Catalog excerpts

Pneumatic and pneumo-hydraulic equipment SPEEDY VISE Pneumatic quick clamping equipment Pneumatic/hydraulic self centering vises Set of modular clamping equipment with hydraulic clamping unit

Open the catalog to page 1

SPEEDY VISE pneumatic quick clamping equipmentmost suitable for mass production on machine centrefeatures 1. Robust contruction of one piece casting of fixed jaw and vise bed. 2. Rigid and high tensile casting of ductile iron FCD60JIS (equal to GGG60) with 60 kg/mm2 or 80.000 psi tensile strength. 3. Most suitable for mass production and to be used on machine centres, milling machines, drilling machines and special purpose machines. 4. Most compact pneumatic mechanism design. No oil, just joint the air supply will do. 5. Most compact in total length of vise with max clamping capacity. 6....

Open the catalog to page 2

SPEEDY VISE most suitable for mass production on machine centre ALWAYS USE FILTERED COMPRESSED AIR. FOR FILTER-LUBRICATOR SEE PAG. 0.38

Open the catalog to page 3

SPEEDY VISE pneumatic quick clamping equipmentaccessories Pair of smooth jaws (HRC 55°-58°) Pair of grooved jaws (HRC 55°-58°)

Open the catalog to page 4

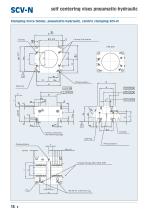

self centering vises pneumatic-hydraulic Clamping force blocks, pneumatic-hydraulic, centric clamping SCV-N - Operating pressure range: - Repeatability accuracy: - Operating temperature range: - Operating principle: - Stroke range: - Mounting: - Housing material: - Material for functional parts: - Actuation: - Connections: - Maintenance: 9 bar with air (6 bar per SCV 250) max 60 bar with olio SCV 66... 100 = 0,01 mm from 5 °C to 60 °C wedge and piston design with mechanically restricted guidance from 4 to 30 mm by means of bores for H7 pins hardened steel hardened steel filtered...

Open the catalog to page 5

self centering vises pneumatic-hydraulic Clamping force blocks, pneumatic-hydraulic, centric clamping SCV-N Closing Central lubrication direct connection see following page

Open the catalog to page 6

self centering vises pneumatic-hydraulic Gripping force Approx. ir consumption Stroke for for double jaw Vers 1 Vers 2 opening closing - The gripping force is the arithmetic sum of the individual forces created at the fingers at "l" distance at 9 bar * Gripping force at 6 bar Hose-free direct connection Central lubrication

Open the catalog to page 7

self centering vises pneumatic-hydraulic Clamping force blocks, pneumatic-hydraulic, centric clamping SCV-N Closing Central lubrication -|//|0.02|C| Direct connection see following page

Open the catalog to page 8

self centering vises pneumatic-hydraulic SCV-NH 13 HYDRAULIC Type ABCDEGHLMPRSUVZXYWJ Ka Hose-free direct connection Hole 1 and 2 Central lubrication

Open the catalog to page 9

self centering vises pneumatic-hydraulicClamping force blocks, pneumatic-hydraulic, centric clamping SCV-N Centering - code BC Version with serrated fingers - code D Load data

Open the catalog to page 10

self centering vises hydraulic "Long stroke" Self centering vise hydraulic "Long stroke" SCV LSH TECHNICAL DATA - Operating pressure range: max 45 bar with oil from cod. 30 10 10 37 to 30 10 10 39 = 0,02 mm with 100 cycles - Repeatability accuracy: from cod. 30 10 10 40 to 30 10 10 42 = 0,03 mm with 100 cycles - Operating temperature range: da 5 °C a 60 °C - Operating principle: wedge and piston design with mechanically restricted guidance from 6 to 72 mm - Stroke range: - Mounting: by means of bores for H7 pins - Housing material: hardened steel - Material for functional parts: hardened...

Open the catalog to page 11

self centering vises hydraulic "Long stroke"

Open the catalog to page 12

- Workpiece weight value at p, = 0.1 e fs = 2. In case of form fit clamping these values may be higher. Gripping force is an aritmetic sum of the individual forces occuring at fingers, distance 15mm at 6MPa.

Open the catalog to page 13

self centering vises hydraulic "Long stroke"MAX. ADM. FORCES AND MOMENTS OF FINGERS 30 10 10 37 2200 100 55 55 DIRECT CONNECTION WITHOUT HOSER 13.14

Open the catalog to page 14

SET TC HYDRO - DUO Modular clamping equipment with hydraulic clamping unit with: SUBPLATE, 2 TC VISES, SEQUENCE VALVES, CONNECTING PIPES and MANIFOLD. SET TC HYDRO - TETRA Modular clamping equipment with hydraulic clamping unit with: SUBPLATE, 4 TC VISES, SEQUENCE VALVES, CONNECTING PIPES and MANIFOLD. SET TC HYDRO - ESA Modular clamping equipment with hydraulic clamping unit with: SUBPLATE, 6 TC VISES, SEQUENCE VALVES, CONNECTING PIPES and MANIFOLD.

Open the catalog to page 15

set of modular clamping equipment with hydraulic clamping unit Code Air/oil foot pump Code 71 66 03 05 Air/oil manual pump Code

Open the catalog to page 16

set of modular clamping equipment with hydraulic clamping unit Working example

Open the catalog to page 17All OML catalogs and technical brochures

-

CIVI SINTERGRIP

16 Pages

-

VCA 5-Axis Machine Tools

14 Pages

-

IMG

44 Pages

-

MODULAR CLAMPING SYSTEMS

20 Pages

-

“GENIUS” & SinterGrip

12 Pages

-

Twin Vices

32 Pages

-

FAST CLAMPS

108 Pages

-

STATIC CHUCKS

16 Pages

-

VP-N

12 Pages

-

FORM HOLDING CLAMPS

18 Pages

-

GENIUS

12 Pages

-

SinterGrip

20 Pages

-

S P E C I A L O F F E R S 2018

20 Pages

-

Zero Point Systems

3 Pages

-

PRODUCTS OFFERS 2013

8 Pages

-

Special jaws and accessories

6 Pages

-

FAST-CLAMPS

109 Pages

-

TOUCHDEX

20 Pages

-

Modular clamping equipment "LC"

10 Pages

-

Tombstones, crankwebs, subplates

36 Pages

-

GENIU5

12 Pages

-

OML Products Offers 2012

6 Pages

Archived catalogs

-

OML Products Offers 2010

12 Pages

-

OML new products 2008

16 Pages

-

Clamping equipment MC

1 Pages

-

Special offers 2008

2 Pages