Website:

OMVE Lab & Pilot Equipment

Website:

OMVE Lab & Pilot Equipment

Catalog excerpts

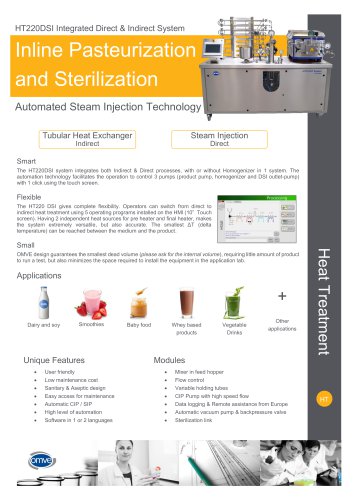

Pasteurization and Sterilization HT220DSI Integrated Direct & Indirect System Automated Steam Injection Technology The HT220DSI system integrates both indirect & direct heating processes, with or without a homogenizer, in one system. The automation technology facilitates the operation to control three pumps (product pump, homogenizer and DSI outlet-pump) with a single click using the touch screen. The HT220DSI provides unparalleled flexibility. Equipped with multiple operating programs, it accommodates both direct and indirect processing options, with or without homogenization (upstream or downstream). These capabilities are intuitively guided step-by-step through user-friendly software accessed via the touch screen (HMI). The inclusion of two independent boilers for indirect processing—one for preheating and another for final heating—enhances the system's versatility and precision. OMVE design guarantees the smallest dead volume, requiring a smaller amount of product to run a test, but also minimizes the space required to install the equipment in the application lab. The HT220DSI was designed with safety & ergonomics in mind and is easy to clean with the built-in CIP process. Features & Benefits • Sanitary & aseptic design • Easy access for maintenance • Automatic CIP/SIP • High level of automation Working Principle • Dairy products • Plant-based products • Functional beverages • Other applications Three stages can be distinguished during the system's operation: sterilization, production and cleaning (CIP). The sterilization (SIP) cycle involves heating the system to a specific temperature (typically 121°C) for a set duration (usually 20 minutes) to effectively eradicate microorganisms. After the SIP cycle the system is ready for processing. The system will stabilised at the set temperature profile with running water, after which production can be started. Following production, the system should be cleaned (CIP) by using the cleaning program. Heat Treatment

Open the catalog to page 1

Optional Accessories • Automatic vacuum pump & backpressure valve • Sterilization link (start-up booster) • Mixer in feed hopper• Variable holding tubes• Data logging Specifications OMVE Netherlands B.V. Gessel 61 3454 MZ, De Meern The Netherlands Tel +31 30 241 00 70 sales@omve.com omve.com 251 Main Street East, Suite L01 Milton, ON L9T 1P1 Canada Disclaimer: no rights can be derived from the content in this brochure.

Open the catalog to page 2All OMVE Lab & Pilot Equipment catalogs and technical brochures

-

OMVE CF210 Carbo-Fill®

2 Pages

-

OMVE CF310 Batch Carbonator

2 Pages

-

OMVE HT220 HTST/UHT System

2 Pages

-

OMVE FS211 Clean-Fill ESL

2 Pages

-

OMVE FS212 Asepto-Fill

2 Pages

-

OMVE CRA225 Crystallizer

2 Pages

-

OMVE MPV Batch Cooker

2 Pages

-

OMVE HT205 Spray Pasteurizer

2 Pages

-

OMVE HT220DSI

2 Pages