Website:

OMEGA AIR d.o.o. Ljubljana

Website:

OMEGA AIR d.o.o. Ljubljana

Catalog excerpts

OMEGA AIR: N-GEN - Nitrogen generators NITROGEN DEMAND PATTERNS Where the consumption rate as a function of time is essentially constant, a PSA nitrogen system is an excellent fit for a steady flow pattern. The PSA unit size can easily be matched to the measured or estimated consumption rate. Furthermore, nitrogen production will be most economical if the unit operates continuously near or at its full capacity. A PSA system is not a good fit for processes with periodic flow pattern, where flow is characterized by peaks and valleys as a function of time. An onsite generator with such variable consumption, particularly if it is sized for a peak flow, will operate at partial capacity or idle for a significant amount of time. This will result in high operating costs and operational inefficiency. However, if the duration of the valleys is short, a PSA combined with a large product buffer tank may be sufficient. A PSA system can be sized to handle most of the nitrogen requirements, supplemented with liquid nitrogen during peak-demand periods. PSA can produce nitrogen at variuos range of purities. The lower the purity, the lower is the cost of nitrogen production. For example, the quality of vegetable oil can be maintained by blanketing with 99,5% nitrogen purity. Normal nitrogen purity for food processing is in the range from 99% to 99,5%. Lower purity nitrogen in the range from 96% to 99% is often used in fire and explosion prevention. High purity with nitrogen content from 99,9 % to 99,999 % is typically used for laser cutting, electronics soldering and pharmaceutical applicatons. The first step in the PSA process is compressed air passing through a combination of filters and an activated carbon tower with the purpose of removing dust, entrained oil and water. The purified air is then directed to one of two adsorption vessels that are packed with carbon molecular sieves (CMS). The remaining impurities such as carbon dioxide and residual moisture are adsorbed by the CMS at the entrance of the adsorbent bed. When the CMS is at high pressure, it selectively adsorbs oxygen, allowing nitrogen to pass through it at the desired purity level. While one vessel is at high pressure to produce nitrogen, the second vessel is depressurized to remove the adsorbed oxygen, which is then vented to the atmosphere. The automatic switching between adsorption and desorption between the two beds enables the continuous production of nitrogen. By adjusting the size of the air compressor and adsorption vessels containing the CMS, a large range of flow and purity combinations can be met. PSAs can economically produce nitrogen gas at flowrates from less than one cubic meter per hour to greater than a few thousand cubic meter per hour at purities ranging from 96% to 99.999%. Pressure testing Electronic soldering Nitrogen flow Fire prevention Injection molding Nitrogen is nontoxic and largely inert gas and that is why it is often mistakenly considered harmless. Notwithstanding by displacing oxygen in air to levels below those required for survival, nitrogen can act as an asphyxiate medium. on request on request on request Industrial nitrogen gas can be produced by either separation of gaseous air using adsorption (PSA) or fractional distillation of liquefied air using cryogenic methods. Chemical blanketing USING NITROGEN SAFELY Operating press.: PDP: Capacity: Explosion prevention Operating press.: up to 13 barg PDP: +3°C / -40°C (lower on request) Capacity: Up to 35 m3/min (higher on request) PRESSURE SWING ADSORPTION Nitrogen is an inert gas that is suitable for a wide range of applications, covering various aspects of chemical manufacturing, processing, handling, and shipping. Nitrogen has low reactivity and it is excellent for blanketing and is often used as purging gas. It can be used to remove contaminants from process streams through methods such as stripping and sparging. Due to its properties it can be used for protection of valuable products against harmful contaminants. It also enables safe storage, usage of flammable compounds and can help prevent combustible dust explosions. CUSTOM MADE CONTAINER NITROGEN AND OXYGEN STATIONS Food processing: - Wine blanketing - Beer dispense - Oil sparging - Fruit storage STANDARD CONTAINER COMPRESSED AIR STATIONS Laser cutting Stationary compressed air stations Nitrogen line PROD. YEAR: PROD. YEAR: OMEGA AIR: N-GEN - Nitrogen generators PROD. YEAR: Regrigeration dryer Activated carbon tower Pressure vessel Nitrogen generator N2 high pressure compressor N2 high pressure receiver Oxygen sensors High quality carbon molecular sieve ensure long service interval. Molecular sieve is also protected from unexpected liquid intake. Robust SIEMENS PLC assures reliable and stable operation and offers variety of settings. The controller is equipped with LCD display which provides all the necessary information about the operation. Two types of high quality oxygen sensors are available as an option: Carbon molecular sieve material is fixed in the column to prevent fast aging and inconveniently dusting. Adsorbent is also protected from unexpected liquid intake. - zirconia sensors have fast response and high accuracy at low oxygen concentration, - electrochemical sensors are appropriate for lower purity’s of the nitrogen. High efficiency inlet and outlet filters Standard version of N-GEN generators are equipped with high efficiency filters. Super fine coalescing filters at the inlet prevents contamination of the adsorbent material while a dust filter at the outlet intercepts the dust generated by the process. Nitrogen basics T +386 (0)1 200 68 00 info@omega-air.si Cesta Dolomitskega odreda 10 SI-1000 Ljubljana, Slovenia www.omega-air.si Nitrogen generators High quality valves Inert, Colourless, Odourless, Tasteless Gas Applications - Blanketing of Chemicals - Pharmaceuticals - Gas Assisted Injection Moulding (GAIM) - Heat Treatment of Ferrous & Non-Ferrous Metals - Inerting of Flammable Liquids - Laser Cutting - Prevention of Dust Explosions - Re-flow and Wave Soldering of PCBs - UV-Curing of Coatings - Food processing – Prevention of oxidation of metals, polymers and chemicals, Our generators are equipped with long life angled seated valves which are important due to high switch count. High flow valves have wide range of piston type actuators for maximum performance at minimum pressure. - Nitrogen does not enter in chemical reactions - Nitrogen prevents oxygen access – Prevention of bacteriological growth (foodstuffs & beverage) – Reduces the risk of combustion and explosion (chemicals, reactions, processes) - Source of Nitrogen LIN = Liquid Nitrogen, GAN = Gaseo

Open the catalog to page 1All OMEGA AIR d.o.o. Ljubljana catalogs and technical brochures

-

Catalogue - Product overview

72 Pages

-

Screw compressors MA SD 2-3

2 Pages

-

MA SD 7,5-15 VS /BDK

2 Pages

-

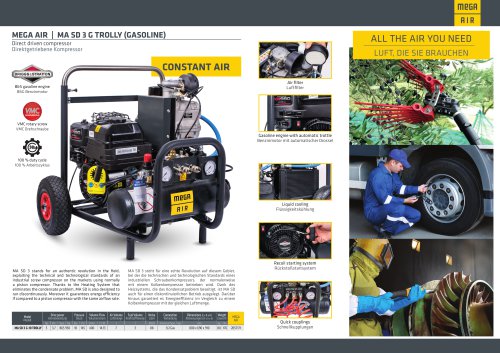

Piston compressors - MEGA AIR

12 Pages

-

Container and Skid units

8 Pages

-

WFIF SERIES

2 Pages

-

WHFIT SERIES

2 Pages

-

MEGA TOOLS

12 Pages

-

MEGA AIR QUALITY OILS

8 Pages

-

CO2-R-DRY series

2 Pages

-

ACW series

1 Pages

-

ACA series

1 Pages

-

RDHP series

2 Pages

-

RDF

2 Pages

-

RDL series

2 Pages

-

RDP series

2 Pages

-

M-DRY series

2 Pages

-

HP-DRY series

2 Pages

-

R-DRY BVL series

2 Pages

-

R-DRY BP series

2 Pages

-

COM-DRY series

2 Pages

-

X-DRY series

2 Pages

-

A-DRY TAC

2 Pages

-

A-DRY BI+BM series

2 Pages

-

PV

2 Pages

-

AIR AND GAS Product overview

2 Pages

-

Compact oxygen generators

2 Pages

-

Compact nitrogen generators

2 Pages

-

SKID based solutions

2 Pages

-

Biogas plants

8 Pages

-

OCI

1 Pages

-

CKL-IHP series

2 Pages

-

SF series

2 Pages

-

WFIW series

2 Pages

-

MSS

2 Pages

-

MDH 400

1 Pages

-

CHI

1 Pages

-

VPG 60

1 Pages

-

FA - flange adapter

1 Pages

-

TD 400M series

1 Pages

-

AOK 50SS

1 Pages

-

EVD series

1 Pages

-

RC-DRY series

2 Pages

-

HPR-DRY series

2 Pages

-

TAC HP series

2 Pages

-

A-CAT series

2 Pages

-

SFH HP

2 Pages

-

TP PED series

2 Pages

-

TP ASME series

1 Pages

-

TP series

1 Pages

-

BS TOWER

1 Pages

-

PETRO-PACK

1 Pages

-

AWS

1 Pages

-

BS 12-3,5

1 Pages

-

AIRWATT series

2 Pages

-

B-AIR plus series

2 Pages

-

OWT

2 Pages

-

OWE/HWE

2 Pages

-

OWB

2 Pages

-

OBE SERIES

2 Pages

-

ECD-B series

2 Pages

-

MDHI 50

1 Pages

-

BF series

2 Pages

-

HPF series

2 Pages

-

AK- assembly kit for filters

1 Pages

-

IHP series

2 Pages

-

PF series

2 Pages

-

EPG 60

1 Pages

-

MDM40

1 Pages

-

OCI

1 Pages

-

AV series

2 Pages

-

SPF series

2 Pages

-

CS /CS SS series

2 Pages

-

SFH /SFH SS series

2 Pages

-

CKL-CHP series

2 Pages

-

MDM60

1 Pages

-

MDH

1 Pages

-

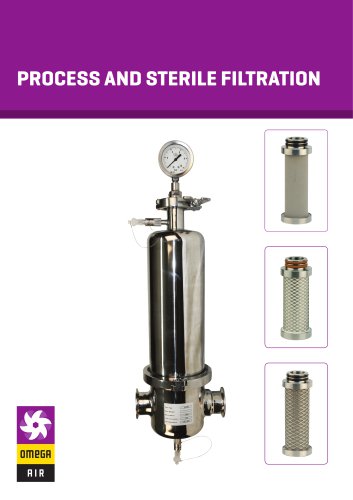

PROCESS AND STERILE FILTRATION

12 Pages

-

SORBEO Adsorbents

2 Pages