Website:

OMVE Lab & Pilot Equipment

Website:

OMVE Lab & Pilot Equipment

Catalog excerpts

DEA310 & DEA320: Batch / Inline Deaerators When low oxygen levels are important In many production processes, the presence of air is inevitable. To attain a better quality product when pasteurizing, homogenizing or filling the product into containers, the presence of air must be avoided or minimized. During product preparations air encapsulation is common, especially on laboratory and pilot scale. A deaerator system optimizes conditions by the removal of air and gas using controlled vacuum and temperature. Benefits of deaerated products: • Improved product shelf life • Increasing product stability • Prevent product oxidation of constituents during heat treatment • Avoid any impairment of constituents such as flavorings, colorants and nutritional compounds • Increase carbonation consistency Unique Features • Suitable for widest range of products • Aroma recovery condenser • Full integration with OMVE equipment • Compact and mobile • Minimum number of rotating parts • Inclusive Aroma condenser Applications • Baby food • Confectionery • Desserts and puddings • Fruit and vegetable juices & purees • Health and nutritional product • Dairy products • Sauces and soups Working Principle The product enters into the vessel at the top. The complete vessel is under vacuum. When entering the vessel, the product surface is increased as much as possible by using a spray nozzle or letting the product flow over a (rotating) disc and along the vessel wall creating a thin product film. The evaporation rate can be improved by heating the product before entering.

Open the catalog to page 1

Kind of de-aeration methods: DEA-SN Spray Nozzle: DEA-SD Static Disc: DEA-RD Rotary Disc: in cases of particle free and low in viscosity. in case of small particles and medium / low viscosity in case of small particles and/or high viscosity Standard accessories • Different de-aeration methods like Spray nozzle, Static disc and Rotary disc • Pump on the inlet or/ outlet. • Aroma condenser to recover extracted “aromas. • Pre-heat exchanger for faster evaporation of entrapped air • Data logging • Double jacketed vessel Type code Why OMVE ✓ Since 1993, we have specialized in supplying...

Open the catalog to page 2All OMVE Lab & Pilot Equipment catalogs and technical brochures

-

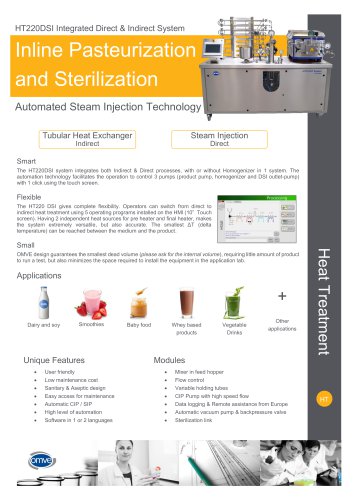

HT220DSI

2 Pages

-

HT205 Spray Pasteurizer

2 Pages

-

MPV Fermentation Vessel

2 Pages

-

MPV Batch Cooker

2 Pages

-

MPV120-BL - Blending Vessels

2 Pages

-

CRA223 Ice cream freezer

2 Pages

-

CRA221 Lab Aerator

2 Pages

-

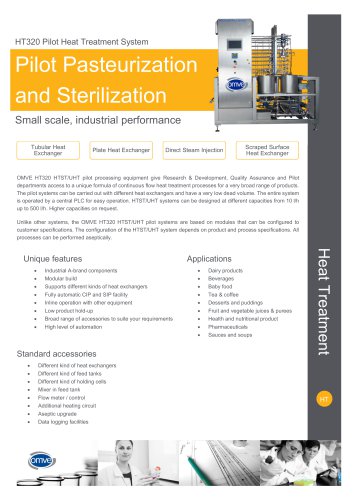

HT320 Pilot HTST/UHT System

2 Pages

-

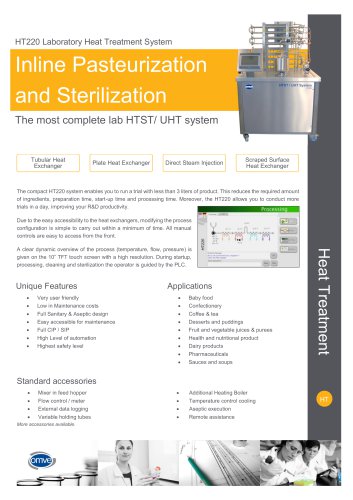

HT220 HTST/UHT System

2 Pages

-

CF310 Batch Carbonator

2 Pages