Website:

OMEGA AIR d.o.o. Ljubljana

Website:

OMEGA AIR d.o.o. Ljubljana

Catalog excerpts

OIL-FREE SCREW COMPRESSORS

Open the catalog to page 1

WHY DO YOU NEED OIL-FREE COMPRESSED AIR? NO RISK OF CONTAMINATION LESS ENVIRONMENTAL IMPACT LOWER MAINTENANCE COSTS LOWER ENERGY COSTS The quality of compressed air can be divided into many levels. Compressing suction dust, moisture, oil, and oil vapors in the compressor can have the following consequences: – loss of production, – scrapping and recalling products, – decline of the brand's reputation, and – decline in consumer interest in your product. Regardless of the type of your line of business, your need for quality compressed air can be complex, but providing a high level of...

Open the catalog to page 2

During the production process, compressed air comes into contact with almost everything, including finished products. It is especially important to avoid contact with oil and oil vapours in the following industries: Medicine and pharmacy In medicine and pharmacy, the purity and quality of the final product is a key factor in the later effectiveness of the products. Many manufacturing processes require virtually zero tolerance for the content of impurities such as oil or moisture in compressed air. It is crucial to minimise the risk of contamination of the product or process. Food and...

Open the catalog to page 3

SUPERIOR COMPONENTS INTEGRATED INTO ONE UNIT MA OF series compressors are produced with latest technologies and highest manufactural standards. MA OF series models Model Fixed speed Frequency speed control Water cooling Suction valve A hydraulic system is used instead of a pneumatic one to regulate the air intake. This prevents the need for periodic replacement of pneumatic components and reduces unnecessary congestion and maintenance costs. Surface treatment of screw elements Organic high temperature resin is thin, hard, antioxidant, and solid. The rotor surface is sandblasted for better...

Open the catalog to page 4

Water cooling Venturi tube Efficient heat exchangers Air/water heat exchangers are available on the MA OF WC models, only water cooling is available on sizes MA OF 55 to 280. The use of air/water heat exchangers provides the option of using waste heat. The pipes are made of 304L SS stainless steel and nickel copper and are more resistant to corrosion. The pipe installation is easy to clean and replace. A venturi tube is installed at the outlet of the screw element to prevent pressure flow, flow pulsation, vibration, and high frequency noise. An efficient heat exchanger system with a...

Open the catalog to page 5

SCREW ELEMENT WITH OIL-FREE DESIGN Lower energy consumption and longer service intervals LEADING TECHNOLOGY The two-stage air compression technology system includes two pairs of high-quality and highperformance GHH rotors that do not use oil to seal the gap between the screws, completely eliminating the presence of oil in the compressed air. The two-stage technology is much more stable and reliable than a single water-lubricated unit, and maintenance costs are low. TWO-STAGE COMPRESSION Two-stage compression with two screw blocks enables stable operation without deviations in air supply....

Open the catalog to page 6

SURFACE TREATMENT OF SCREW ELEMENTS Special surface protection of screw elements provides excellent resistance to temperature changes and provides invaluable protection. Organic temperature resistant resin is thin, hard, antioxidant, and unbreakable. The surface of the rotor is sandblasted before application, which ensures better mechanical adhesion between the rough surface and the coating. Robotic coating ensures even application thickness. The super coating has many advantages: – exceptional compressed air quality, – longer service life of screw elements, – less production downtime, –...

Open the catalog to page 7

COMPRESSOR OPERATING PRINCIPLE Air enters the compressor through a plate filter (12) mounted on the compressor housing and the suction filter (11), then enters the first stage screw element (2) via the suction valve (4), which is opened by means of a suction regulator (5). The inlet pressure of the second stage is shown on the manometer. After leaving the second stage screw element (3), the compressed air first flows through the Venturi pipe, non-return valve (15), and second stage air cooler (10), then through the air-water separator (20), and the condensate is automatically discharged via...

Open the catalog to page 8

COMPONENTS 1) screw block 2) first stage screw element 3) second stage screw element 4) suction valve 5) suction regulator 6) oil filter 7) oil cooler 8) electric fan 9) first stage air cooler 10) second stage air cooler 11) suction filter 12) plate filter 13) electric motor 14) direct drive 15) minimum pressure valve 16) thermostatic valve 17) oil pump 18) oil tank 19) first stage separator 20) second stage separator 21) condensate drain 22) safety valve 23) outlet valve 24) second stage pre-cooler 25) first stage Venturi pipe 26) second stage Venturi pipe 27) first stage heat exchanger...

Open the catalog to page 9

ADVANTAGES EXCEPTIONAL SCREW ELEMENT – quality GHH screw elements, – surface coating of screw elements, – durable and reliable bearings with a service life of 100.000 h, – effective sealing, completely oil-free air, – two-stage compression, – compact design, – energy efficiency, – oil change every 8.000 h, – low maintenance costs, – synchronised gear bearing ensures contactless sealing of rotors, – the second stage screw is made of SS400 stainless steel, which effectively prevents corrosion, – extended service intervals. HIGHLY EFFICIENT COOLING SYSTEM – extremely efficient centrifugal fan...

Open the catalog to page 10

SEPARATE HEAT ZONE SYSTEM – isolated cold and warm zones, – independent working zones for suction, compression, and drainage, OTHER ADVANTAGES – key Siemens control components, – independent oil pumping system, – maximum power 280

Open the catalog to page 11

– 7-inch touch screen. – Complete protection. – Multi-intelligent control, such as setting the operating schedule. – Supports Modbus RTU. – Optional remote control. The controller provides access to all important parameters of compressor operation MAINTENANCE INFORMATION INFORMATION ABOUT ABNORMAL INTERRUPTIONS – fluid replacement – high temperature at the 1st level exit – high temperature at the 1st level exit – lubricant replacement – high temperature at the 2nd level entrance – high temperature at the 2nd level entrance – high temperature at the 2nd level exit – high temperature at the...

Open the catalog to page 12All OMEGA AIR d.o.o. Ljubljana catalogs and technical brochures

-

Catalogue - Product overview

72 Pages

-

Screw compressors MA SD 2-3

2 Pages

-

MA SD 7,5-15 VS /BDK

2 Pages

-

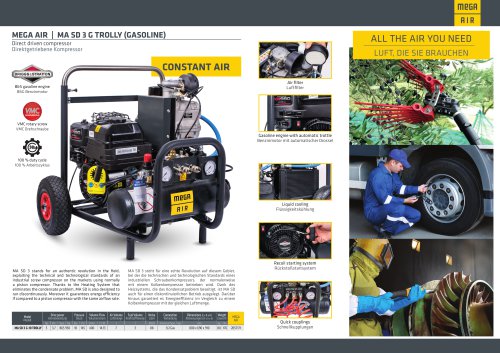

Piston compressors - MEGA AIR

12 Pages

-

Container and Skid units

8 Pages

-

WFIF SERIES

2 Pages

-

WHFIT SERIES

2 Pages

-

MEGA TOOLS

12 Pages

-

MEGA AIR QUALITY OILS

8 Pages

-

CO2-R-DRY series

2 Pages

-

ACW series

1 Pages

-

ACA series

1 Pages

-

RDHP series

2 Pages

-

RDF

2 Pages

-

RDL series

2 Pages

-

RDP series

2 Pages

-

M-DRY series

2 Pages

-

HP-DRY series

2 Pages

-

R-DRY BVL series

2 Pages

-

R-DRY BP series

2 Pages

-

COM-DRY series

2 Pages

-

X-DRY series

2 Pages

-

A-DRY TAC

2 Pages

-

A-DRY BI+BM series

2 Pages

-

PV

2 Pages

-

AIR AND GAS Product overview

2 Pages

-

Compact oxygen generators

2 Pages

-

Compact nitrogen generators

2 Pages

-

SKID based solutions

2 Pages

-

Biogas plants

8 Pages

-

OCI

1 Pages

-

CKL-IHP series

2 Pages

-

SF series

2 Pages

-

WFIW series

2 Pages

-

MSS

2 Pages

-

MDH 400

1 Pages

-

CHI

1 Pages

-

VPG 60

1 Pages

-

FA - flange adapter

1 Pages

-

TD 400M series

1 Pages

-

AOK 50SS

1 Pages

-

EVD series

1 Pages

-

RC-DRY series

2 Pages

-

HPR-DRY series

2 Pages

-

TAC HP series

2 Pages

-

A-CAT series

2 Pages

-

SFH HP

2 Pages

-

TP PED series

2 Pages

-

TP ASME series

1 Pages

-

TP series

1 Pages

-

BS TOWER

1 Pages

-

PETRO-PACK

1 Pages

-

AWS

1 Pages

-

BS 12-3,5

1 Pages

-

AIRWATT series

2 Pages

-

B-AIR plus series

2 Pages

-

OWT

2 Pages

-

OWE/HWE

2 Pages

-

OWB

2 Pages

-

OBE SERIES

2 Pages

-

ECD-B series

2 Pages

-

MDHI 50

1 Pages

-

BF series

2 Pages

-

HPF series

2 Pages

-

AK- assembly kit for filters

1 Pages

-

IHP series

2 Pages

-

PF series

2 Pages

-

EPG 60

1 Pages

-

MDM40

1 Pages

-

OCI

1 Pages

-

AV series

2 Pages

-

SPF series

2 Pages

-

CS /CS SS series

2 Pages

-

SFH /SFH SS series

2 Pages

-

CKL-CHP series

2 Pages

-

MDM60

1 Pages

-

MDH

1 Pages

-

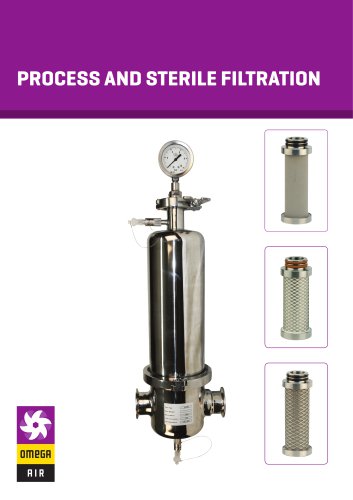

PROCESS AND STERILE FILTRATION

12 Pages

-

SORBEO Adsorbents

2 Pages