Website:

OMEGA AIR d.o.o. Ljubljana

Website:

OMEGA AIR d.o.o. Ljubljana

Catalog excerpts

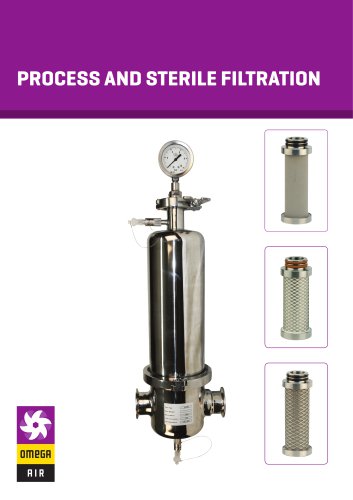

54 OMEGA AIR: Compressed Air and Gas Treatment 1 to 3)6 bar steam pressure 100 °cto135 °c steam operating temperature up to 90 min sterilisation time up to 90 min drying time DESCRIPTION Compressed air piping with high temperature and humidity is a suitable environment for microbial growth. In order to stop microbial activity, filters have to be sterilized. Sterilization can be done in place or in the autoclave. To perform autoclave, sterilization filters need to be removed from the system and due to septic conditions in the atmosphere it is difficult to prevent contamination during re-assembly of the installation. Sterilization in place (SIP) ensures much better results and is more common in the process industry. Steam sterilization is an effective method to stop microbial activity. "Mobile Steam Sterilizer" is designed for easier, cheaper and faster SIP. MSS can be easily connected to any part of installation where sterilization is required. After filter sterilization is completed MSS can simply be disconnected and transported to another location. APPLICATIONS • Food industry • Wine production • Dairies • Small breweries

Open the catalog to page 1

INSTALLATION OF CONVENTIONAL STERILIZATION Scheme of a conventional sterilization in place system. All the equipment surrounded by red line is required to perform sterilization of the filter housing in the upper right corner. Such a fixed steam distribution line connects steam generator to every filter. Sterile INSTALLATION OF MSS ON STERILE FILTER Scheme of a new Mobile Steam Sterilizer connected to a filter. After sterilization cycle is completed flexible hose for steam distribution is disconnected from the filter and complete sterilizer (equipment outlined by a red frame) can be moved...

Open the catalog to page 2All OMEGA AIR d.o.o. Ljubljana catalogs and technical brochures

-

Catalogue - Product overview

72 Pages

-

Screw compressors MA SD 2-3

2 Pages

-

MA SD 7,5-15 VS /BDK

2 Pages

-

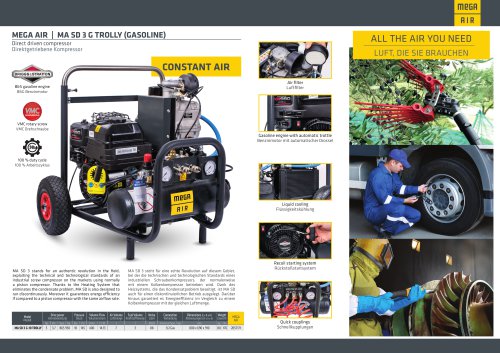

Piston compressors - MEGA AIR

12 Pages

-

Container and Skid units

8 Pages

-

WFIF SERIES

2 Pages

-

WHFIT SERIES

2 Pages

-

MEGA TOOLS

12 Pages

-

MEGA AIR QUALITY OILS

8 Pages

-

CO2-R-DRY series

2 Pages

-

ACW series

1 Pages

-

ACA series

1 Pages

-

RDHP series

2 Pages

-

RDF

2 Pages

-

RDL series

2 Pages

-

RDP series

2 Pages

-

M-DRY series

2 Pages

-

HP-DRY series

2 Pages

-

R-DRY BVL series

2 Pages

-

R-DRY BP series

2 Pages

-

COM-DRY series

2 Pages

-

X-DRY series

2 Pages

-

A-DRY TAC

2 Pages

-

A-DRY BI+BM series

2 Pages

-

PV

2 Pages

-

AIR AND GAS Product overview

2 Pages

-

Compact oxygen generators

2 Pages

-

Compact nitrogen generators

2 Pages

-

SKID based solutions

2 Pages

-

OCI

1 Pages

-

CKL-IHP series

2 Pages

-

SF series

2 Pages

-

WFIW series

2 Pages

-

MDH 400

1 Pages

-

CHI

1 Pages

-

VPG 60

1 Pages

-

FA - flange adapter

1 Pages

-

TD 400M series

1 Pages

-

AOK 50SS

1 Pages

-

EVD series

1 Pages

-

RC-DRY series

2 Pages

-

HPR-DRY series

2 Pages

-

TAC HP series

2 Pages

-

A-CAT series

2 Pages

-

SFH HP

2 Pages

-

TP PED series

2 Pages

-

TP ASME series

1 Pages

-

TP series

1 Pages

-

BS TOWER

1 Pages

-

PETRO-PACK

1 Pages

-

AWS

1 Pages

-

BS 12-3,5

1 Pages

-

AIRWATT series

2 Pages

-

B-AIR plus series

2 Pages

-

OWT

2 Pages

-

OWE/HWE

2 Pages

-

OWB

2 Pages

-

OBE SERIES

2 Pages

-

ECD-B series

2 Pages

-

MDHI 50

1 Pages

-

BF series

2 Pages

-

HPF series

2 Pages

-

AK- assembly kit for filters

1 Pages

-

IHP series

2 Pages

-

PF series

2 Pages

-

EPG 60

1 Pages

-

MDM40

1 Pages

-

OCI

1 Pages

-

AV series

2 Pages

-

SPF series

2 Pages

-

CS /CS SS series

2 Pages

-

SFH /SFH SS series

2 Pages

-

CKL-CHP series

2 Pages

-

MDM60

1 Pages

-

MDH

1 Pages

-

PROCESS AND STERILE FILTRATION

12 Pages

-

SORBEO Adsorbents

2 Pages

Archived catalogs

-

Biogas plants

8 Pages