Website:

OMEGA AIR d.o.o. Ljubljana

Website:

OMEGA AIR d.o.o. Ljubljana

Catalog excerpts

218 OMEGA AIR: Compressed Air and Gas Treatment OWB SERIESAIR-COOLED WATER CHILLERS WITH AXIAL FANS AND SCROLL COMPRESSORS 142 to 574 KW cooling capacity 21/2”to 3” water connections diameter R410A refrigerant DESCRIPTION The OWB range consists of Air cooled water chillers with axial fans for outdoor installation. The OWB family comprises of 12 basic models with cooling capacities ranging from 140 to 570 kW. This allows flexibility of the unit selection, its accessories and the final installation operating conditions. OWB units are particularly suitable for installations where continuous chilled water production is required even for applications in low external ambient temperatures. In this case, it is necessary to use the option of EC condenser fans. The optional free-cooling feature, available in the 160280 kW models, allows the free cooling of the water using a coil cooled by the ambient air. APPLICATIONS • Continuous chilled water production • Applications in low external ambient temperatures REFRIGERANT CIRCUIT The cooling circuit is manufactured by skilled technicians using quality materials and brazing procedures that comply with Directive 97/22/EC. This applies to all models and includes the following components (except those listed above): dehydrating filter, sight glass and humidity indicators, high and low pressure manostats (fixed setting), the high and low pressure gauges, pressure taps for checks and maintenance, evaporation and condensation pressure transducers, refrigerant temperature probes and air / water probes. Forthe models from OWB270 to OWB570, the evaporator has a double refrigerant circuit and a single water circuit. Compared to solutions with independent evaporators, this configuration is particularly effective for partial load applications. HYDRAULIC CIRCUIT The hydraulic circuit consists of an internal evaporator and pipework. It features a differential pressure monostat that protects the evaporator in the event of a loss of water flow.

Open the catalog to page 1

Cooling capacity( Maximum power input (total)1 Power supply Compressor type Evaporator type Brazed plates Condenser type Water connections diameter Tank capacity - Option Expansion vessel capacity - Option P2 Pump power input - Option P2 Pump absorbed current - Option P3 Pump power input - Option P3 Pump absorbed current - Option P5 Pump power input - Option P5 Pump absorbed current - Option [A] Data referred to: water temp, in/out: 20/15°C - Ambient air temp. 25°C - (2) Data referred to unit without pump - (3) Data related to most heavy condition allowed by safety devices - (4) Referred at...

Open the catalog to page 2All OMEGA AIR d.o.o. Ljubljana catalogs and technical brochures

-

Catalogue - Product overview

72 Pages

-

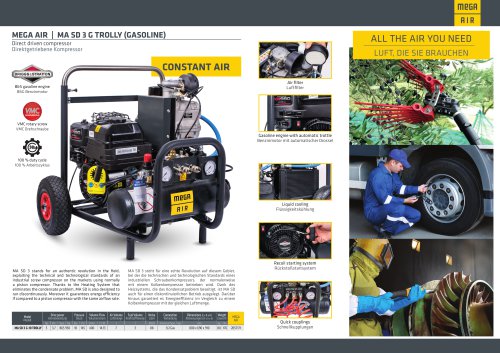

Screw compressors MA SD 2-3

2 Pages

-

MA SD 7,5-15 VS /BDK

2 Pages

-

Piston compressors - MEGA AIR

12 Pages

-

Container and Skid units

8 Pages

-

WFIF SERIES

2 Pages

-

WHFIT SERIES

2 Pages

-

MEGA TOOLS

12 Pages

-

MEGA AIR QUALITY OILS

8 Pages

-

CO2-R-DRY series

2 Pages

-

ACW series

1 Pages

-

ACA series

1 Pages

-

RDHP series

2 Pages

-

RDF

2 Pages

-

RDL series

2 Pages

-

RDP series

2 Pages

-

M-DRY series

2 Pages

-

HP-DRY series

2 Pages

-

R-DRY BVL series

2 Pages

-

R-DRY BP series

2 Pages

-

COM-DRY series

2 Pages

-

X-DRY series

2 Pages

-

A-DRY TAC

2 Pages

-

A-DRY BI+BM series

2 Pages

-

PV

2 Pages

-

AIR AND GAS Product overview

2 Pages

-

Compact oxygen generators

2 Pages

-

Compact nitrogen generators

2 Pages

-

SKID based solutions

2 Pages

-

OCI

1 Pages

-

CKL-IHP series

2 Pages

-

SF series

2 Pages

-

WFIW series

2 Pages

-

MSS

2 Pages

-

MDH 400

1 Pages

-

CHI

1 Pages

-

VPG 60

1 Pages

-

FA - flange adapter

1 Pages

-

TD 400M series

1 Pages

-

AOK 50SS

1 Pages

-

EVD series

1 Pages

-

RC-DRY series

2 Pages

-

HPR-DRY series

2 Pages

-

TAC HP series

2 Pages

-

A-CAT series

2 Pages

-

SFH HP

2 Pages

-

TP PED series

2 Pages

-

TP ASME series

1 Pages

-

TP series

1 Pages

-

BS TOWER

1 Pages

-

PETRO-PACK

1 Pages

-

AWS

1 Pages

-

BS 12-3,5

1 Pages

-

AIRWATT series

2 Pages

-

B-AIR plus series

2 Pages

-

OWT

2 Pages

-

OWE/HWE

2 Pages

-

OBE SERIES

2 Pages

-

ECD-B series

2 Pages

-

MDHI 50

1 Pages

-

BF series

2 Pages

-

HPF series

2 Pages

-

AK- assembly kit for filters

1 Pages

-

IHP series

2 Pages

-

PF series

2 Pages

-

EPG 60

1 Pages

-

MDM40

1 Pages

-

OCI

1 Pages

-

AV series

2 Pages

-

SPF series

2 Pages

-

CS /CS SS series

2 Pages

-

SFH /SFH SS series

2 Pages

-

CKL-CHP series

2 Pages

-

MDM60

1 Pages

-

MDH

1 Pages

-

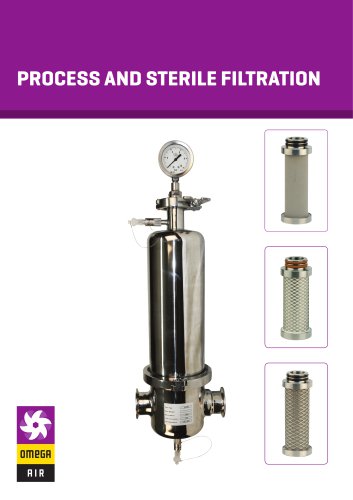

PROCESS AND STERILE FILTRATION

12 Pages

-

SORBEO Adsorbents

2 Pages

Archived catalogs

-

Biogas plants

8 Pages