Website:

OMVE Lab & Pilot Equipment

Website:

OMVE Lab & Pilot Equipment

Catalog excerpts

Continuous Crystallization CRA225 Crystallizer Creates new opportunities on small-scale The CRA225 unit is an aerator, continuous ice-cream freezer, and crystallizer in one. The texture of your final product is dependent on three factors: the degree of crystallization, the level of aeration and the mechanical force/shear during processing. The system can be executed with an air injection unit, a mixing head, pinworker, scraped surface heat exchangers (SSHEs) and resting tube, ensuring maximum flexibility for your application lab. When using the CRA225 for crystallization of oil and fats, the quality of product is based on consistency, structure, plasticity and hardness. Meeting these specific conditions is directly dependent on the recipe and the process equipment. As the recipes and processes are unique for each product, it is important to have the most flexibility possible from your crystallizer. The hygienic design of the system ensures easy cleaning and a minimum risk of contamination during processing. Features & Benefits • Easy control by colour touch screen • Maximum flexibility in configurations • Hygienic design • Highest level of automation • Easy dismantling of the SSHE Working Principle • Whipped Cream The product is introduced into the balance tank. From here, a product pump continuously feeds the mix into the system. By injecting air in the inlet the product is aerated with a maximum overrun of 100%. From there, the product is entering the crystallizers, which are scraped surface heat exchangers, chilled with a glycol mixture from an external cooling unit. The intensity of cooling on each crystallizer can be set by a manual flow control valve in the glycol line. The resting tube gives additional crystallization time to the product. An air operated back pressure valve makes sure the product is under the right pressure. After the back pressure valve the product can be collected. The system includes an integrated CIP (Clean-In-Place) pump for efficient cleaning.

Open the catalog to page 1

Optional Accessories • Mixer in the feed hopper • Additional barrel(s) and pin worker(s) • Controlled aeration with nitrogen • Flow meter (mass or electro-magnetic) • Heating for CIP-purposes • Upgrade in automation • Heat tracing & re-melting Crystallization & Aeration Product code OMVE Netherlands B.V. Gessel 61 3454 MZ, De Meern The Netherlands Tel +31 30 241 00 70 sales@omve.com omve.com 251 Main Street East, Suite L01 Milton, ON L9T 1P1 Canada Disclaimer: no rights can be derived from the content in this brochure.

Open the catalog to page 2All OMVE Lab & Pilot Equipment catalogs and technical brochures

-

OMVE CF210 Carbo-Fill®

2 Pages

-

OMVE CF310 Batch Carbonator

2 Pages

-

OMVE HT220 HTST/UHT System

2 Pages

-

OMVE FS211 Clean-Fill ESL

2 Pages

-

OMVE FS212 Asepto-Fill

2 Pages

-

OMVE MPV Batch Cooker

2 Pages

-

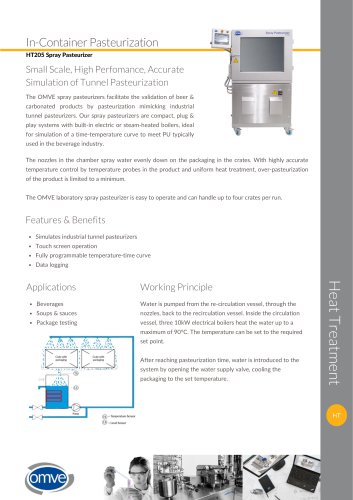

OMVE HT205 Spray Pasteurizer

2 Pages

-

OMVE HT220DSI

2 Pages