Catalog excerpts

EWS PETRO P160 “CLEAN-FRAC” Process and Equipment Description Background Tightening environmental & regulatory standards and escalating capital & operating costs are driving demand for beneficial reuse of process water. OriginOil’s EWS Petro™ P160 is the Electro Water Separation™ (EWS) model that processes 160 liters (one barrel) per minute in frack flowback and produced water cleanup applications. Multiple P160 models can be combined in parallel, or larger EWS Petro models can be installed. As this is a continuous process, throughput is not a limiting factor. EWS Petro removes organic particles and kills bacteria from large volumes of water at considerably lower cost than disposal or competing treatment systems. Function Based on OriginOil’s proprietary EWS technology, EWS Petro is a continuous and chemical-free, low energy process to efficiently remove hydrocarbons, suspended solids, and bacteria from produced or ‘frac flowback’ water. Testing has shown that OriginOil’s EWS Petro system reduces organics, as measured by Chemical Oxygen Demand (COD), by as much as 98% and reduces Total Suspended Solids (TSS) by as much as 99% in a matter of minutes. OriginOil’s EWS Petro system consists of three integrated modules: - Single Step Extraction™ (SSE) tubular reactors designed to break the oil and water emulsion, neutralize surface charges on oil droplets and suspended solids, and agglomerate the particles in the water phase. This module also kills bacteria throughout the process water. OriginOil’s proprietary gas flotation chamber is specifically designed to lift the agglomerated oil and solids to the surface of the water where a Patents Pending This work is licensed under a Creative Commons License

Open the catalog to page 1

rake and dewatering belt separate the floated material from the surface of the water. - Supervisory control and data acquisition (SCADA) system to measure input and output parameters and automatically control the process through proprietary algorithms. Deployment EWS Petro can be used as a standalone system for the separation and recovery of organics from produced or frac flowback water, enabling clients to reuse their process water for further fracturing or flooding operations. Reusing the water significantly reduces trucking and disposal costs, and may soon be required by regulators....

Open the catalog to page 2

Step One: Concentration The OriginOil SSE technology is at the core of EWS Petro system. The system utilizes electromagnetic pulses controlled by proprietary algorithms developed to optimize efficiency. The electromagnetic pulses are used to break oil and water emulsions, kill bacteria, neutralize surface charges on free oil and suspended particles, and enable coagulation of suspended and dissolved organic material. Step Two: Flotation The gas flotation chamber generates a cloud of micro-bubbles to lift oil and coagulated materials to the surface of the water. The mechanical design of the...

Open the catalog to page 3

Engineering Drawing of the EWS PETRO P160 Process Control The SSE Reactors and gas flotation chamber are controlled by a SCADA to monitor the operational parameters and adjusted process variables to match the type of process water being treated. The SCADA system can monitor specific water parameters and make realtime adjustments to control the electromagnetic pulse characteristics for maximum efficiency and minimum energy usage. Key Features - 98% reduction in organics as measured by COD Reduces TSS and color (PtCo CU) by as much as 99% Removal of heavy materials Breaks oil/water emulsion...

Open the catalog to page 4

Configurations All systems are fitted with connections for produced water input, effluent water, hydrocarbon product output, heavies output and external power connection. Unless the system is integrated into an OEM end to end treatment system, client must supply all external pumps, piping, fittings and power external to the system. Production Models The Model P160 (160 liters or 1 barrel per minute) is available for delivery within a twelve week timeframe. - Dimensions: (will fit in one 20’ shipping container) Electrical requirements: 440 volts, 3 phase, 50/60 hertz Power consumption:...

Open the catalog to page 5All Origin Oil catalogs and technical brochures

-

EWS Algae A12

4 Pages

-

EWS AQUA Q60

3 Pages

-

EWS ALGAE A200

4 Pages

-

EWS ALGAE A4

4 Pages

-

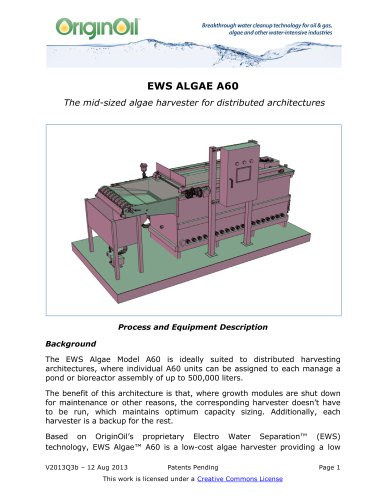

EWS ALGAE A60

4 Pages