Catalog excerpts

Orkel MP2000 Compactor www.orkel.no English

Open the catalog to page 1

The Orkel MP2000 is world wide the first series-produced round bale combination for organic short fibre products ! A new era hast started. Now it is possible to store, transport, distribute and deal with maize silage and other short fibre products in wrapped round bales. Maize silage in round bales becomes more and more popular No investment in silos, easy handling and the safe feeding quality, as well in the summer months, makes the demand for maize silage in round bales rising very fast. With the Orkel MP2000 it is possible to bale and wrap maize silage quickly and proper in one process....

Open the catalog to page 2

The machine for the professional contractor A tractor is used for both, operating and pulling the MP2000. For driving, the tractor has to be placed sideways and connected with the pto shaft to the machine. The pto shaft operates a hydraulic pump, which delivers oil for the complete hydraulic system of the machine. The MP2000 is constructed for 40 km/h. The breaks are prepared for both hydraulic or air pressure. Fast transportation on the road from one customer to the other is important for the economic use of the MP2000. The customer doesn't earn money when driving on the road!

Open the catalog to page 3

Reliable wrapper technology The bales are wrapped with the proved Agronic double arm wrapper. After sliding on the ground, the bales can be picked up and transported to the storage place. Small losses on the ground The rollers of the baling chamber are covered with two big rubber belts to reduce losses. The material falling out, will be recycled by a continuously going conveyor under the chamber and returned to the elevator. Careful handling of the bales When released from the chamber, the bales drop carefully on the conveyor belt. This moves them onto the wrapper table. After being wrapped...

Open the catalog to page 4

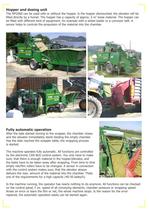

Hopper and dosing unit The MP2000 can be used with or without the hopper. Is the hopper dismounted, the elevator will be filled directly by a funnel. The hopper has a capacity of approx. 6 m3 loose material. The hopper can be filled with different kind of equipment, for example with a wheel loader or a conveyor belt. A sensor helps to controls the propulsion of the material into the chamber. Fully automatic operation After the bale started moving to the wrapper, the chamber closes and the elevator immediately starts feeding the empty chamber. Has the bale reached the wrapper table, the...

Open the catalog to page 5

Fast setting up and taking down down easily and in very short time. This flexibility holds the costs for problem for the contractor to have customers with the demand of only a little number of bales. After the tractor is uncoupled, the draw bar has to be retracted hydraulically. If using the hopper, it has to be lowered hydraulically to working position. With the hydraulic jacks, the machine can be leveld on every ground, f.ex. at the edge of a field. That's very important for the machine to operate satisfactorily. The MP2000 can operate with or without hopper. In cases, were it is required...

Open the catalog to page 6

Reasons/arguments for pressing and wrapping maize silage in round bales Maize silage has all assumptions for high value forage. It combines high energy concentration with high yield, in average 43t/ha (whole plant) and 130 GJ NEL/ha. Moreover, unlike grass, maize is a perfect energy source and also contains starch that helps dairy farmers improve rations. Forage quality Middle-sized livestock farmers have big problems with past fermentation of maize silage in big silos. After many years experience with maize in round bales the conclusion is: - You attain forage of highest quality! - It...

Open the catalog to page 7

Technical data Autom. greasing of bushings Autom. chain lubrication Hydraulic chamber locking Bushings technology Stationary operation Fully automatic CAN BUS control system Doublearm wrapper Electro hydraulic control of all functions Electrostatic drive of the bale chamber Manufacturer reserves the right for changes. - November 2003 Photos of products may show extra equipment. Importer/Dealer: Manufacturer:

Open the catalog to page 8All Orkel catalogs and technical brochures

-

HI-X

9 Pages

-

MP / MC

16 Pages

-

DENS-X

20 Pages

-

Orkel DX 120 dump trailer

12 Pages

-

MC-850

2 Pages

-

MP2000 Industry Baler

8 Pages

-

Orkel Balers

8 Pages