Website:

OMVE Lab & Pilot Equipment

Website:

OMVE Lab & Pilot Equipment

Catalog excerpts

and have a very low dead volume. Pilot Pasteurization & Sterilization HT320 Pilot Heat Treatment System Small scale, industrial performance The OMVE HT320 HTST/UHT pilot processing system gives research & development, quality assurance and pilot departments access to a unique formula of continuous flow heat treatment processes suitable for a broad range of products. The pilot systems can be customized with different heat exchangers The entire system is operated by a central PLC for easy operation. HTST/UHT systems can be designed to operate at different nominal capacities from 20L/hr up to 200L/hr. Higher capacities are available upon request. Unlike other systems, the OMVE HT320 HTST/UHT pilot systems are modular and can be configured specifically to your project's requirements. The configuration of the HTST/UHT system depends on product and process specifications. All processes can be performed aseptically. Features & Benefits • Industrial A-brand components • Customizable, modular build • Supports different kinds of heat exchangers • In-line operation with other equipment • Full CIP/SIP • Highest level of automation • Broad range of accessories to suit your requirements Working Principle • Baby food • Desserts & puddings • Fruit and vegetable juices & purees • Health & nutritional products • Dairy products • Sauces & soups The HT320 system contains standard a feed hopper, a product pump, a CIP pump, heat exchangers (pre- and main heat with independent control), 2 cooling sections and a touchscreen. The product is pumped from the product feed hopper or external connection to the heat exchangers. In the heat exchangers the product is heated to the set temperature. After the heating the product can go through an optional holding box and be sequentially cooled by the cooling sections. A backpressure valve keeps the system pressurized to prevent boiling during processing. Three stages can be distinguished during operation: sterilization (SIP), production, and cleaning (CIP). Heat Treatment

Open the catalog to page 1

• Mixer in feed tank • Aseptic execution • Conductivity meter • Full CIP upgrade (standard) • Full automated control valves • Data logging facilities • Different kinds of holding cells • Additional heating circuit • Different kinds of heat exchangers Heat Treatment OMVE Netherlands B.V. Gessel 61 3454 MZ, De Meern The Netherlands Tel +31 30 241 00 70 sales@omve.com omve.com Specifications Product Code The OMVE HTST/UHT pilot systems are compatible with different processing equipment, providing the unique ability to simulate an industrial line on a laboratory or pilot scale. All equipment is...

Open the catalog to page 2All OMVE Lab & Pilot Equipment catalogs and technical brochures

-

OMVE CF210 Carbo-Fill®

2 Pages

-

OMVE CF310 Batch Carbonator

2 Pages

-

OMVE HT220 HTST/UHT System

2 Pages

-

OMVE FS211 Clean-Fill ESL

2 Pages

-

OMVE FS212 Asepto-Fill

2 Pages

-

OMVE CRA225 Crystallizer

2 Pages

-

OMVE MPV Batch Cooker

2 Pages

-

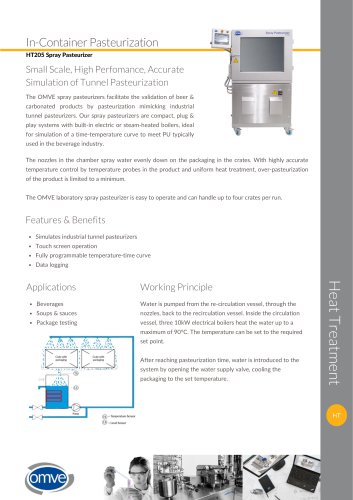

OMVE HT205 Spray Pasteurizer

2 Pages

-

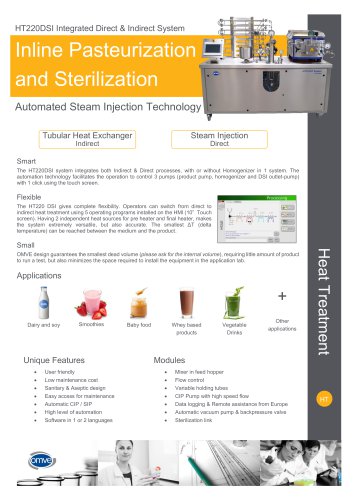

OMVE HT220DSI

2 Pages