Catalog excerpts

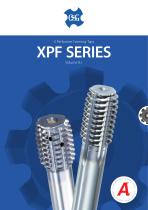

X Performer Forming Taps

Open the catalog to page 1

INDEX Metric A-XPF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-XPF-HB Weldon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Open the catalog to page 2

Metric Fine A-XPF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Open the catalog to page 3

X PERFORMER FORMING (XPF) TAP SERIES 1 Low-torque spec with specially designed threading 2 V-Coating: extreme wear resistance 3 Size range from M1 to M45

Open the catalog to page 4

A-XPF Series S-XPF Series First choice in quality and performance Powder metal forming tap for through & blind holes Multilayer V coating: extreme wear resistance First choice in quality and performance HSSE forming tap for through & blind holes Multilayer V coating: extreme wear resistance High speed tapping in general steels, aluminium, stainless steels For general steels, stainless steels, aluminium

Open the catalog to page 5

XPF IS DIFFERENT FROM OTHERS! Reducing approx. Reducing approx. A thermograph image taken immediately after tapping High Tapping Torque Work Material * To photograph the process, machining was carried out by applying paste instead of using coolant, However, during normal machining, coolant should be used. Restraining Burrs Minimum Quantity Lubrication XPF has a high durability even machining with chlorine-free coolant. S-OIL-XPF is also suitable for MQL machining operation.

Open the catalog to page 6

Deciding cutting speed Does low cutting speed contribute to long tool life? It doesn't apply to XPF. Slow speed tapping, which generates less heat, causes bigger cutting resistance and tool wear. Cutting speed should be adjusted properly to find the most appropriate cutting speed for tool life. Special order products (center through coolant hole) Cutting Speed 2.500 (Holes) 3.000 (Holes) 4.500 (Holes) 4.375 (Holes) 5.000 Excessive Wear Excessive Wear Excessive Wear GP-OUT Excessive Rubbing Noise GP-OUT GP-OUT GP-OUT Choosing the Appropriate Coolant High lubricant water-soluble coolant is...

Open the catalog to page 7

Calculation for torque XPF achieves 30% reduction of torque, according to the calculation. The tapping data on page 3 shows 40% reduction of torque in synergy with appropriate cutting speed. Please refer to the following table for large diameter tapping and the formula for calculating torque. Calculated machining torque of large diameter taps by work materials Conventional forming taps K : Coefficient of work material E : Pitch diameter P : Pitch In case of M30 X 3,5 working on SCM440 T = 0,06864 x 14 x 27,727 x 3,52 = 326 N/m The above formulas are the guidliene in case of the external...

Open the catalog to page 8

Recommending 60° for the chamfer Forming tap forms the screw thread by plastic deformation. Therefore, without having chamfering, burr is made on the edge of the hole. To prevent burr, chamfering with 60° is highly recommended If 118° of chamfering is required for drilling, burr is prevented by setting the diameter of chamfering to screw size + 2 pitches (Example: M10x1,5 ■=> 10mm (1,5x2)=13mm Shape of complete thread and it's differenceThe formed thread has a small slit at the crest. 9

Open the catalog to page 9

Internally-fed coolant improve tool life Tool S-OIL-XPF Competitor External Conventional Product 421 (Holes) 200 (Holes) 1 (Hole) 1 (Hole) ■ Ex. Rubbing Noise Ex.Wear Breakage Excessive Wear Excessive Wear Excessive Wear

Open the catalog to page 11

■ First choice in quality and performance ■ Powder metal forming tap for through & blind holes ■ Multilayer TiCN coating ■ High speed tapping in general steels, aluminium, stainless steels ■ Powder metal for long tool life

Open the catalog to page 12

Threading | Forming taps | Metric First choice in quality and performance Powder metal forming tap for through & blind holes Multilayer TiCN coating High speed tapping in general steels, aluminium, stainless steels Side through coolant

Open the catalog to page 13

S-XPF NEW SIZES Threading | Forming taps | Metric ■ First choice in quality and performance ■ HSSE forming tap for through & blind holes ■ Multilayer TiCN coating ■ For general steels, stainless steels, aluminium

Open the catalog to page 14

Threading | Forming taps | Metric ■ First choice in quality and performance ■ HSSE forming tap for through & blind holes ■ Multilayer TiCN coating ■ For general steels, stainless steels, aluminium ■ Side through coolant

Open the catalog to page 15

■ First choice in quality and performance ■ HSSE forming tap for through & blind holes ■ Multilayer TiCN coating ■ For general steels, stainless steels, aluminium ■ For 6G internal thread tolerance

Open the catalog to page 16

Threading | Forming taps | Metric ■ First choice in quality and performance ■ HSSE forming tap for through & blind holes ■ Multilayer TiCN coating ■ For general steels, stainless steels, aluminium ■ For 6G internal thread tolerance, side through coolant

Open the catalog to page 17

Type 2 ■ First choice in quality and performance ■ HSSE forming tap for through & blind holes ■ Multilayer TiCN coating ■ For general steels, stainless steels, aluminium ■ For 7G internal thread tolerance

Open the catalog to page 18

Threading | Forming taps | Metric Metric Threading | Forming taps

Open the catalog to page 19

Type 2 ■ First choice in quality and performance ■ HSSE forming tap for through holes ■ Multilayer TiCN coating ■ For general steels, stainless steels, aluminium ■ Chamfer Form D

Open the catalog to page 20

Type 2 ■ First choice in quality and performance ■ HSSE forming tap for through & blind holes ■ Multilayer TiCN coating ■ For general steels, stainless steels, aluminium ■ Chamfer Form E Metric Threading | Forming taps 21

Open the catalog to page 21

Threading | Forming taps | Metric Type 2 ■ First choice in quality and performance ■ HSSE forming tap for through & blind holes ■ Multilayer TiCN coating ■ For general steels, stainless steels, aluminium ■ Center through coolant, chamfer Form E

Open the catalog to page 22All OSG catalogs and technical brochures

-

ADO-MICRO

16 Pages

-

S-TAP SERIES

40 Pages

-

ADO-SUS SERIES VOLUME 4.2

20 Pages

-

SOMTA VOL-5.1

64 Pages

-

ADO MICRO

16 Pages

-

ADO 40D 50D

12 Pages

-

CATALOGUE VI

1024 Pages

-

EPL-HP Series

8 Pages

-

Thread Mill Series

24 Pages

-

XPF Series

32 Pages

-

A-TAP Series

52 Pages

-

PSTW Phoenix

8 Pages

-

AE-VMS

8 Pages

-

EX-(SUS)-Series

24 Pages

-

DCT Diameter Correction Tool

8 Pages

-

HY-PRO Milling Series Vol.3

12 Pages

-

HY-PRO Drill Series Vol.3

20 Pages

-

TDXL HSS Drill Series

12 Pages

-

H-TAP H-SFT/H-POT

12 Pages

-

WDO Drill Series

12 Pages

-

ADF Carbide Flat Drills

12 Pages

-

Long-neck & Bull nose end mills

28 Pages

-

VP(O)-DC-MT Tap Series

8 Pages

-

OSG Indexable Series

111 Pages

-

OSG HSS End Mills Catalog

38 Pages

-

OSG Milling Catalog

234 Pages

-

OSG Drills Catalog

148 Pages

-

OSG Taps Catalog

285 Pages

-

Composite Solutions Vol.3

28 Pages

Archived catalogs

-

V-XPM-HT

4 Pages

-

Dental Solutions Vol.5

24 Pages