Website:

OMEGA AIR d.o.o. Ljubljana

Website:

OMEGA AIR d.o.o. Ljubljana

Catalog excerpts

Heatless regenerated modular adsorption dryers

Open the catalog to page 1

X-Dry - Heatless regenerated modular adsorption dryers Four individually controlled valves To provide optimum control over the complete drying process four high quality electromagnetic valves are used. Individual control of each valve results in column switch-over without any pressure peaks. Compact control blocks Pressure indicators Compact and robust design of upper and lower control valve block assures reliable operation. Purge air line is mounted on upper check valve block so that purge air nozzle can be replaced if required. During maintenance complete block can be removed from the...

Open the catalog to page 2

ADSORPTION DRYER Compressed air contains contaminants such as water, oil and particulates which must be removed or reduced to the acceptable level based on specific application requirements. Standard ISO8573-1 specifies air purity/quality classes for these contaminants. Humidity (water vapor content) is expressed in the terms of Pressure Dew Point (PDP) where Dew point is the temperature at which air is 100% saturated with moisture. When the temperature of the air is reduced to or below the dew point, condensation will occur. Reduction of water content down to pressure dew point +3°C is...

Open the catalog to page 3

X-Dry - Heatless regenerated modular adsorption dryers 8 X-DRY adsorption dryers have been designed for continuous separation of water vapour from the compressed air thus reducing the pressure dew point. Compact X-DRY series dryer consists of upper and lower control block, controller with LCD display and minimum two pairs of alternately operated columns filled with desiccant. Adsorption takes place under pressure in the first set of columns while the second set of columns regenerate with a portion of already dried compressed air at the ambient pressure. When the first set of columns is...

Open the catalog to page 4

10 min operating cycle When FIX operating cycle is selected or when the dryer is not equipped with a dew point sensor it will operate in pre-set operating cycles meaning length of adsorption and regeneration will be fixed. Energy losses are directly related with an amount of purge air which is used for regeneration. X-DRY energy losses have been optimized due to the 10 minute operating cycle: - 5min = Adsorption - 4 min = Regeneration - 1 min = Pressure build up Extended operating cycle with 12 switch overs per hour also reflects in less wear and thus more reliable operation. If the dryer...

Open the catalog to page 5

Easy maintenance Due to innovative column design desiccant replacement can be done in an easy and fast way. Complete column can be removed from the dryer and then refilled or completely replaced with a new one. When the column is removed clear access to the check valve and the purge nozzle is available. Valves and membranes are located at the back side of the dryer, on the lower control block and can be accessed and replaced in a quick and easy way. STANDARD YEARLY MAINTENANCE Refers to components such as filter elements and expansion silencers. TWO YEAR SERVICE KIT Refers to valve...

Open the catalog to page 6

Technical data Nominal volume flow Refers to 1bar(a) and 20°C at 7 bar operating pressure, inlet temperature 35°C and pressure dew point at outlet -40°C. (2) Outlet flow refers to typical assumption during regeneration phase for operating at nominal inlet flow conditions. Outlet flow includes average air losses of approximately 17,3 %. (3) Reffers to inlet and outlet filter housing. (1) Operating temperature range Voltage, frequency Power consumption Protection class Filter (inlet)* Filter (outlet) Operating pressure range CORRECTION FACTORS - F1 Operating pressure [bar] Operating pressure...

Open the catalog to page 7

Cesta Dolomitskega odreda 10 SI-1000 Ljubljana, Slovenia www.omega-air.si Eurotec Ring 15 D-47445 Moers, Deutschland www.omega-air.de Anićeva 13A HR-10000 Zagreb, Croatia www.omega-air.hr

Open the catalog to page 8All OMEGA AIR d.o.o. Ljubljana catalogs and technical brochures

-

Catalogue - Product overview

72 Pages

-

Screw compressors MA SD 2-3

2 Pages

-

MA SD 7,5-15 VS /BDK

2 Pages

-

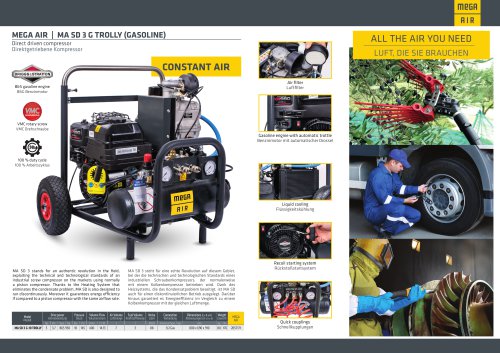

Piston compressors - MEGA AIR

12 Pages

-

Container and Skid units

8 Pages

-

WFIF SERIES

2 Pages

-

WHFIT SERIES

2 Pages

-

MEGA TOOLS

12 Pages

-

MEGA AIR QUALITY OILS

8 Pages

-

CO2-R-DRY series

2 Pages

-

ACW series

1 Pages

-

ACA series

1 Pages

-

RDHP series

2 Pages

-

RDF

2 Pages

-

RDL series

2 Pages

-

RDP series

2 Pages

-

M-DRY series

2 Pages

-

HP-DRY series

2 Pages

-

R-DRY BVL series

2 Pages

-

R-DRY BP series

2 Pages

-

COM-DRY series

2 Pages

-

X-DRY series

2 Pages

-

A-DRY TAC

2 Pages

-

A-DRY BI+BM series

2 Pages

-

PV

2 Pages

-

AIR AND GAS Product overview

2 Pages

-

Compact oxygen generators

2 Pages

-

Compact nitrogen generators

2 Pages

-

SKID based solutions

2 Pages

-

OCI

1 Pages

-

CKL-IHP series

2 Pages

-

SF series

2 Pages

-

WFIW series

2 Pages

-

MSS

2 Pages

-

MDH 400

1 Pages

-

CHI

1 Pages

-

VPG 60

1 Pages

-

FA - flange adapter

1 Pages

-

TD 400M series

1 Pages

-

AOK 50SS

1 Pages

-

EVD series

1 Pages

-

RC-DRY series

2 Pages

-

HPR-DRY series

2 Pages

-

TAC HP series

2 Pages

-

A-CAT series

2 Pages

-

SFH HP

2 Pages

-

TP PED series

2 Pages

-

TP ASME series

1 Pages

-

TP series

1 Pages

-

BS TOWER

1 Pages

-

PETRO-PACK

1 Pages

-

AWS

1 Pages

-

BS 12-3,5

1 Pages

-

AIRWATT series

2 Pages

-

B-AIR plus series

2 Pages

-

OWT

2 Pages

-

OWE/HWE

2 Pages

-

OWB

2 Pages

-

OBE SERIES

2 Pages

-

ECD-B series

2 Pages

-

MDHI 50

1 Pages

-

BF series

2 Pages

-

HPF series

2 Pages

-

AK- assembly kit for filters

1 Pages

-

IHP series

2 Pages

-

PF series

2 Pages

-

EPG 60

1 Pages

-

MDM40

1 Pages

-

OCI

1 Pages

-

AV series

2 Pages

-

SPF series

2 Pages

-

CS /CS SS series

2 Pages

-

SFH /SFH SS series

2 Pages

-

CKL-CHP series

2 Pages

-

MDM60

1 Pages

-

MDH

1 Pages

-

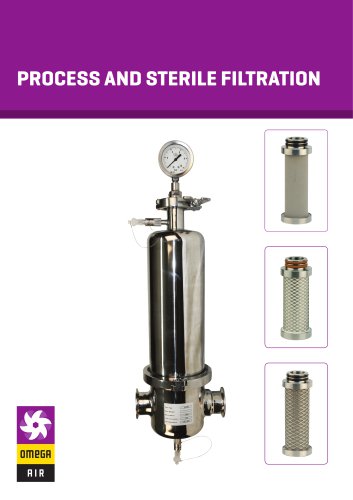

PROCESS AND STERILE FILTRATION

12 Pages

-

SORBEO Adsorbents

2 Pages

Archived catalogs

-

Biogas plants

8 Pages