Website:

OMEGA AIR d.o.o. Ljubljana

Website:

OMEGA AIR d.o.o. Ljubljana

Catalog excerpts

TECHNICAL INFORMATION Volumetric flow rate Air Power connection transmission “ Propulsion power SCREW COMPRESSORS Efficiencies measured in accordance with ISO 1217, Annex C, latest edition. Noise level measured according to ISO 2151. Oil cooler The large area package design ensures excellent heat exchange. The oil cooler is designed to maintain the optimal operating temperature of the oil and air even in the event of difficult operating conditions. The refrigerator is made of aluminum alloy with highly efficient pipe parts. Remote control and connection The Mtronic 100 electronic controller can be connected to a LAN, allowing control and management of the compressor from a remote computer or smartphone. You can use the USB port to export compressor data for analysis and for software updates. Effective sound protection The MA SB 18-55 series is equipped with professional double thick sound insulation material with oil-repellent properties for maximum sound protection and easy cleaning. The high-flow, low-noise electric fan transmits all airflow to a single point and maintains proper thermal balance for all internal components. Compressors for continuous operation Due to their robust design and the use of high-quality components, these compressors are designed for applications where reliable and continuous operation is required. 950472 - 7/6/2022 Applications - Multi-shift production plants - Metal industry, steelworks - Electrical industry - Food industry - Chemical industry - Pharmaceutical industry - Laboratories High performance electric motor The electric motor installed in the compressor is the IE3 PREMIUM EFFICIENCY model, which ensures compliance with the minimum performance requirements (MEPS) set by the EU. The firstclass performance of the electric motor ensures energy savings over time and maximum product reliability. Belt power transmission The MA SB series, which uses a Poly-V belt drive system with cast iron conical pulleys, ensures the best reliability in all operating conditions and limits energy losses. The transmission system also ensures a low noise emission level and perfect alignment of the rotating parts.

Open the catalog to page 1

PRINCIPLES OF OPERATION • In the initial start-up phase, the electric motor (14) (with “star” power supply) rotates slowly. The solenoid valve is not powered, and therefore the suction valve (3) remains closed. The length of this phase is adjustable. The amount of oil can be monitored through the sight glass. • During the second phase of the “delta”, the power supply accelerates the motor until it reaches its operating speed. The solenoid valve is powered and the suction valve (4) opens, which allows air to pass through the suction filter (12) and enter the screw element (2). This starts...

Open the catalog to page 2All OMEGA AIR d.o.o. Ljubljana catalogs and technical brochures

-

Catalogue - Product overview

72 Pages

-

Screw compressors MA SD 2-3

2 Pages

-

MA SD 7,5-15 VS /BDK

2 Pages

-

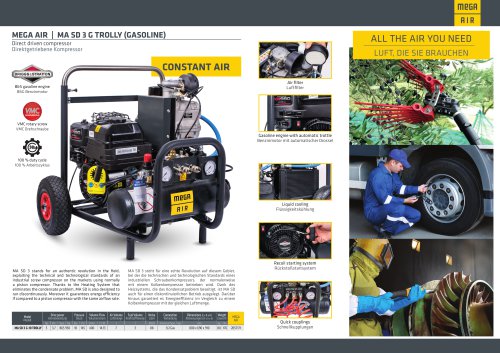

Piston compressors - MEGA AIR

12 Pages

-

Container and Skid units

8 Pages

-

WFIF SERIES

2 Pages

-

WHFIT SERIES

2 Pages

-

MEGA TOOLS

12 Pages

-

MEGA AIR QUALITY OILS

8 Pages

-

CO2-R-DRY series

2 Pages

-

ACW series

1 Pages

-

ACA series

1 Pages

-

RDHP series

2 Pages

-

RDF

2 Pages

-

RDL series

2 Pages

-

RDP series

2 Pages

-

M-DRY series

2 Pages

-

HP-DRY series

2 Pages

-

R-DRY BVL series

2 Pages

-

R-DRY BP series

2 Pages

-

COM-DRY series

2 Pages

-

X-DRY series

2 Pages

-

A-DRY TAC

2 Pages

-

A-DRY BI+BM series

2 Pages

-

PV

2 Pages

-

AIR AND GAS Product overview

2 Pages

-

Compact oxygen generators

2 Pages

-

Compact nitrogen generators

2 Pages

-

SKID based solutions

2 Pages

-

OCI

1 Pages

-

CKL-IHP series

2 Pages

-

SF series

2 Pages

-

WFIW series

2 Pages

-

MSS

2 Pages

-

MDH 400

1 Pages

-

CHI

1 Pages

-

VPG 60

1 Pages

-

FA - flange adapter

1 Pages

-

TD 400M series

1 Pages

-

AOK 50SS

1 Pages

-

EVD series

1 Pages

-

RC-DRY series

2 Pages

-

HPR-DRY series

2 Pages

-

TAC HP series

2 Pages

-

A-CAT series

2 Pages

-

SFH HP

2 Pages

-

TP PED series

2 Pages

-

TP ASME series

1 Pages

-

TP series

1 Pages

-

BS TOWER

1 Pages

-

PETRO-PACK

1 Pages

-

AWS

1 Pages

-

BS 12-3,5

1 Pages

-

AIRWATT series

2 Pages

-

B-AIR plus series

2 Pages

-

OWT

2 Pages

-

OWE/HWE

2 Pages

-

OWB

2 Pages

-

OBE SERIES

2 Pages

-

ECD-B series

2 Pages

-

MDHI 50

1 Pages

-

BF series

2 Pages

-

HPF series

2 Pages

-

AK- assembly kit for filters

1 Pages

-

IHP series

2 Pages

-

PF series

2 Pages

-

EPG 60

1 Pages

-

MDM40

1 Pages

-

OCI

1 Pages

-

AV series

2 Pages

-

SPF series

2 Pages

-

CS /CS SS series

2 Pages

-

SFH /SFH SS series

2 Pages

-

CKL-CHP series

2 Pages

-

MDM60

1 Pages

-

MDH

1 Pages

-

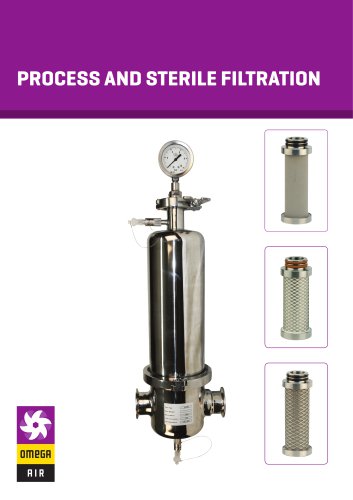

PROCESS AND STERILE FILTRATION

12 Pages

-

SORBEO Adsorbents

2 Pages

Archived catalogs

-

Biogas plants

8 Pages