Website:

OPTO

Website:

OPTO

Catalog excerpts

Test & Measurement / Materialography Application note Metallurgical Sample Analysis with Opto Machine Vision Microscopes Fig. 1: Metal samples of different geometries embedded in synthetic resin and polished for micro-optical image analysis. Metallography, or more recently materialography (metals plus composites), is the qualitative and quantitative description of the microstructure of metallic materials using microscopic methods. To be able to examine the microstructure under a light microscope, the workpiece must be prepared accordingly in advance. Small pieces must be separated from large components, embedded in a resin, and then ground, polished and, depending on the application, etched. Manufacturers of equipment for specimen preparation are e.g. Struers, QATM, Buehler, Leco, and many more. through the interaction of the surface and the light irradiation used. In reflected-light microscopy, a distinction is made between bright-field and dark-field illumination. In a pure digital microscope, the eyepiece is replaced by a camera chip, as in the imaging module of the compact M platform shown here. In the quality assurance of metallic components, the assessment of damage cases based on material failure or in the development of new materials, these samples are examined and documented with a microscope. These ground-glass samples are opaque to light and must therefore be examined in reflected light in order to detect the smallest defects and features Fig. 2: Coaxial LED serves as incident light bright field illumination, the integrated ring light as incident light dark field illumination www.opto-gmbh.com Opto GmbH • Floriansbogen 2/4 • 82061 Neuried • Germany • Tel: +49 89 8980 55 0 • info@

Open the catalog to page 1

The light sources can be selected and adapted using software, as can the required camera parameters. Fig. 3: IM · compact M with coaxial (left) & ring light illumination (right) Fig. 4: Optimised contours and contrasts of a metal sample for downstream BV The Opto ‘Machine Vision Microscopes – MVMs’ are Imaging Modules of the compact M series. For a classic analysis task, for example, the model with the following specifications would be suitable: • • • • • • USB interface Total magnification: 3.75x Resolution [Lp/mm]: 500 Sensor: 5MP Sony IMX264 Working distance [mm]: 37 Field of view [mm]:...

Open the catalog to page 2

For defect detection, the integration of several illumination types within one sensor is ideal. Depending on the reflection behaviour of the test object, the appropriate illumination concept can be selected. In the case of machine integration, automation can also be realised via SDK. Fig. 5: Defect identification using different illumination concepts - bright field (left) vs. dark field (right) The standard metallic magnifications referred to in the corresponding standards are 50x, 100x, 200x, and 500x, respectively - roughly equivalent to 5x, 10x, 20x, and 50x for a digital microscope....

Open the catalog to page 3

Fig. 8: Polarisation effects provide information about internal stresses in the material In addition to the typical images of the microstructure in the coaxial bright field, especially in the dark field (IM · ring light), impurities or the smallest scratches on the surface are shown in good contrast. Blowholes, pores or cracks are visible as white or black irregularities. For the quality control of samples or the evaluation of sample preparation, the different illumination methods, which can be easily switched via software, are of immense advantage. The colour variants of the IM · MVM...

Open the catalog to page 4All OPTO catalogs and technical brochures

-

IC10-05033CU3101 one page

1 Pages

-

100-MS25-GAN

2 Pages

-

100-MS50-GAN

2 Pages

-

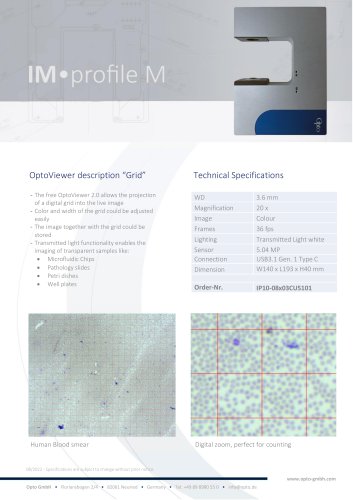

IM•profile M

2 Pages

-

IM•linea M

2 Pages

-

IM•compact_M

2 Pages

-

043-610022

2 Pages

-

043-600505

2 Pages

-

043-1022302-72

2 Pages

-

100-MS50-AN

2 Pages

-

100-MS25-AN

2 Pages

-

Imaging Modules

6 Pages

-

Filterslider

2 Pages

-

Jointed Coupler

1 Pages

-

IP10-06q33CU5101 four pages

4 Pages

-

IP10-06q33CU5101 one page

1 Pages

-

IM•solino 10x12 product info

2 Pages

-

Opto Software

6 Pages

-

Machine Vision Microscope

2 Pages

-

045-100130-01

2 Pages

-

043-112414-C02

2 Pages

-

043-112414-C01

2 Pages

-

Trackstand

2 Pages

-

MMM 4.0

2 Pages

-

043-631003

4 Pages

-

Oblique Viewing Module

4 Pages

-

Machine Vision Objectives

24 Pages

-

100-JC3-66

4 Pages

-

043-490113

2 Pages

-

Microscope Accessories

28 Pages

-

043-30000

2 Pages

-

045-300205

2 Pages

-

043-21300X

2 Pages

-

770-701050

2 Pages

-

043-603020

2 Pages

-

043-112414-50_V2

2 Pages

-

010-310345

1 Pages

-

IM MACHINEVISIONMICROSCOPE

6 Pages

-

045-200208

2 Pages

-

TILTING STAND

2 Pages

-

IMAGE_ERECTION

1 Pages

-

EXTENSION_FOR_COLUMN

1 Pages

-

OBJECTIVE_SLIDER

2 Pages

-

INVERSION_CLAMP

2 Pages

-

FILTER-MODULE

2 Pages

-

100-GS100-02

2 Pages

-

100-GS100-01

2 Pages

-

043-490116 FOR LEICA

1 Pages

-

PROTECTION-GLASS-HOLDER

2 Pages

-

043-300227 RINGLIGHT ADAPTER

1 Pages

-

DRIVE-EXTENSION

1 Pages

-

100-BTC-008

2 Pages

-

045-500084

2 Pages

-

100-CO24-TC

2 Pages

-

043-620102 FOR LEICA

2 Pages

-

770-701042

2 Pages

-

043-112108

2 Pages

-

ScanStand

2 Pages

-

Focus Drive C, Coarse

2 Pages

-

Gliding Stage 100x100mm

2 Pages

-

Bi-telecentric Lens 0.32x

2 Pages

-

Bi-telecentric Lens 0.20x

2 Pages

-

Bi-telecentric Lens 0,16x

2 Pages

-

Bi-telecentric Lens 0,10x

2 Pages

-

Bi-telecentric Lens 0,06x

2 Pages

-

Bi-telecentric Lens 0,05x

2 Pages

-

Bi-telecentric Lens 0,03x

2 Pages

-

CylinderInspector 2D

2 Pages