Website:

OMICRON electronics

Website:

OMICRON electronics

Catalog excerpts

Diagnostic testing and monitoring of power transformers

Open the catalog to page 1

Know the condition of your transformer to get the most out of your During commissioning and operation it is essential that your power transformer is in good condition. Various influences can impact the expected lifetime throughout a transformer's lifecycle. Diagnostic testing and monitoring will help you to determine your asset's condition and choose the right corrective measures to ensure reliable operation and extend the transformer's life expectancy. Negative influences on a transformer's life expectancy > Thermal influences Overload, overheating, ambient conditions > Aging Moisture,...

Open the catalog to page 2

Testing and corrective measures to extend a transformer's life expectancy > Maintain auxiliary components Tap changers, cooling system, breather > Recondition of insulation Drying, oil treatment, oil change > Replace parts Bushings, surge arresters, gaskets, pumps and fans Transformer life expectancy

Open the catalog to page 3

Transformer components and their detectable faults Component Detectable faults Partial breakdown between capacitive graded layers, cracks in resin-bonded insulation Aging and moisture ingress Open or compromised measuring tap connection Partial discharges in insulation Current ratio or phase error considering burden, excessive residual magnetism, non-compliance to relevant IEEE or IEC standard Burden-dependent current ratio and phase displacement Shorted turns Contact problems Mechanical deformation Contact problems in tap selector and at diverter switch Open circuit, shorted turns, or high...

Open the catalog to page 4

Ca di p a s s ci ip t a at n c io e n an fa d ct p o r ow m e ea r f su a c at 50 rem tor/ en Hz D t: or C w 60 in w as Tr Hz i di an tip ng th v sf -u ar or re p sis iab m te er le ta st fre nc tu an e rn qu d m sr e O e at LT as ncy io Ex C ur (T ci T R ve r e m t in ) m i f ic e n g cu Fr ea a t i o t le r eq a su n k a Sh re n ue re tm nc ge or t m en y r re - c ea t es ac irc s po ta uit ure m ns nc im en e em p of e t s t ea da D ra su nc ie y l re e le ct o m / Sw r ic m sse en ee ea s (fr t p De su (FR eq fr re SL m ue eq ag me ) nc ue n ne y) nc tiz t re y at re sp io sp on n on se...

Open the catalog to page 5

The ideal solution for your individual needs and requirements/applic TESTRANO 600 with variable frequency Capacitance and power factor/dissipation factor measurement: DC winding resistance measurement and OLTC verification Transformer turns ratio (TTR) measurement Exciting current measurement Short-circuit impedance / leakage reactance measurement Frequency response of stray losses (FRSL) measurement Demagnetization Dielectric (frequency) response analysis Sweep frequency response analysis (SFRA) Current transformer analysis Partial discharge analysis Partial discharge localization On-line...

Open the catalog to page 6

ation DIRANA Lightweight test set for fast and reliable moisture content determination of oil-paper insulated power transformers. Smart test set for sweep frequency response analysis (SFRA) on power transformer core and windings. Highly accurate and lightweight test set for current transformer calibration and verification. Universal partial discharge (PD) measurement and analysis system Test set for convenient partial discharge localization in power transformers. Portable on-line partial discharge measurement and temporary monitor

Open the catalog to page 7

Capacitance and power factor/dissipation factor measurement Why measure? What can be tested? ü Bushings CTs Leads Tap changer ü Insulation Windings Core Capacitance and power factor/dissipation factor (PF/DF) measurements are performed to investigate the condition of the insulation of power transformers and bushings. Both insulation systems are essential for the reliable operation of the transformer. High oil conductivity, aging and an increase in the water content are symptoms of the degradation process in the insulation. These symptoms also result in an increase of losses, which can be...

Open the catalog to page 8

How does it work? On power transformers, measurements are performed on the main insulation between the windings (CHL) and the insulation from the windings to the tank (CH, CL). The windings are shorted and the test voltage is applied to one winding while the current through the insulation is measured on the opposite winding or the tank. On bushings, the voltage is applied to the main conductor while measuring the current on the measurement tap. The dissipation factor, also called tan(δ), is calculated via the tangent of the angle δ between the measured current and the ideal current which...

Open the catalog to page 9

Capacitance and power factor/dissipation factor measurement Good to know ... After the measurements have been completed, it is beneficial to compare the values to previous results and reference values mentioned in the relevant standards for the tested asset. A rise in capacitance of more than 10 % compared to previous results is normally considered to be dangerous for bushings. It indicates that a part of the insulation distance is already compromised and the dielectric stress to the remaining insulation is too high. An additional voltage tip-up test can detect bad contacts of the bushing...

Open the catalog to page 10

Our solutions ... We offer a wide range of solutions for capacitance and power factor/dissipation factor (tan δ) measurements. They range from mobile solutions for comfortable on-site testing, through high precise solutions for laboratory use, up to dedicated test sets for advanced power transformer condition diagnosis, such as moisture determination. Measurement range Typical application Dedicated condition diagnosis of power transformers on-site and during manufacturing General condition diagnosis of multiple assets on-site and during manufacturing Dedicated power factor/dissipation...

Open the catalog to page 11

DC winding resistance measurement and OLTC verification Why measure? What can be tested? Bushings CTs ü Leads ü Tap changer Insulation ü Windings Core Winding resistance measurements are performed for assessing possible damage in windings or contact problems, such as from the bushings to the windings, the windings to the tap changer, etc. They are also used to check the on-load tap changer (OLTC) as they can indicate when to clean or replace OLTC contacts, or when to replace or refurbish the OLTC itself. Failures can be detected without opening the tap changer compartment. How does it work?...

Open the catalog to page 12All OMICRON electronics catalogs and technical brochures

-

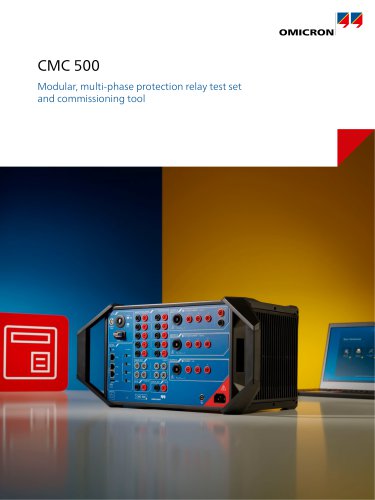

Primary Test ManagerTM

16 Pages

-

MCT 085

2 Pages

-

PDL 650

8 Pages

-

CPC 100

44 Pages

-

OMICRON Products and Solutions

25 Pages

-

InSight

4 Pages

-

MONTESTO 200

16 Pages

-

ISIO 200

8 Pages

-

CMControl R

12 Pages

-

CMControl P

8 Pages

-

CMS 356

2 Pages

-

IEDScout

8 Pages

-

Bode 100 - Technical Data

4 Pages

-

CMA 156

1 Pages