Website:

OMVE Lab & Pilot Equipment

Website:

OMVE Lab & Pilot Equipment

Catalog excerpts

Hygienic ESL Filling & Closing Bench FS211 Clean-Fill® When hygienic filling is your priority There are still many laboratories and pilot plants that fill and close a heat-treated product in an open, contaminated atmosphere. Moreover, the filling line has not been part of a CIP and/or SIP procedure. This will create unacceptable variations in the quality of your trials and doesn’t give a representative simulation of an industrial process line. With the specially designed Clean-Fill, OMVE offers the widest range of filling benches for laboratories and pilot plants within the food industry. Different packaging can be filled and closed within the hygienic environment, while minimizing contamination & oxygen in the headspace. The Clean-Fill FS211 is a stainless-steel filler with a filling point. A foot pedal for filling the containers is controlled by an automatic hygienic valve. A temperature sensor is included in the system at the coldest spot as well as a touch screen to display the temperature during sterilization. The condensate cooler ensures controllable cooling of the pressurized water or steam during SIP. Together with an OMVE UHT the highest level of automation during SIP, production & CIP can be reached. Features & Benefits • Sterile down flow filling bench with adjustable front window • Minimum height of the unit, no need for disassembling • Complete stainless-steel system • Integrated cleaning loop - Integrated in sterilization loop CIP/ SIP capable • Aseptic control valves • Touch screen control & Software guided for SMART operation Working Principle • Dairy & dairy alternatives • Alcoholic beverages The Clean-Fill creates a class 100 working environment, ensuring protection for (non-hazardous) products. The continuous down flow, created by the sterile air coming from the HEPA-filter, prevents inflow of contaminated air from outside the filling bench. The hygienic filling nozzle (part of the cleaning and sterilization) is located inside the filling bench. The filling is controlled by the foot pedal or optional volume control on the display. This gives you full freedom to handle the packaging with your hands and minimize contamination.

Open the catalog to page 1

• Closing devices such as: ° Crown cork sealer ° Heat sealer o Can seamer/ Screw Capper • Different heights filling point • Filling flow [volumetric] control • Nitrogen flush for packaging • Larger versions (‘Extended') available FS211 Clean-Fill® - Available in Three Sizes Ultra Clean Filling FS211-11 OMVE Netherlands B.V. Gessel 61 3454 MZ, De Meern The Netherlands Tel +31 30 241 00 70 sales@omve.com omve.com 251 Main Street East, Suite L01 Milton, ON L9T 1P1 Canada Disclaimer: no rights can be derived from the content in this brochure.

Open the catalog to page 2All OMVE Lab & Pilot Equipment catalogs and technical brochures

-

OMVE CF210 Carbo-Fill®

2 Pages

-

OMVE CF310 Batch Carbonator

2 Pages

-

OMVE HT220 HTST/UHT System

2 Pages

-

OMVE FS212 Asepto-Fill

2 Pages

-

OMVE CRA225 Crystallizer

2 Pages

-

OMVE MPV Batch Cooker

2 Pages

-

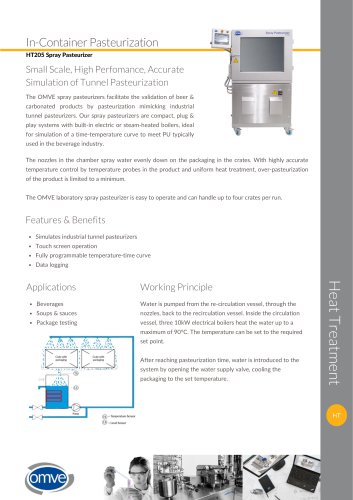

OMVE HT205 Spray Pasteurizer

2 Pages

-

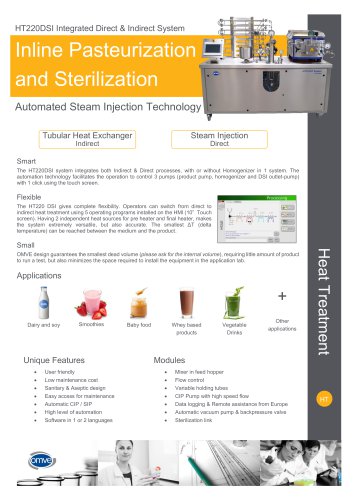

OMVE HT220DSI

2 Pages