Website:

OMVE Lab & Pilot Equipment

Website:

OMVE Lab & Pilot Equipment

Catalog excerpts

Cold Aseptic Filling & Closing Bench When shelf life is your priority There is a growing demand for aseptic filling of liquid products into containers without making use of hot fill or using preservatives and still maintaining an extended shelf life. A frequent problem, especially on small scale, is the sampling, packaging and storage of products without introducing risk of contamination. The OMVE Asepto-Fill® includes all equipment and a detailed step-by-step methodology to assist the operators in filling sterile. Unique features • Isolated filling chamber with a small controlled over-pressure Complete step-by-step instructions to ensure aseptic conditions are maintained User controlled operation with PLC supervision Works with a wide range of containers and sealing devices No chemical sterilization of packaging with risk of contamination The OMVE Asepto-Fill® comprises a container with packaging, a sealed working chamber and an outlet air-lock. For aseptic processing an entire system must be cleaned and sterilized. The sterilization process is a predefined series of operations, all of which need to be completed to ensure commercial sterility. Step-by-step The containers are brought into the container holder and, as a whole, sterilized by gamma radiation treatment (this has to be done at an external company). The sealed container holder can be joined with the working chamber. The working chamber has first to be cleaned and can then be sealed. The gamma-radiated container holder is attached to the chamber. The working chamber is disinfected manually. All inside surfaces of the chamber are disinfected with ethanol or water peroxide. By introducing sterile air into the chamber and a small controlled overpressure is created to prevent contamination from the environment. The PLC is guarding the sterile air flow and whether all the doors are sealed. The product line is sterilized by pressurized hot water or steam (e.g. 121°C for 20 min). A by-pass tube is manually fitted from the filling heat to a drainage point outside of the working chamber. The UHT processing system (used to heat treat the product before filling) is set to provide pressurized hot water or steam at the set sterilization temperature. The temperatures at the coldest spot are monitored by the PLC of the Asepto-Fill®. Filling Systems

Open the catalog to page 1

Ready for production. After cleaning and sterilization the UHT system is switched to product processing (ensuring that the main heat temperature does not drop below sterile limits). Containers are manually removed from the container-holder, placed under the filling nozzle, filled and sealed. These containers are removed via the outlet air lock without exposing the chamber to atmospheric contamination. During this complete procedure the operator is guided step-by-step by the control system. Standard accessories • Flow controlled filling system • Different closing devices • Nitrogen jet for...

Open the catalog to page 2All OMVE Lab & Pilot Equipment catalogs and technical brochures

-

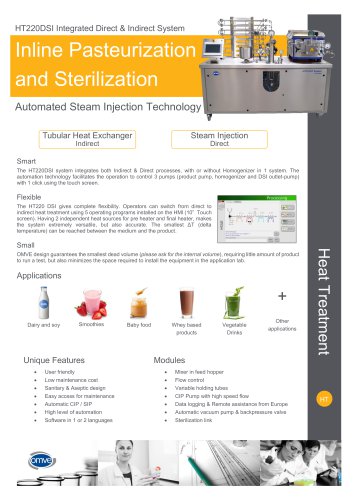

HT220DSI

2 Pages

-

HT205 Spray Pasteurizer

2 Pages

-

MPV Fermentation Vessel

2 Pages

-

MPV Batch Cooker

2 Pages

-

MPV120-BL - Blending Vessels

2 Pages

-

CRA223 Ice cream freezer

2 Pages

-

CRA221 Lab Aerator

2 Pages

-

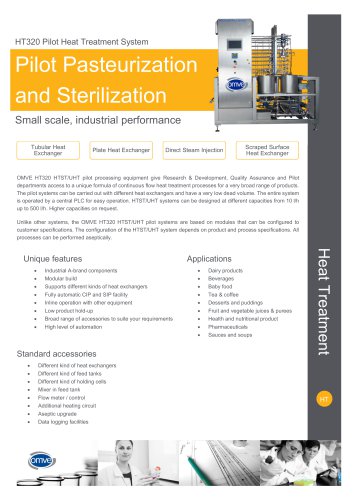

HT320 Pilot HTST/UHT System

2 Pages

-

HT220 HTST/UHT System

2 Pages

-

CF310 Batch Carbonator

2 Pages