Website:

OMPECO SRL

Website:

OMPECO SRL

Catalog excerpts

CONVERTER® NV TREATING WASTE DIRECTLY ON BOARD CERTIFICATIONS ISO 9001 NATO AH649 RINA M.O.G.C. 231 APHIS APHA

Open the catalog to page 3

APPLICATIONS _PRIVATE YACHTS _OFFSHORE PLATFORMS _MERCHANT VESSELS _CRUISE SHIPS _TANKERS _FERRY BOATS THE IDEA Transform unsorted waste into a dry, stable product.

Open the catalog to page 7

WASTE CHARACTERISTICS

Open the catalog to page 8

ORGANIC WASTE 500 kg/m3 DENSITY 100 kg/m3 INFECTED WASTE humidity 500 kg/m3 MUNICIPAL WASTE humidity ORGANIC WASTE humidity HUMIDITY

Open the catalog to page 9

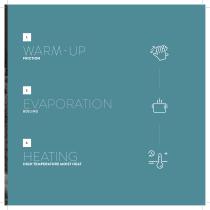

HOW IT WORKS WORKING PRINCIPLES SAFETY Flame free! SAFETY The system does not work under pressure!

Open the catalog to page 10

HIGH TEMPERATURE MOIST HEAT

Open the catalog to page 11

THE PROCESS SEVEN STEPS 30 MINUTES ONLY Converter® equipment is authorized to treat waste through physical modification, reduction of volume, dehydration and reduction of weight. WASTE LOADING The waste is loaded inside the chamber by hand in plastic bags and the lid is closed. The rotor starts and accelerates gradually, as the material is finely ground and the temperature rises quickly to about 100 °C.

Open the catalog to page 12

The heat generated by friction in the material causes the evaporation of the waste moisture and the temperature remains firm at around 100°C. Once all the moisture has been eliminated, the frictional heat causes the temperature of the material to increase to 151°C. STERILIZATION OR PASTEURIZATION The temperature of the material is held firm at 151°C for 3 minutes, under moist heat conditions through controlled water dosage. COOLING DOWN The waste is sprinkled with water in order to lower the temperature of the material to about 100°C. A vacuum pump then lowers the temperature further down...

Open the catalog to page 13

THE RESULT LIGHT AND DRY WASTE BIN IS AN IDEAL BACTERIAL CULTURE Microorganism proliferation and spreading is the common problem connected to the management of the waste because it directly affects the human health. 1 bacteria today At the end of the treatment with the Converter NV the final product is a completely unrecognizable, odorless and sterile flock or “fluff”. The weight is reduced by 50%, and the volume by 80%. If vacuum packed the volume is reduced further and the brickets can be stored for long periods, with no odour, dust or need to refrigerate

Open the catalog to page 14

WASTE MATERIAL includes several hazardous substances which can be eliminated only through thermal processes. *based on the moisture content

Open the catalog to page 15

WITHOUT CONVERTER Usually there are several systems to manage the different waste streams INCINERATOR METAL PLASTIC GLASS

Open the catalog to page 16

EASY WASTE MANAGEMENT NO POLLUTION - ON BOARD STORAGE WITH CONVERTER It is not necessary to do separate waste collection

Open the catalog to page 17

UNRECOGNIZABLE ODORLESS AND PASTEURIZED The waste can be kept without emitting odors for up to 90 days.

Open the catalog to page 18

FLUFF AUTOMATIC VACUUM RDF 3.5 ÷ 4.5 MWh/t* * nominal value NO WASTE STORAGE EASY FLOCK LESS SPACE REQUIRED

Open the catalog to page 19

Converter® NV 200 Converter® NV 100 Converter® NV 60 Converter® NV 30 Converter® NV

Open the catalog to page 21

TECHNICAL DETAILS 400 liters waste organic municipal Specification treatment chamber volume [lt] machine dry weight [Kg] machine footprint [mm - h] electric cabinet weight [Kg] electric cabinet footprint [mm] total installed power [KW] nominal motor power [KW] nominal current [A] peack current [A] electrical consumption [KW/Kg]

Open the catalog to page 23

TECHNICAL DETAILS 200 liters waste organic municipal Specification treatment chamber volume [lt] machine dry weight [Kg] machine footprint [mm - h] electric cabinet weight [Kg] electric cabinet footprint [mm] total installed power [KW] nominal motor power [KW] nominal current [A] peack current [A] electrical consumption [KW/Kg]

Open the catalog to page 25

TECHNICAL DETAILS 100 liters waste organic municipal Specification treatment chamber volume [lt] machine dry weight [Kg] machine footprint [mm - h] electric cabinet weight [Kg] electric cabinet footprint [mm] total installed power [KW] nominal motor power [KW] nominal current [A] peack current [A] electrical consumption [KW/Kg]

Open the catalog to page 27

NO POLLUTANT EMISSIONS Liquids present in the waste are separated and condensed NO WATER CONSUMPTION Can be reduced down to zero SAFE STOCK No dust No odor No fermentation EASY TO USE No special license is needed to operate NO WASTE SEGREGATION Time saving

Open the catalog to page 28

ECOFRIENDLY SUSTAINABLE ECONOMIC

Open the catalog to page 29

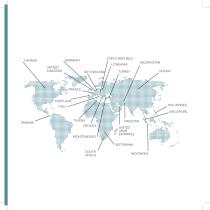

25 COUNTRIES • Our brokers are present worldwide; • Several local distributors operate exclusively in their territories; • Among our clients there are the 5 most important NATO Navies and manufactures of large luxury Yac

Open the catalog to page 30

CZECH REPUBLIC UNITED KINGDOM PORTUGAL PHILIPPINES SINGAPORE PANAMA TUNISIA CROATIA MONTENEGRO PAKISTAN UNITED ARAB EMIRATES BOTSWANA SOUTH AFRICA

Open the catalog to page 31

OMPECO s.r.l. Via Cavalieri del Lavoro, 16 10024 Moncalieri Torino, Italy T. +39 011 02.40.108 www.ompeco.com info@ompeco.com Legal headquarters and billing address: Corso Laghi 26 10051 Avigliana - Torino, Italy Reg. Imp. RI/PRA/2014/46068/800 R.E.A. di Torino 1188899 VAT n° IT11118350013 Information, photos and description contained in this publication are supplied for illustrative purposes and are not binding.

Open the catalog to page 32All OMPECO SRL catalogs and technical brochures

-

AVIATION

21 Pages

-

OIL and GAS waste

4 Pages

-

Unite Mobile

21 Pages

-

URBANO

19 Pages

-

MEDICALE

19 Pages

-

HORECA

36 Pages