Website:

OMVE Lab & Pilot Equipment

Website:

OMVE Lab & Pilot Equipment

Catalog excerpts

Manual Cleaning-in-Place Unit CIP250 Cleaning-in-Place Unit Safe, effective & time-saving R&D labs require efficient and accurate CIP methods to remove product residue from processing plants and to prevent contamination of your test results. The OMVE CIP250 is a compact unit that ensures thorough cleaning of small pilot plants without wasting valuable time dismantling the parts. For efficient cleaning, operators first manually fill the 50L CIP tank with the required detergent mix and set the processing conditions. The CIP250 will circulate the solution/mixture for the required time, depending on the application and the kind of cycle required (alkaline/caustic mix or acid mix circulation). This efficient CIP unit is available with electric heating capabilities. Depending on the size of the equipment volume to be cleaned, OMVE can supply the CIP250 with a 50L vessel to ensure correct minimum flow velocities to properly clean all vessels & pipework. Our CIP unit is suitable to clean OMVE units such as carbonators, fermenters, buffer tanks, blending vessels, UHTs as well as other lab and pilot equipment. Features & Benefits Equipped with electric heated element Safe & secure design to protect the operator's health & safety and the environment (facilities) against splashes Working Principle Cleaning Cycle - Step-by-Step automatically clean OMVE units Step 1. Start of the CIP unit including carbonators, fermenters, Step 2. +/- 10 Min. cold/hot water washing of product from the buffer tanks, blending vessels, UHTs as well as other lab & pilot equipment. system/ tank Step 3. +/- 30 Min. alkaline cleaning at +/- 70°C (depending on the type of detergent) Step 4. +/- 10 Min. cold/ hot water to remove detergents from Automated cleaning of the 50L vessel, CIP pump with high-speed flow up to 2.4mᶾ/hr the equipment Step 5. +/- 30 Min. acid cleaning at +/- 70°C (depending on the type of detergent) Step 6. +/- 15 Min. cold/ hot water to remove detergents from the equipment Step 7. Emptying the tank and pipes

Open the catalog to page 1

CIP250 operating in a full production line OMVE Netherlands B.V. Gessel 61 3454 MZ, De Meern The Netherlands Tel +31 30 241 00 70 sales@omve.com omve.com 251 Main Street East, Suite L01 Milton, ON L9T 1P1 Canada Disclaimer: no rights can be derived from the content in this brochure.

Open the catalog to page 2All OMVE Lab & Pilot Equipment catalogs and technical brochures

-

OMVE CF210 Carbo-Fill®

2 Pages

-

OMVE CF310 Batch Carbonator

2 Pages

-

OMVE HT220 HTST/UHT System

2 Pages

-

OMVE FS211 Clean-Fill ESL

2 Pages

-

OMVE FS212 Asepto-Fill

2 Pages

-

OMVE CRA225 Crystallizer

2 Pages

-

OMVE MPV Batch Cooker

2 Pages

-

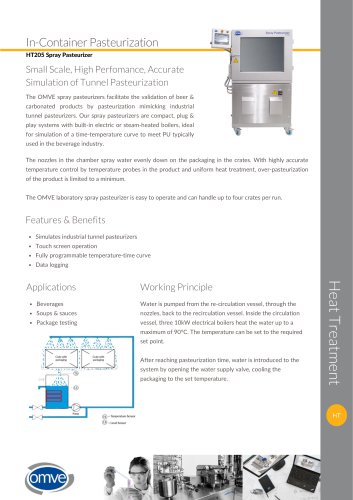

OMVE HT205 Spray Pasteurizer

2 Pages

-

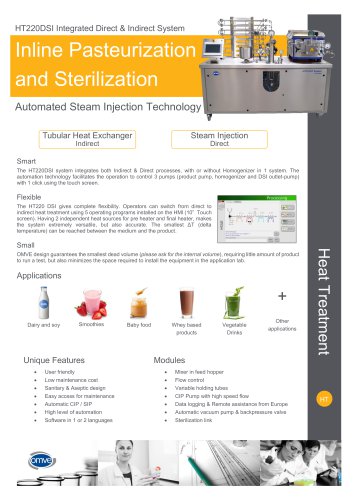

OMVE HT220DSI

2 Pages