Catalog excerpts

Orkel round balers O www.orkel.no

Open the catalog to page 1

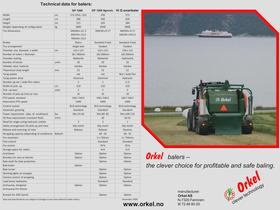

Orkel round balers are developed and manufactured in Norway. The balers are constructed for the roughest and most demanding conditions in baling. A number of baler properties provide important advantages. More forage – in less bales, is increasing the forage quality and reducing wrapping cost. Bushings on rollers have 5 years of warranty, please continue reading…. Orkel GP 1260 Agronic Orkel GP 1260 Orkel hiQ

Open the catalog to page 2

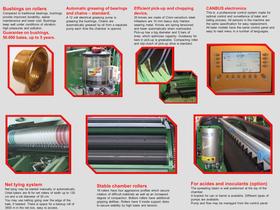

Bushings on rollers Compared to traditional bearings, bushings provide improved durability, easier maintenance and lower cost. Bushings keep well under conditions of vibration, high pressures and pollution. Automatic greasing of bearings and chains – standard. Efficient pick-up and chopping device. A 12 volt electrical greasing pump is greasing the bushings. Chains are automatically greased by oil from a separate pump each time the chamber is opened. 20 knives are made of Crom-vanadium steel. Infeeders are 10 mm heavy duty Hardox wearing metal. Knives are spring tensioned and lower...

Open the catalog to page 3

Orkel GP 1260 - for grasses, hay and straw Orkel GP 1260 -top quality baler, baling top quality bales Forage quality of the bale is of great importance and is managed by the GP 1260. In an hectic harvesting season, drive stability is important as well. In this matter, the GP 1260 keeps its promises. Steady baling, compact bales, is its specialty. Simple and easy to overview Reliable drive Excellent flotation Greasing of chains Automatic greasing of chains. Oil is efficiently distributed by high quality brushes. Bracket for cans Bracket for cans or barrel is available. (option) A functional...

Open the catalog to page 4

Orkel GP 1260 Agronic - simple and safe under all conditions Orkel GP 1260 Agronic: Reliable – efficient and attractiv. High second hand value. A well working baler – wrapper combination, based on high quality components and proven technology. Rational solution – one machine – two jobs Optimal solution – improved economic conditions Well balanced, easy access also by difficult conditions. Properties to be valued: Film holders 4 units on each side as standard. Totally 8 extra film rolls possible to carry. Hydraulic components Hydraulic valves and components are located inside a closed cover...

Open the catalog to page 5

Orkel hiQ smartbaler - Increased bale density – lower cost – higher forage value New technology improves the round baling method. Orkel hiQ smartbaler provides optimal baling results. ACC – “Active chamber control” surveys and adjusts the baler pressure continuously. The system improves bale density by appr. 15 % compared to static and mechanical pressure conditions. BMP – “Bale process monitoring” provides a complete management from the control panel by controlling the chamber pressure, net tying etc. You may also set bale diameter between 120 cm and 130 cm from the panel. High capacity...

Open the catalog to page 6

Orkel HiT (high tension) - wide film and net-system for hi Orkel HiT Q smartbaler system Provides use of net or wide film directly to the bale – your choice. By applying wide film wider than 130 cm, the film will go over the edge of the bale as well. These are the wide film advantages: . Orkel HiT – apply wide film straight to the bale. Pre-stretched wide film increases the pressure in the bale. Wide film replacing net is profitable and future orientated technology. Improved oxygen barrier Impressive bale shape and compaction Higher forage quality Only one type of product , plastic +...

Open the catalog to page 7

Data and specifications are subject to changes at any time without further notice. November 2009

Open the catalog to page 8All Orkel catalogs and technical brochures

-

HI-X

9 Pages

-

MP / MC

16 Pages

-

DENS-X

20 Pages

-

Orkel DX 120 dump trailer

12 Pages

-

MC-850

2 Pages

-

MP2000 Industry Baler

8 Pages

-

Orkel MP 2000 Compactor

8 Pages