Catalog excerpts

Immediate Deburring after Machining When safe and cost effective solutions matter

Open the catalog to page 1

From start to finish, Osborn has your back. As the global leader in surface treatment and finishing solutions, Osborn knows that it’s about more than just a product. With Osborn, you have a partner; an expert in your field that is dedicated to providing you the right solutions to do the job at hand better, faster, and safer.

Open the catalog to page 2

Save Cost, Increase Efficiency, Improve Results. Our Advanced Technology Brush System products, or ATB®, are specifically designed for automated deburring. Our experts can assist you in finding the perfect product for your particular application. Contact us today. Content About Osborn Index Advantages Special Features Applications Application Engineering Sample Processing

Open the catalog to page 3

Reduce Cycle Times. Increase Efficiency. Let Osborn and its ATB® line assist you with deburring and edge rounding, quickly, reliably and automatically immediately after machining. ATB® can be used on machining centres, CNC machines and in robotic cells. Our products can be adapted to process any material.

Open the catalog to page 4

That’s why ATB® is a Time Saver: ■ ATB ® is designed for direct adaptation to tool holders (e.g. HSK/SK, combination mandrels, collets, surface chucks). ■ It is is designed to be used on machining centres and CNC machines under the same operating conditions as the cutting tools (e.g. use of cooling lubricants, emulsions, water). ■ You can start the deburring of the components immediately after the upstream machining process, even on the same machining centre / CNC machine. Thanks to its tool holder compatibility, the ATB ® can be stored directly in the tool magazine of the machining centre....

Open the catalog to page 5

Extra long life brushes. Reduce set-up time. Various Mounting Options designed for direct adaptation to different tool holders. These long life brushes reduce set-up time and cost per part. Additionally, the performance of the brushes provide a high level of accuracy and repeatability.

Open the catalog to page 6

Maximum Fill Density Unlike punched brushes, the fill material is firmly cast into the body of the ATB ® brush. There are approximately 4 times more bristles, which significantly increases the service life. Fill Pattern A variety of diameters and fill patterns are possible. The diameters range from 50 mm to 250 mm, whereby abrasive grains such as aluminum oxide, silicon carbide, ceramics and diamond are available in different sizes and various filament lengths. There are also fill density and segment fill options to vary the aggressiveness and brush flexibility. Support Collar An optional...

Open the catalog to page 7

Features and Benefits at a Glance. Resin Cast Body The fill material is firmly cast into the bodies of our ATB ®. Benefit: ATB ® can be run faster while maintaining its fill integrity, highly precise design with a high level of tilting rigidity while remaining lightweight. Maximum Bristle Density A maximum bristle density with up to 4 times more bristles. Benefit: Longer service life, more aggressive brushing action. Even very complex components can be deburred quickly and effectively. High Tech Filaments Nylon threads interspersed with abrasive grit (e.g. silicon carbide or ceramic) are...

Open the catalog to page 8

Many Diameters and Patterns A wide range of diameters are available. In addition, both the fill length and the fill pattern can be individually adapted. Benefit: With our individualized options, we can find you the best solution for your deburring application. An increase in the fill length can, for example, increase the service life and flexibility in order to deburr challenging components. Changing the fill pattern can increase the aggressiveness depending on the need. Dimensionally Stable and Flat The surface of ATB ® is flat. Benefit: Even edge rounding can be achieved, wear...

Open the catalog to page 9

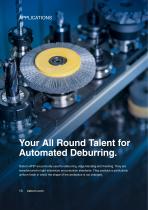

Your All Round Talent for Automated Deburring. Osborn ATB ® are primarily used for deburring, edge blending and finishing. They are manufactured to tight tolerances and precision standards. They produce a particularly uniform finish in which the shape of the workpiece is not changed.

Open the catalog to page 10

Which Components can be Machined with Osborn ATB®? ■ ■ ■ ■ ■ Sheet metal, stamped and fine-blanked parts Precision parts, ground and lapped parts Contour-rich components Drawn, laser-cut or milled parts Parts from forming technologies Typical Applications Examples of typical applications include the deburring of cylinder heads, engine blocks, hydraulic and pneumatic components, valve plates, contact and sealing surfaces and toothed components. Additional information Do you require a more detailed overview on our ATB ® brush portfolio? Download our brochure at: www.osborn.de/en/atb

Open the catalog to page 11

APPLICATION ENGINEERING We Help You to Identify Undetected Potentials. There are many questions concerning the ideal process for deburring. If you find yourself with one of these questions, we would like to help you. ■ ■ ■ ■ ■ ■ ■ Which tool is best suited for my deburring process? I would like to test alternatives to my current tools. Do I still have potential in my machining process? Which parameters can I still work on? How can I reduce the cost-per-part sustainably? The machining results are difficult to reproduce. What can I do? The brushes wear out too quickly and I there is too much...

Open the catalog to page 12

Before Machining Clear burr formation on the edge. Grooves on the surface. After Machining Burrs were reliably removed and the edges rounded. The surface has an even, brushed appearance. We will be happy to advise you! Our application engineers will be happy to look at your application and help you choose the right tool to ensure that cycle time, machining results and cost-per-part are optimized. Get in touch with us today. Phone Email Web

Open the catalog to page 13

SAMPLE PROCESSING What We can Do for You If you are in doubt whether you already have the ideal deburring tool for your machining process, we recommend our sample processing service. This is an excellent opportunity to put the quality of your current deburring tools to the test and, if necessary, replace it with a more suitable tool for the application. With the appropriate fill material, and optimized design, we are confident we can help. Together with you, we determine the ideal tools to be used to process your sample parts. We then agree on the parameters most important to you. On...

Open the catalog to page 14All Osborn GmbH catalogs and technical brochures

-

AS 46 T INOX Freecut

1 Pages

-

CS 24 R

1 Pages

-

AS 36 S IN

1 Pages

-

AS 36 T

1 Pages

-

AS 24 R Bahn

1 Pages

-

IDLER ROLLER & RAIL SOLUTIONS

47 Pages

-

Osborn Roller Technologies

36 Pages

-

Osborn Topseller

15 Pages

-

Osborn Catalog 2020/21

320 Pages

-

TOOLS FOR X-LOCK

24 Pages

-

Cordless Power Tool Accessories

16 Pages

-

Oil- and Gas Industry

48 Pages

-

Osborn Polishing Catalogue

10 Pages

-

Osborn Load Runners

92 Pages

-

Osborn TurbFly (SnowProtec)

7 Pages

-

Osborn Broomate

2 Pages

-

Osborn Woodworking Technology

24 Pages

Archived catalogs

-

Osborn ECO

24 Pages

-

Osborn (USA) Welder's Choice

15 Pages

-

OSBORN EZ-Flex catalogue

2 Pages

-

OSBORN Novofil catalogue

18 Pages

-

OSBORN MultiStrip catalogue

14 Pages

-

OSBORN TOP catalogue

44 Pages