Website:

OMVE Lab & Pilot Equipment

Website:

OMVE Lab & Pilot Equipment

Catalog excerpts

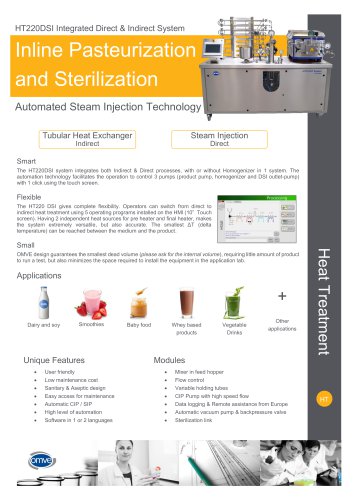

Inline Pasteurization and Sterilization HT220 Lab Indirect Heat Treatment System The compact HT220 system enables you to run a trial with less than 3 liters of product. This reduces the required amount of ingredients, preparation time, start-up time and processing time. Moreover, the HT220 allows you to conduct more trials in a day, improving your R&D productivity. The HT220 features easily accessible heat exchangers (tubular, plates) for indirect processing of liquid food products, allowing you to quickly & effortlessly modify the process configuration. Developers have full process control using OMVE smart software with step-by-step guided programs to run SIP, processing and CIP automatically. Intuitive software in a 9,6" touch screen provides a clear, dynamic overview of the conditions (temperature, flow, pressure), which are recorded in the data logger and can be exported for traceability and quality control. Changeover between recipes is simple with the versatile HT220 thanks to its easy-to-use recipe management system. • Very user-friendly • Full sanitary & aseptic design • Easy accessibility for maintenance • Full CIP/SIP • High level of automation Working Principle Applications Three stages can be distinguished during the system's operation: sterilization, production and cleaning (CIP). The sterilization (SIP) cycle involves heating the system to a specific temperature (typically 121°C) for a set duration (usually 20 minutes) to effectively eradicate microorganisms. After the SIP cycle the system is ready for processing. The system will stabilised at the set temperature profile with running water, after whcih production can be started. Following production, the system should be cleaned (CIP) by using the cleaning program. Heat Treatment • Baby food • Desserts & puddings • Dairy products • Functional beverages • Fruits, vegetable juices & purees • Health & nutritional products • Sauces & soups

Open the catalog to page 1

• Mixer in feed hopper • Flow control/ meter • External data logging • Variable holding tubes • Additional pre-heating boiler • Temperature control cooling • Aseptic execution • Data logging & remote assistance Product Code Pro: Automatic control utilities; manual control product flow OMVE Netherlands B.V. Gessel 61 3454 MZ, De Meern The Netherlands Tel +31 30 241 00 70 sales@omve.com omve.com 251 Main Street East, Suite L01 Milton, ON L9T 1P1 Canada Disclaimer: no rights can be derived from the content in this brochure.

Open the catalog to page 2All OMVE Lab & Pilot Equipment catalogs and technical brochures

-

OMVE CF210 Carbo-Fill®

2 Pages

-

OMVE CF310 Batch Carbonator

2 Pages

-

OMVE FS211 Clean-Fill ESL

2 Pages

-

OMVE FS212 Asepto-Fill

2 Pages

-

OMVE CRA225 Crystallizer

2 Pages

-

OMVE MPV Batch Cooker

2 Pages

-

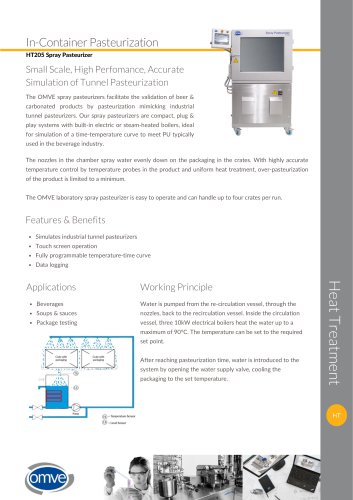

OMVE HT205 Spray Pasteurizer

2 Pages

-

OMVE HT220DSI

2 Pages