This catalog was printed with environmentally-friendly soy oil Ink.

Open the catalog to page 1

Improved Manipulator Performance for Shorter Cycle Times Significant increases of the maximum speeds of the individual axes of manipulator allow for even higher productivity than previous models. (Rotation) (Lower arm) (Upper arm) (Swing) (Bending) (Twist) Reliable Arc Start Performance for Absolute Welding Quality The An Series provides a smooth approach to the welding start point, resulting in further improvements of welding quality at the arc start point ©Combine with a Compact Servo Torch for the "Ultimate Arc Start", resulting in even higher welding performance. Welding speed :...

Open the catalog to page 2

Simple & Slim Design Ideal for Arc Welding Challenging the Highest Speeds across the Industry Interference detection sensitivity improved by 40% (from previous model) and control provided for decreasing the interference force, thus reducing collision damage Neat cable layout preventing cable from getting caught during robot operation Through-arm Cable Desip Provides Incredible Welding Performance, Operability and Maintainability for the Ideal Arc Welding Solution. From small to large workpieces, our robots can meet your application needs. Welding large workpieces No need to take into...

Open the catalog to page 3

Versatile Manipulator Robots can now be service for grease while the torch is mounted. Standardized motors between different robot models have been adopted to reduce the number of service parts, The width of the upper arm reduced from interference of arm in narrow spaces. The AII-V6 utilizes a completely sealed structure, preventing droplets in any direction from causing adverse effects. Liner clamping mechanism reduces deviation of wire position caused by changes in the posture of robot A metal jacket has been added to further strengthen the torch body Adaptable to Various Applications...

Open the catalog to page 4

Case Structure features Improved Resistance to Heat and Dustproofing Improved Reliability in Global Environments PC-based management for compatibility with various applications The AX21 controller can be used with a wide variety of applications, including arc welding, spot welding and material handling, addressing all kinds of needs in production processes Controller with Higher Reliability and Maintainability Improved cooling efficiency and dustproofing provides reliable use in severe environments, including production lines with high duty cycles and high-temperature and high-humidity...

Open the catalog to page 5

Manipulator Working Range/Specifications 'The figures below show working ranges of P-point with no torch mounted. Absolute Encoder Absolute Encoder Absolute Encoder Absolute Encoder Note Measured value obtained after sufficient repetition of automatic operation for stabilizing conditions of manipulator operation with upper arm maximum carrying capacity. The value shown in ( ) indicates wall-mounted conditions. When the output flange of the wrist axis is loaded with maximum payload capacity Positional data protected by battery-backed storage inside the manipulator. Working range of J6 axis...

Open the catalog to page 8All OTC DAIHEN EUROPE GmbH catalogs and technical brochures

-

P 402

1 Pages

-

DT-300PII Brochure en

2 Pages

-

T500P Brochure en

1 Pages

-

Leaflet 320 E

1 Pages

-

FD-B4S

4 Pages

-

Leaflet-FD-B6

4 Pages

Archived catalogs

-

YOUR NEW PARTNER FOR WELDING

4 Pages

-

7-Achs-Roboter

4 Pages

-

Druck

1 Pages

-

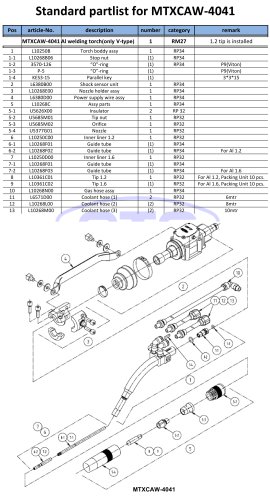

MTXCAW-4041

1 Pages

-

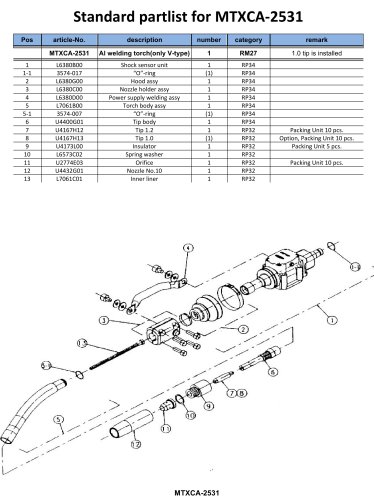

MTXCA-2531

1 Pages

-

Welding & Handling ROBOTS

23 Pages

-

FD-V350

1 Pages

-

FD-V500

1 Pages

-

FD-V700

1 Pages

-

FD-LP130

1 Pages

-

FD-LP180

1 Pages

-

FD-MR20

1 Pages

-

FD-MR35

1 Pages

-

FD-MR50

1 Pages

-

FD-B15

2 Pages

-

FD-V6L

2 Pages

-

FD-V6

2 Pages

-

FD-B4L

2 Pages

-

FD series

28 Pages

-

welbee

10 Pages

-

Specifications MTCAW

1 Pages

-

sensors

1 Pages

-

MIG/MAG Welding Torches

2 Pages

-

Specifications

1 Pages

-

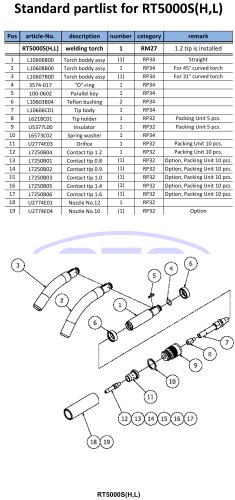

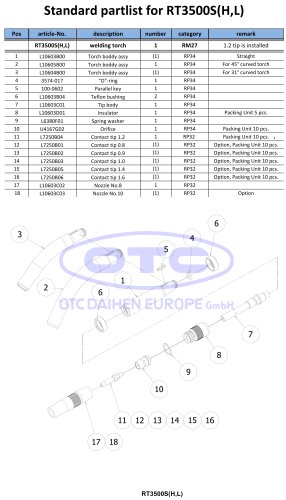

Specifications RT, RZ, RTW

1 Pages

-

Standard partlist for SSB

1 Pages

-

Welding & Handling Robots

28 Pages

-

U.R.I

1 Pages

-

AX-ST

2 Pages

-

AX-C

4 Pages

-

Revotorch

1 Pages

-

Sensor System

8 Pages

-

AII positioner-page1+4

1 Pages

-

AII positioner-page2+3

1 Pages

-

XDM

2 Pages

-

DP-270

1 Pages

-

Compact robots

4 Pages

-

Handling robots

10 Pages

-

Optional Robot Equipment

6 Pages