Website:

OMVE Lab & Pilot Equipment

Website:

OMVE Lab & Pilot Equipment

Catalog excerpts

Batch carbonation For the highest demand in carbonation The OMVE CF310 Pilot carbonator is a highly customizable carbonation system. This system can mix & carbonate a wide variety of products (including products with soft particles). When coupling the CF310 with the OMVE FS205 CounterPressure filler, you can fill and close PET/glass bottles as well as cans. The Batch Carbonator is designed to carbonate pre-mix (finished) product and depending on the options used, handles any type of drink including ice tea, alcoholic beverages and highly foamy products, such a beer. The OMVE Batch Carbonator brings new opportunities in to the area of: • Hygienic & Aseptic Carbonation of beverages • Carbonated products with small soft particles or fibers Carbonation of large batches to fill with a small automated filling line Increase the output by using 3 carbonation vessels (1x filling, 1x carbonate, 1x cleaning) The system is not only suitable for carbonation, but also for mixing and dosing the different products in a hygienic pressurized vessel. Accurate control of carbonation parameters Soft drinks Capability to produce many types of RTD’s Beer & Alcoholic drinks Touch screen control Juices & Concentrates Automatic cleaning programs Working Principle The gas is injected into the product using a special designed injector. This achieves excellent absorption of CO2 with minimum foam. The product is saturated to the desired level by an automatic pressure and temperature control. Saturation time is approximate one minute per liter, after which filling can commence. The Batch Carbonator requires for filling a counter pressure filler such as the OMVE Carbo-Fill, OMVE Flexi-fill or an automated counter pressure filling l

Open the catalog to page 1

Standard accessories • External Cooling system • Filling system • Dosing system • Flow control • Aseptic upgrade • CIP unit Specifications Product Codes Vessel Size System Size LxWxH’ Max. pressure Cooling temperature Flow rate CO2 content Cleaning temperature Sterilization temperature Electricity Water supply Compressed air CO2 supply / Nitrogen supply (optional) Drains *Depending on final configuration Carbonation Family Equipment *based on filling carbonated water Why OMVE ✓ Since 1993, we have specialized in supplying manufacturing R&D and pilot-plant equipment. ✓ OMVE is a preferred...

Open the catalog to page 2All OMVE Lab & Pilot Equipment catalogs and technical brochures

-

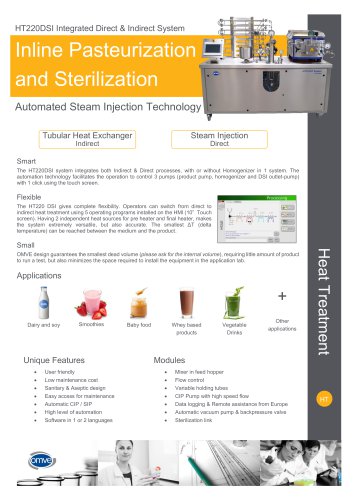

HT220DSI

2 Pages

-

HT205 Spray Pasteurizer

2 Pages

-

MPV Fermentation Vessel

2 Pages

-

MPV Batch Cooker

2 Pages

-

MPV120-BL - Blending Vessels

2 Pages

-

CRA223 Ice cream freezer

2 Pages

-

CRA221 Lab Aerator

2 Pages

-

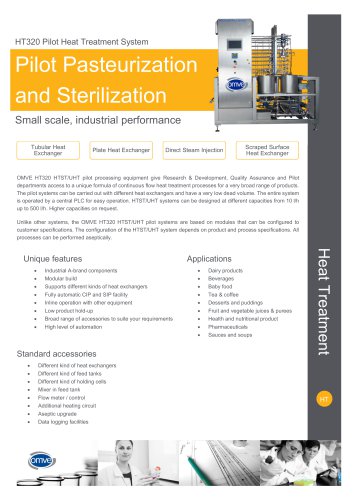

HT320 Pilot HTST/UHT System

2 Pages

-

HT220 HTST/UHT System

2 Pages